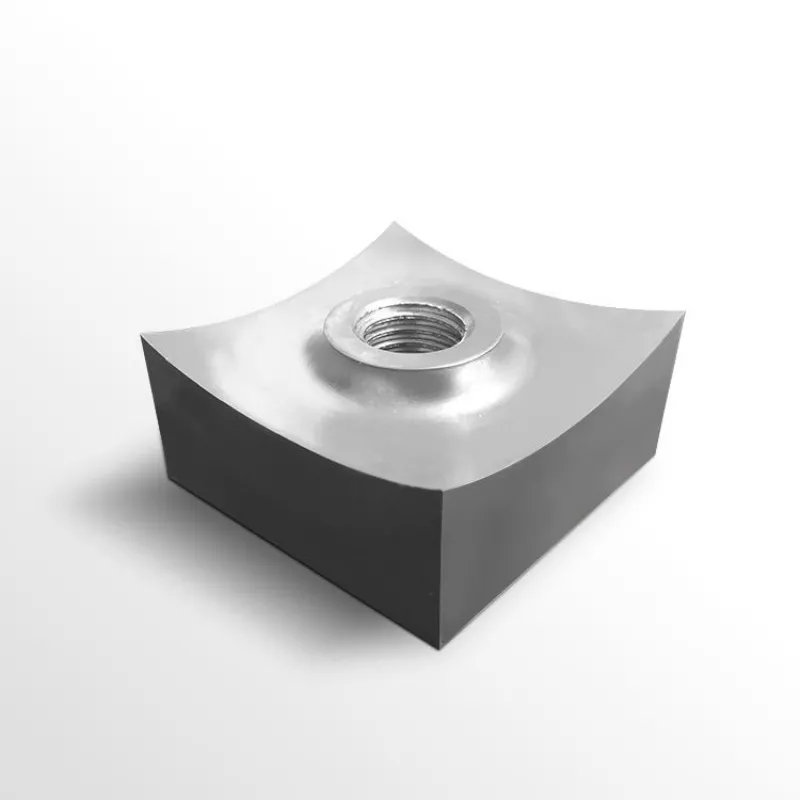

Long Wear Life Pet Shredder Single Shaft Industrial Shredder Blades and Knives

Long wear life PET shredder blades for single shaft industrial shredders. High-performance knives designed for efficient recycling and reduced downtime. Durable and reliable.

