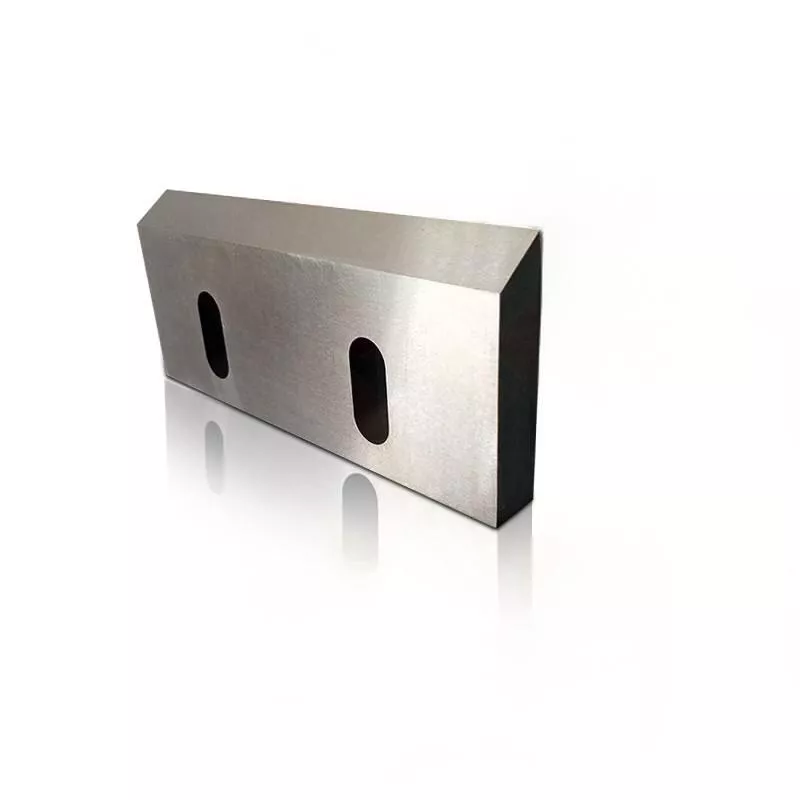

New OEM Blades Knives Herbold Zerma Weima Cumberland Shredder Crusher Granulator Plastic Wood Copper Wire Recycling Machines

OEM replacement blades for Herbold, Zerma, Weima, Cumberland shredders. Compatible with plastic, wood, and copper wire recycling machines. Custom and standard granulator/crusher knives available.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo High Quality Plastic Recycling Shredder Blades & Knives | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

OEM Replacement Blades for Herbold, Zerma, Weima, Cumberland Shredders Precision-engineered shredder blades and granulator knives compatible with major European and North American recycling machine brands. Designed for plastic, wood, and copper wire recycling applications with high-accuracy cutting performance. | |||||||||||||||||

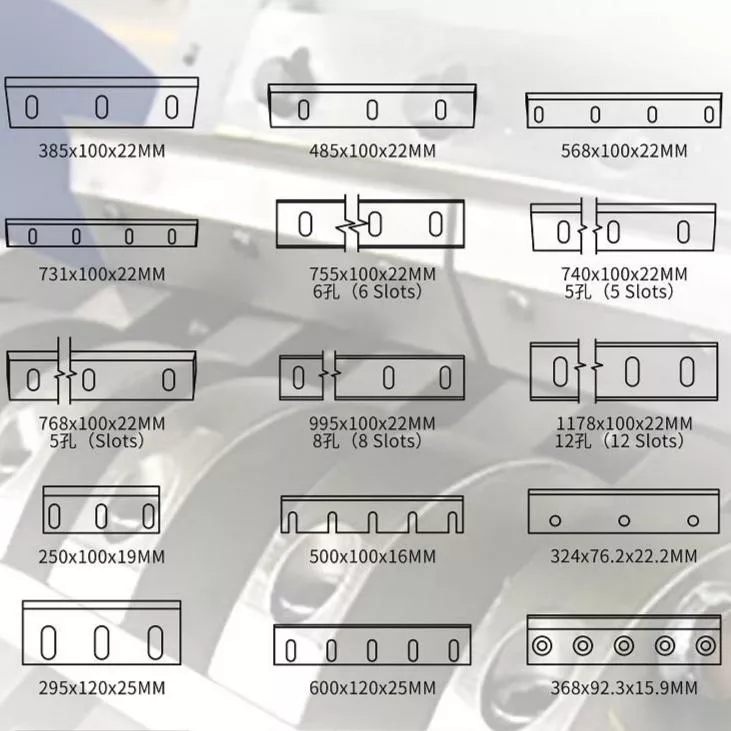

| Key Specifications | Product Name High Quality Plastic Recycling Shredder Blade and Knife Brand Name ShengAo Spare Parts Type Shredder blade Place of Origin Anhui, China Weight 10 KG Material (Standard) Alloy Tool Steel D2, SKD11, 1.2379 Material (Available Options) D2, SKD11, 1.2379, M2, ASP, HSS etc Hardness 56 - 63 HRC Standard Size (Length) 385mm, 486mm, 585mm, etc Standard Thickness 20 mm or customized | ||||||||||||||||

| Quality & Assurance | Quality Control & Documentation Machinery test report: Provided Video outgoing-inspection: Provided Certification: ISO9001:2008, TUV Warranty & Key Selling Points 6 Warranty: 6 Months ✓ Key Selling Point: High-Accuracy MOQ Minimum Order Quantity: 10 pcs | ||||||||||||||||

| Delivery & Lead Time | Standard Packaging Wooden box or customized Standard Quantity-Based Lead Time

