New Efficient Square Shredder Blades for Recycling Plastic Metal Paper

New efficient square shredder blades optimized for recycling plastic, metal, and paper waste. Enhance your shredder's productivity with our durable, high-performance blade design.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo New Efficient Square Shredder Blades - Bottom Stop Model | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

New Efficient Square Shredder Blades for Recycling Plastic Metal Paper New efficient square shredder blades optimized for recycling plastic, metal, and paper waste. Enhance your shredder's productivity with our durable, high-performance blade design. | |||||||||||||||||||||||||||||||||||||

| Key Attributes | Brand Name ShengAo Type Machine Blade Model Number Bottom Stop Condition New Applicable Industries The recycling station, Power station, Environmental decomposition Place of Origin Anhui, China Core Components material, size Showroom Location None Marketing Type New Product 2024 | ||||||||||||||||||||||||||||||||||||

| Quality Assurance | Inspections & Reports Machinery test report: Provided Video outgoing-inspection: Provided Warranty Details ! Overall Warranty: Unavailable 6 Warranty of core components: 6 Months | ||||||||||||||||||||||||||||||||||||

| Blade Specifications | Available Sizes & Selection

Specifications are in millimeters (mm). The "SELECTED" option indicates the default/recommended size. | ||||||||||||||||||||||||||||||||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | ||||||||||||||||||||||||||||||||||||

| Customization Options | Available Customizations (Minimum Order: 50 sets)

Customization requires a minimum order quantity of 50 sets. Contact us for specific requirements and feasibility. | ||||||||||||||||||||||||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