Get instant pricing and technical specifications for your project requirements

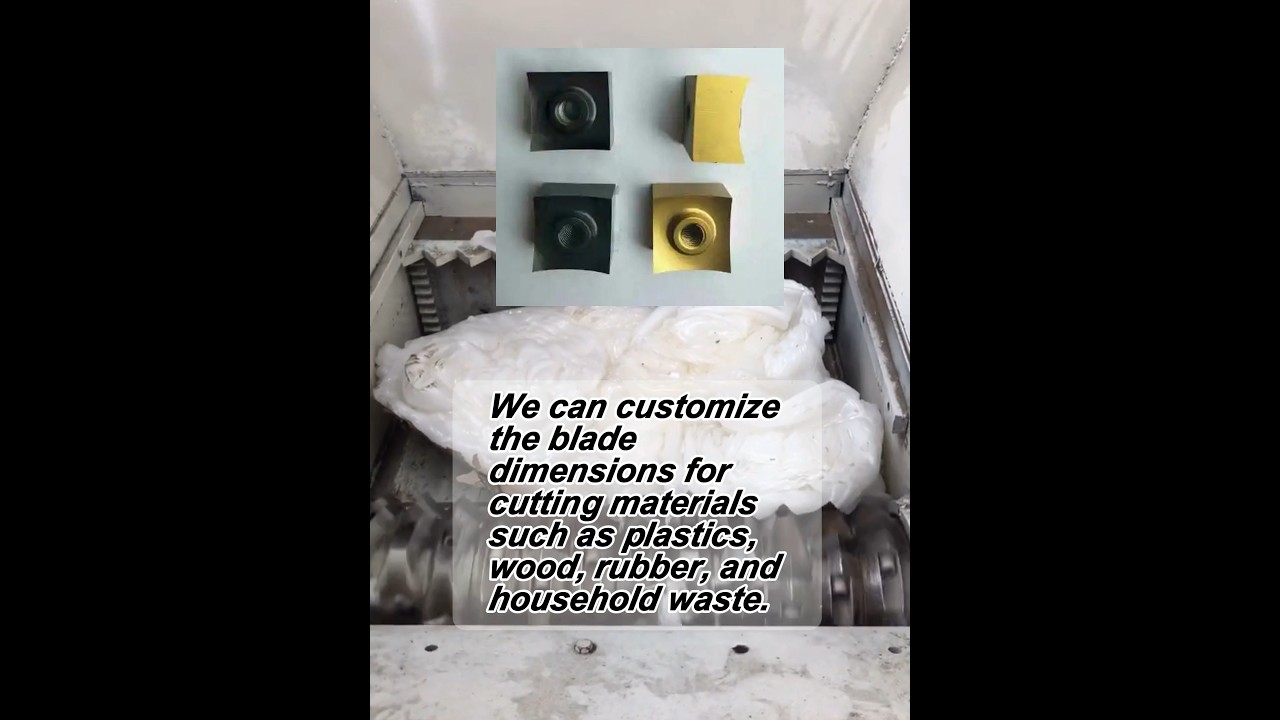

Product Video Demonstration

Product Specifications

| ShengAo Long Wear Life Single Shaft Industrial Shredder Blades and Knives | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

High-Performance Single Shaft Shredder Blades for Recycling Long wear life PET shredder blades for single shaft industrial shredders. High-performance knives designed for efficient recycling of plastic, wood, metal, and cable, ensuring reduced downtime. Durable and reliable construction from high alloy tool steel. | ||||||||||

| Key Product Specifications | Brand Name ShengAo Type Blades Place of Origin China Material 1.2379 / D2 / SKD11 Hardness 58 - 60 HRC Standard Size 34x34x20mm, 40x40x24mm MOQ 100 pcs OEM Service Available Application Cutting waste plastic, wood, metal, cable, copper for recycling. Also suitable for plastic, rubber, metal, and general waste recycling. Note: Thickness, Tolerance, and Size can be customized as per drawing or to exceed OEM specifications. | |||||||||

| Quality & Inspection | Provided Documentation & Services Machinery Test Report: Provided Video Outgoing-Inspection: Provided OEM OEM Service: Available (Customized) Warranty & Components ! Warranty: Unavailable C Core Components: Other (High alloy tool steel) ✓ Packing: Wood boxes (Standard export packaging) | |||||||||

| Delivery & Lead Time | Standard Delivery Terms 30 days after deposit is received Standard Production Lead Time Quantity-Based Lead Time Schedule

Lead time is calculated from the date of order confirmation and receipt of deposit. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

The single shaft shredder rotor blade and counter blade are the core component of industrial shredding systems. Our standard 34x34x20mm and 40x40x24mm square blades are engineered for maximum performance, durability, and long wear life in demanding recycling applications. They are designed to withstand the extreme forces of single-shaft shredders, efficiently reducing the size of various materials for easier handling, recycling, or disposal. These high-performance knives are a reliable solution for continuous operation with minimal maintenance.

Premium Material & Construction

Our blades are manufactured from premium high alloy tool steels, specifically 1.2379, D2, and SKD11. These materials are globally recognized for their exceptional wear resistance, high hardness, and excellent toughness. Each blade undergoes a specialized heat treatment process to achieve an optimal hardness of 58-60 HRC, providing the perfect balance between edge retention and impact resistance. The precise manufacturing ensures a high-quality cutting edge with minimal burrs, promoting smooth material feed and consistent shredding performance in your industrial shredder.