Main markets: Europe, North America etc. Lead time starts from order confirmation. | ||||||||||||||||

| Customization & OEM Services | OEM Service Available - OEM replacement blades for Herbold, Zerma, Weima, Cumberland shredders and granulators/crushers. Customization Options

Custom sizes, thicknesses, and materials available upon request. | ||||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our OEM Granulator & Shredder Blades

Our precision-engineered OEM replacement blades and knives are the core cutting components for leading European and North American recycling machinery brands. Designed as direct replacements for Herbold, Zerma, Weima, and Cumberland shredders and granulators, these blades are engineered to restore your equipment to its original cutting performance. We offer both standard sizes (like 385mm, 486mm, 585mm lengths) and fully customized dimensions to ensure perfect compatibility with your specific machine model and application requirements.

Premium Material & Precision Engineering

We manufacture our granulator knives from high-performance alloy tool steels including D2, SKD11, 1.2379, M2, ASP, and various HSS grades. Each material is selected for specific applications: D2 and SKD11 for excellent wear resistance in plastic recycling, and high-speed steels for high-temperature operations. Our blades undergo specialized heat treatment to achieve an optimal hardness range of HRC 56-63, providing the perfect balance between edge retention and toughness. Every blade is precision-machined to achieve high-accuracy dimensions and burr-free edges, ensuring smooth operation and consistent particle size output in demanding recycling environments.

Key Features & Operational Benefits

Designed for maximum performance and longevity, our replacement blades deliver significant operational advantages. The high hardness (HRC 56-63) ensures extended service life between sharpening cycles, reducing maintenance frequency and associated downtime. Our precision manufacturing process guarantees perfect fit and alignment in your original equipment, preventing vibration and uneven wear. The blades' excellent wear resistance handles abrasive materials like filled plastics and copper wire, while their impact-resistant design withstands occasional hard contaminants. These features combine to deliver higher throughput, consistent particle size, and reduced operating costs for your plastic, wood, or copper wire recycling operation.

Application Industries & Material Processing

These versatile blades are engineered for a wide range of size reduction applications across multiple recycling sectors. They are highly effective in processing various plastics (including engineering plastics, films, and lumps), wood waste, copper wire, and other recyclable materials. Specifically designed as OEM replacements for major brands, they are ideal for plastic recycling facilities, wood processing plants, electronic waste (WEEE) recycling operations, cable and wire recovery systems, and general industrial scrap processing. Whether installed in a granulator for fine cutting or a shredder for coarse reduction, our blades provide reliable performance that matches or exceeds original equipment specifications.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customized OEM replacement solutions for virtually any granulator or shredder model. From exact dimensional matching to material specification and hardness requirements, we can tailor blades to your specific machine and material stream. Our commitment to quality is demonstrated through ISO9001:2008 and TUV certified manufacturing processes and comprehensive documentation including official machinery test reports and video outgoing-inspection for every order. Backed by a solid 6-month warranty and a minimum order quantity of just 10 pieces, our blades represent a cost-effective, high-performance solution. Securely packaged in wooden boxes or custom packaging, they arrive ready for installation and immediate productivity in your recycling operation.

Top 5 Granulator Blade Manufacturers for Recycling

Selecting high-quality granulator blades is essential for efficient recycling operations. These manufacturers are recognized for their precision engineering, material expertise, and compatibility with major equipment brands.

ShengAo

A leading manufacturer specializing in high-precision OEM replacement blades for major granulator and shredder brands including Herbold, Zerma, Weima, and Cumberland. Their blades are crafted from premium alloy tool steels (D2, SKD11, 1.2379, M2, ASP, HSS) and heat-treated to HRC 56-63 for optimal performance. They offer complete customization, ISO9001:2008 and TUV certified manufacturing, and comprehensive quality assurance with machinery test reports and video inspections. With a 6-month warranty, 35-day lead time, and global distribution to Europe and North America, they provide reliable aftermarket solutions.

Rapid Granulator

The Swedish pioneer in size reduction technology manufactures original granulator blades for their machines, known for clean cutting with minimal heat generation. Their blade designs focus on preserving material properties during processing, making them ideal for high-quality plastic scrap recycling where material degradation must be minimized. Rapid's blades are engineered for precise particle size control and are popular in applications requiring consistent granulate quality for direct reprocessing.

Herbold

A German manufacturer of size reduction and recycling technology, Herbold produces original granulator blades for their extensive machine range. Their blades are designed for efficient cutting of plastics, including challenging materials like films, fibers, and purgings. Herbold offers various blade geometries tailored to different material types and granulator models, with a focus on wear resistance and consistent performance in continuous industrial recycling operations throughout Europe.

Zerma

Another German specialist in size reduction equipment, Zerma manufactures robust granulator blades with a focus on longevity and cost-effectiveness. Their designs often feature reversible or multi-edge configurations to maximize blade life and reduce total cost of ownership. Zerma blades are particularly popular in plastic recycling operations where continuous, high-volume processing demands durable, reliable cutting components that can withstand abrasive materials and maintain consistent performance.

Cumberland

A long-established North American manufacturer of size reduction equipment, Cumberland produces durable granulator blades for their machinery. Their blades are designed for the North American market with a focus on processing a wide range of plastic materials, including bulky parts and purgings. Cumberland's blade designs emphasize ease of maintenance, consistent particle size, and reliable performance in various plastic processing and recycling applications across the continent.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about OEM granulator blades and shredder knives for plastic, wood, and copper wire recycling.