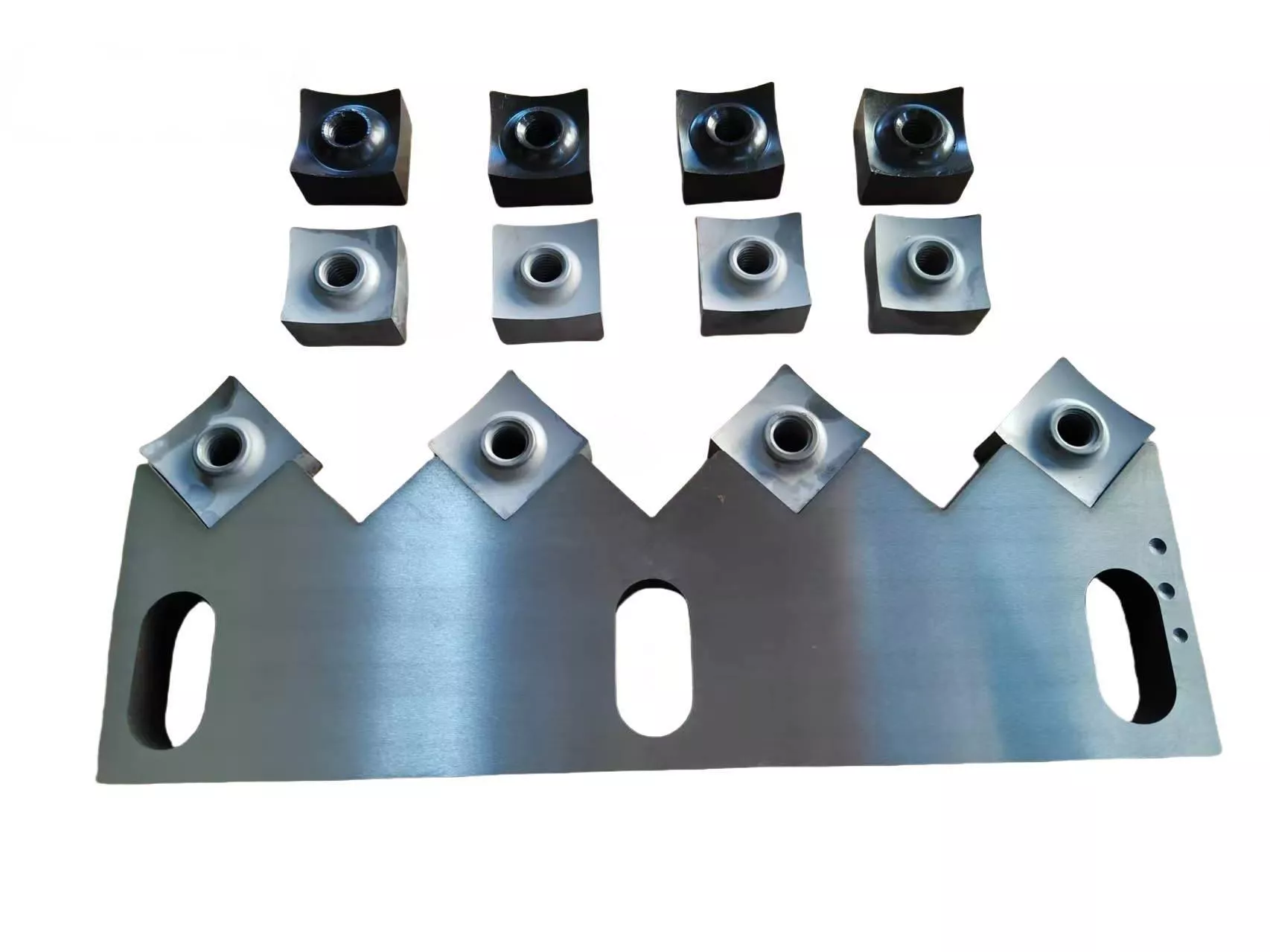

About Our Square Shredder Blades (Bottom Stop Model)

The ShengAo Square Shredder Blade (Bottom Stop Model) is engineered as a core component for industrial single and double shaft shredders. Specifically designed with a square profile and bottom stop feature, these blades provide superior stability and prevent axial movement during high-torque shredding operations. Our blades are used across various industries to efficiently reduce the size of diverse materials for recycling, disposal, or further processing. Engineered for maximum performance and durability in the toughest environments.