Key Features & Operational Benefits

Designed for longevity and efficiency in the toughest recycling environments, our blades deliver significant operational advantages. The primary key benefits are a long wear life and high-performance cutting. The combination of high alloy steel and precise heat treatment provides superior resistance to abrasion from materials like PET, wire, and metal fragments. This robust construction ensures high rigidity, preventing deformation under heavy load, which maintains cutting accuracy and protects your shredder's drive system. These features translate directly into reduced downtime for blade changes, lower operating costs, and sustained high throughput, maximizing the return on investment for your recycling operation.

Application Industries & Materials

These heavy-duty blades are engineered for a broad range of size-reduction tasks across multiple industries. They are highly effective in processing waste plastics (including PET bottles, HDPE, film, and lumps), wood pallets and construction waste, non-ferrous metals, electrical cables, copper wire, rubber tires, and general industrial waste. Industries that rely on these durable blades include plastic recycling facilities, electronic waste (e-waste) processing plants, metal recycling yards, cable and wire recovery operations, tire recycling, and municipal solid waste (MSW) management. Whether installed in a primary waste reduction line or a dedicated material recovery facility, our single-shaft shredder blades deliver reliable, efficient performance.

Customization & Comprehensive Quality Assurance

We specialize in providing tailor-made OEM blade solutions. While we offer standard sizes, all specifications—including dimensions, thickness, tolerance, and even material grade—can be customized to fit your specific single-shaft shredder model and exceed OEM specifications. Our commitment to quality is transparent and verified: we provide official machinery test reports and video outgoing-inspection for every order, giving you confidence before shipment. Although we do not offer a standard warranty, our focus on premium raw materials and controlled manufacturing ensures a durable, high-performance product. Blades are securely packed in standard export wooden boxes, arriving ready for installation.

Top 5 Single Shaft Shredder Blade Manufacturers

Selecting the right blade manufacturer is critical for the efficiency and uptime of your industrial shredding operation. These companies are recognized for their expertise in material science, engineering precision, and proven durability in the most demanding recycling applications.

ShengAo

A leading specialist in high-wear-life single shaft shredder blades. Their products are crafted from premium high alloy tool steels like 1.2379, D2, and SKD11, heat-treated to 58-60 HRC. Known for standard sizes (34x34x20mm, 40x40x24mm) and full OEM customization capabilities. They emphasize quality assurance with machinery test reports and video outgoing-inspection, ensuring blades meet precise specifications for plastic, wood, metal, and cable recycling. With an MOQ of 100 pcs and a 30-day standard lead time, they cater to both batch buyers and custom projects.

Vecoplan

A German engineering powerhouse renowned for its advanced shredding technology. Vecoplan manufactures high-precision, durable blades for their own single-shaft and multi-shaft shredders, which are used globally in waste wood, plastic, and MSW recycling. Their blades are designed for optimal cutting geometry, low energy consumption, and long service life, often incorporating innovative materials and hardening techniques.

WEIMA

Another leading German manufacturer of robust shredding systems. WEIMA produces heavy-duty single-shaft shredder blades designed for high torque and slow-speed operation, ideal for processing bulky, tough, and mixed materials like industrial waste, plastics, and wood. Their blades are known for reliability, ease of maintenance, and configurations that minimize wear and energy use in continuous 24/7 operations.

SSI Shredding Systems

An American industrial shredding pioneer. SSI designs and manufactures durable shredder blades for their extensive range of equipment, which is used in tire shredding, metal processing, and municipal waste reduction. Their blades are built to handle high shock loads, extreme abrasion, and are often customized for specific, challenging material streams, making them a go-to for North American heavy recycling.

ZERMA

A German manufacturer with a strong focus on size reduction for plastics recycling. ZERMA produces a range of granulators and shredders, along with corresponding blades. Their single-shaft shredder blades are designed for efficient pre-shredding of bulky plastic waste, pipe, and profiles, emphasizing clean cuts and durability to prepare material for downstream granulation.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about Long Wear Life Single Shaft Industrial Shredder Blades for plastic, wood, and metal recycling.