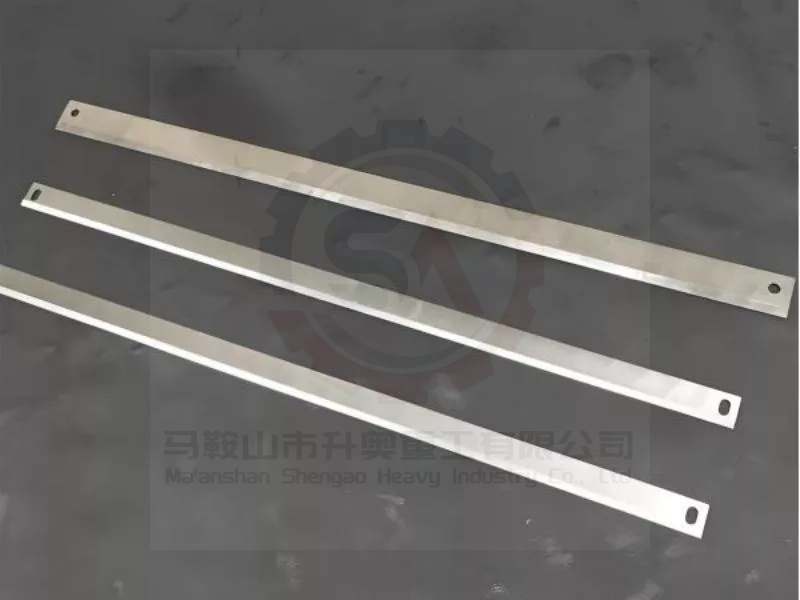

Ma'anshan Sheng Ao Heavy Industry Co., Ltd

Business Type:

Manufacturer/Factory & Trading Company

Main Products:

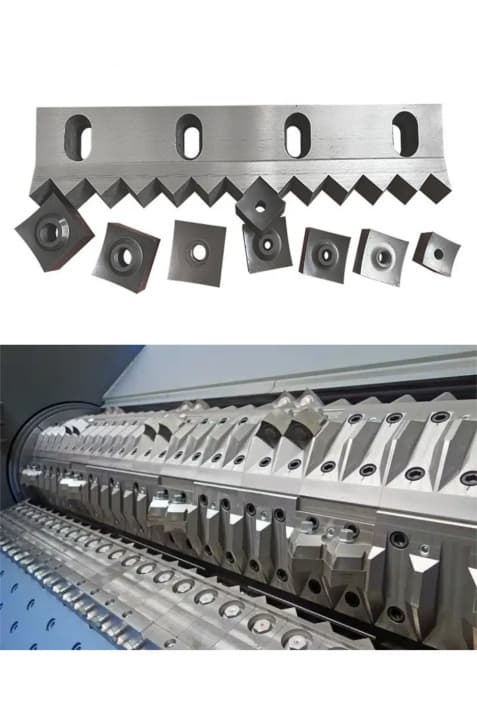

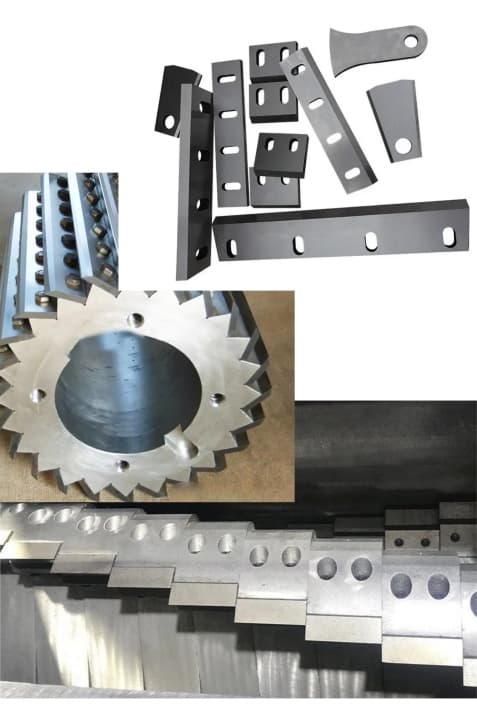

Cutting Circular Blades, Shredder Blades, Plastic Crusher Knives

Address:

Ma'anshan, Anhui, China

Premium manufacturer & supplier in China, offering top quality Cutting Circular Blades, Shredder Blades for scrap metal recycling, and Plastic Crusher Knives for plastic recycling machines. Our blades are known for their anti-aging, anti-oxidation properties and extended durability.

Diamond Member

Verified business licenses

Audited Supplier

Inspected by third-party

Supplier Capability Rating

Secured Trading Service

Ma'anshan Sheng Ao Heavy Industry Co., Ltd