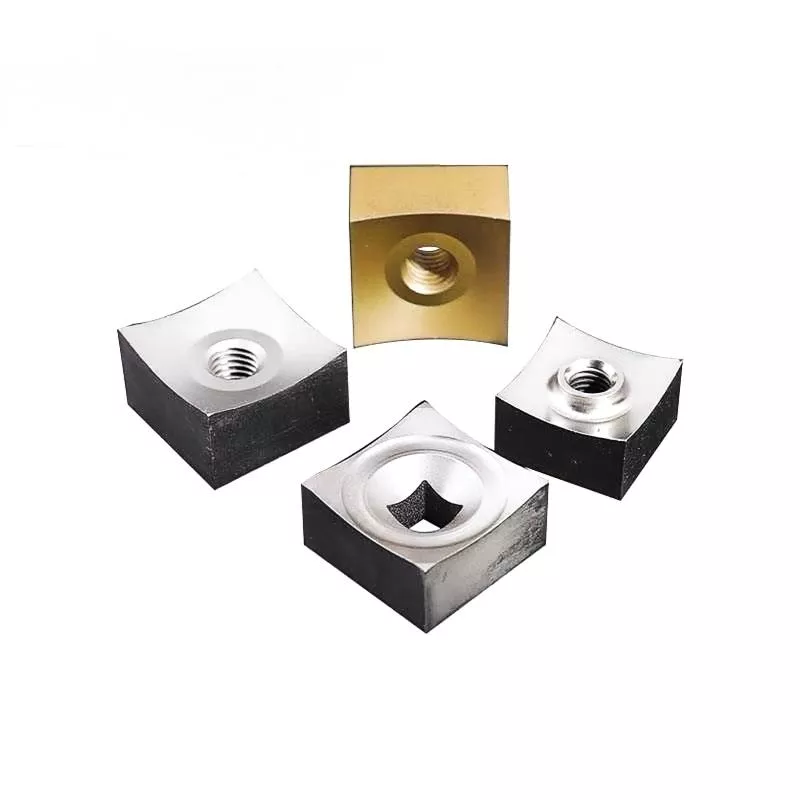

Premium Material & Construction

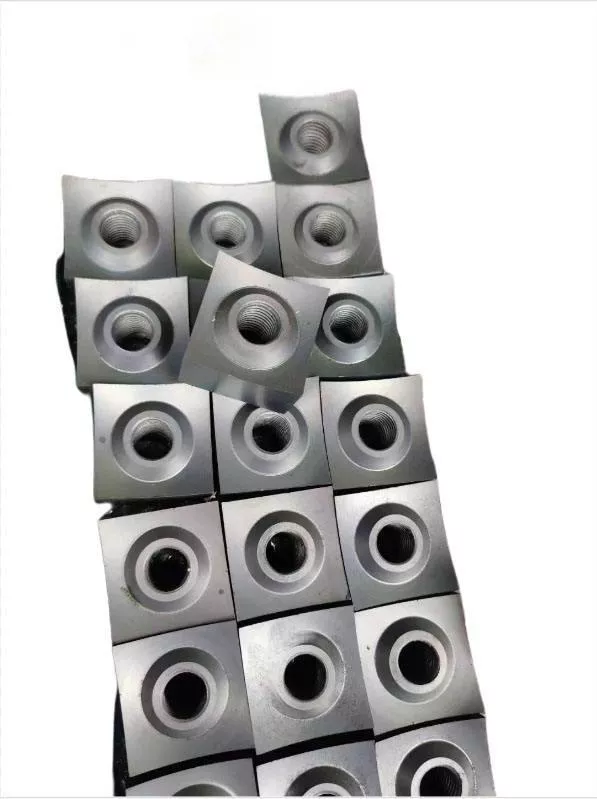

Our square shredder blades are manufactured from premium high-speed steel grades, primarily DC53, D2, and SKD-11. DC53 offers exceptional toughness and wear resistance, making it ideal for shredding mixed and challenging materials like metals and hard plastics. The Bottom Stop design ensures precise positioning on the shredder shaft, eliminating slippage and maintaining optimal cutting geometry. Each blade undergoes precision machining for a burr-free surface, followed by advanced heat treatment to achieve the perfect balance of hardness (typically HRC 58-62) and impact resistance for long-lasting performance.

Key Features & Benefits

Designed for extended service life in continuous, demanding recycling operations. The square shape with bottom stop provides unmatched stability, reducing vibration and wear on the shredder shaft and bearings. Their exceptional wear resistance translates to fewer blade changes, lower maintenance costs, and increased uptime. The impact-resistant design can handle unexpected contaminants like small metals or stones in the waste stream. High rigidity prevents deformation under heavy loads, ensuring consistent shredding size and throughput efficiency throughout the blade's lifecycle.

Application Industries & Materials

These versatile square shredder blades are perfect for a wide range of size reduction tasks in resource recovery and waste management. They are highly effective in processing plastics (bottles, films, lumps), metals (non-ferrous scrap, light gauge), paper & cardboard, textiles, rubber, and municipal solid waste (MSW). Key industries that benefit include recycling stations, power stations (for RDF/SRF production), environmental decomposition facilities, waste management companies, and manufacturing plants with in-house scrap processing needs.

Customization & Quality Assurance

We specialize in providing fully customized square blade solutions. We can tailor dimensions (length, width, thickness, bore size), the specific design of the bottom stop, material grade, and hardness to fit your exact shredder model (like Weima, Vecoplan, Forrec, etc.) and material stream. Our commitment to quality is demonstrated through comprehensive video outgoing-inspection and official machinery test reports for material verification (hardness, composition). Each set of blades is securely packed in robust wooden cases to ensure perfect condition upon arrival, ready for installation and immediate productivity gains.

Top 5 Square Shredder Blade Brands for Recycling

Choosing the right blade brand is critical for shredder efficiency and total operational cost. Here are leading manufacturers known for quality, durability, and innovation in square shredder blade technology.

ShengAo

A premier manufacturer specializing in custom high-speed steel shredder and crusher blades. ShengAo excels in producing precision square blades with features like the bottom stop model, using premium materials like DC53, D2, and SKD-11. Renowned for rigorous quality control, competitive pricing, and the ability to customize for any shredder brand or application, making them a top global supplier for recycling operations.

SSI Shredding Systems

An American industry leader, SSI designs and manufactures complete shredding systems and their proprietary blades. Their square shear blades are engineered for their powerful shredders, known for durability in processing tires, metals, and industrial waste. They offer OEM replacement blades with precise tolerances and advanced metallurgy for their equipment.

WEIMA

A prominent German manufacturer of shredding and briquetting machines, WEIMA produces high-quality original spare parts, including durable square rotor and stator blades. Their blades are known for perfect fit, long service life in plastic and wood recycling, and optimized cutting geometry that matches their machines' performance profiles.

Granutech-Saturn Systems

Part of the worldwide Vecoplan group, this brand offers robust shredding solutions and replacement parts for demanding applications like tire recycling and bulk waste reduction. Their square blades are built for high torque and impact resistance, often featuring specialized coatings or alloys for extended life in abrasive environments.

Eidal / Shred-Tech

Known for innovative shredding technology, this group manufactures heavy-duty industrial shredders and their corresponding wear parts. Their square blades are designed for specific material streams, offering configurations for fine shredding, coarse reduction, and high-volume processing of municipal and industrial waste.

Frequently Asked Questions (FAQs)

Find quick answers to common questions about our Bottom Stop Square Shredder Blades, material selection, and industrial recycling applications.