Industrial powerful Crusher Blades

1. Table of Contents

- Introduction

- ShengAo Crusher Blades: Features & Functions

- Blade Design Diagrams and Customization Support

- Primary Industry Applications

- Comparative Analysis: ShengAo vs. Other Major Brands

- Maintenance, After-Sales Support, and Durability

- Conclusion

Introduction

ShengAo's industrial-grade plastic crusher blades are the workhorse of the recycling and manufacturing industry. Engineered for reliability over precision, these robust knives are designed to deliver consistent performance in the demanding task of size reduction for a wide spectrum of plastics. From processing post-consumer waste to handling manufacturing scrap, our blades are built to endure, ensuring your operations run smoothly with minimal downtime. This page details the features, applications, and undeniable value proposition of choosing ShengAo for your plastic crushing needs.

2. ShengAo Crusher Blades: Features & Functions

ShengAo's crusher blades are engineered for reliability and efficiency in demanding industrial environments. They are designed as versatile workhorse components suitable for a wide range of plastic processing applications, from recycling post-consumer waste to handling manufacturing scrap.

2.1. Premium Material Composition

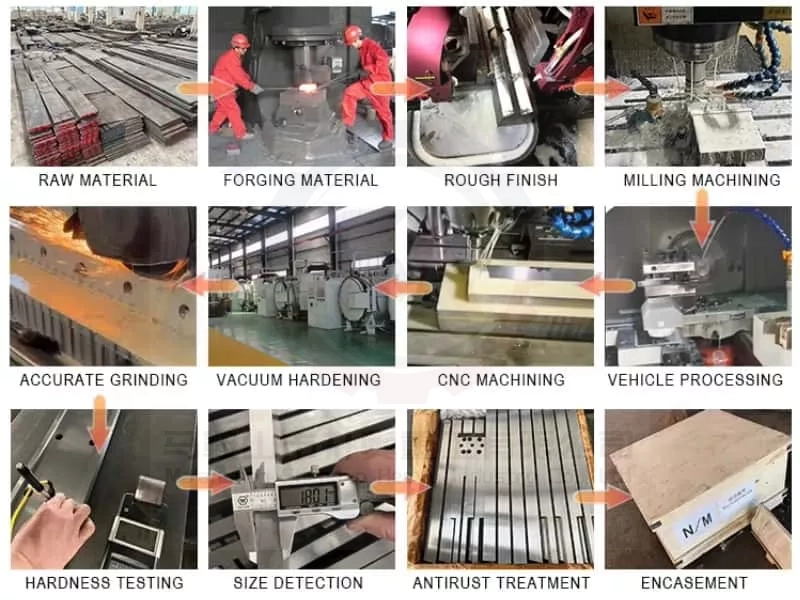

The core of ShengAo's blade performance lies in the selection of robust materials. Primarily manufactured from high-carbon steel and alloy tool steels like SKD11 and D2, these blades achieve a Rockwell Hardness (HRC) of 58-62. This specific hardness range is critical as it provides an exceptional balance between wear resistance and toughness, ensuring the blades can withstand the impact of crushing rigid plastics like PET bottles and ABS scraps without chipping or deforming prematurely. The advanced heat treatment processes further enhance the blade's toughness and edge retention, allowing them to maintain sharpness over extended periods.

2.2. Precision Engineering for Optimal Performance

ShengAo blades are subject to precision grinding using CNC machinery to ensure razor-sharp cutting edges. This precision is not just about sharpness; it directly translates to operational benefits. A precisely sharp blade reduces the force needed to cut, leading to lower energy consumption for the entire crusher. Furthermore, it ensures a uniform particle size of the output granules, which is crucial for efficient melting and pelletizing in downstream processes. The blades are also dynamically balanced to minimize vibration during operation, which contributes to smoother running and reduced wear on the crusher's bearings and other components.

2.3. YouTube Video Demonstration

This video demonstrates the blade's efficiency in a real-world setting, crushing a mix of rigid plastics and films. Key highlights include the smooth feeding process, the consistent granule output, and a post-operation inspection showing the blade's condition after processing a significant volume of material, underscoring its durability.

3. Blade Design Diagrams and Customization Support

ShengAo understands that a one-size-fits-all approach is ineffective in the diverse plastic processing industry. Therefore, the company offers a range of standard designs while emphasizing strong customizability to meet specific machine requirements and material challenges.

3.1. Standard Blade Designs and Technical Schematics

ShengAo produces a variety of standard blade types to suit different crusher configurations and material types. These include straight Rotor Blades (rotating knives), Stator Blades (fixed knives), and specialized designs like Claw Blades for tearing tough, bulky materials. The company provides clear technical schematics for each standard model, detailing critical dimensions such as length, width, thickness, and bore diameter, as well as the precise blade angle. The blade angle is particularly important; a sharper angle is optimal for cleanly cutting soft plastics, while a blunter angle provides more strength for crushing hard plastics.

3.2. Custom Design and Development Services

The cornerstone of ShengAo's service is its customization capability. The company supports OEM and ODM services, allowing clients to tailor blades to their exact needs. This includes customizing dimensions to fit non-standard machine models, adjusting the blade angle or tooth shape for specific materials (e.g., saw-tooth edges for film or smooth edges for sticky plastics), and selecting specialized materials for unique applications. Customers can provide their own drawings, sketches, or even samples for reverse engineering. ShengAo's technical team can also assist in modifying existing designs to improve performance and longevity, offering a collaborative approach to problem-solving.

4. Primary Industry Applications

ShengAo plastic crusher blades are industry-universal components designed for reliability across several key sectors within the plastic economy.

4.1. Virgin Plastic Pelletizing (New Plastic Granulation)

In the production of new plastic products, crushers are used to process off-specification items, injection molding runners and production scrap directly at the manufacturing site. Using ShengAo blades in this closed-loop recycling system ensures efficient size reduction of these materials into uniform regrind flakes. This regrind can be blended with virgin pellets and fed back into the production line, significantly reducing raw material costs and minimizing waste. The durability of ShengAo blades is key here, as they maintain consistent particle size over long periods, which is essential for maintaining the quality of the final product.

4.2. Recycled Plastic Granule Production

This is the most demanding application, where blades encounter contaminated and mixed plastics. ShengAo blades are widely used in dedicated plastic recycling facilities to crush post-consumer items like PET bottles, HDPE containers, and PVC pipes into flakes for washing, sorting, and final pelletizing. Their robust wear resistance allows them to handle abrasive materials and occasional contaminants, reliably processing material before requiring maintenance. The ability to produce a consistent flake size is critical for achieving high-quality recycled pellets that can compete with virgin materials.

4.3. Injection Molding and Manufacturing Scrap Recycling

Every injection molding, blow molding, or extrusion operation generates scrap—sprue, runners, rejected parts. On-site granulation is the most cost-effective way to manage this. ShengAo blades are perfectly suited for this task, offering the toughness needed to handle thick, often glass-filled sprues and parts. Their reliable performance ensures a steady supply of clean regrind, maximizing material utilization and improving the overall sustainability of the manufacturing process.

4.4. Film and Bag Recycling

Processing lightweight and flexible materials like PE films and PP woven bags presents a unique challenge, as they can easily wrap around rotating components. ShengAo offers blades with designs suited for this task, such as specific tooth shapes, which grab and cut these materials efficiently without jamming. This capability supports the recycling of agricultural film, silage wrap, and supermarket bags, promoting sustainability in sectors that generate large volumes of flexible plastic waste.

5. Comparative Analysis: ShengAo vs. Other Major Brands

When selecting crusher blades, buyers often compare several brands. The following table provides a simplified comparison based on common market offerings and ShengAo's stated advantages.

| Feature | ShengAo Blades | Typical Competitor A (Generic Brands) | Typical Competitor B (Premium Brands) |

|---|---|---|---|

| Material Quality | High-carbon steel, D2, SKD11 (HRC 58-62) | May use lower-grade steels with inconsistent hardness | May use specialized high-end steels or carbides |

| Customization | High - OEM/ODM supported, flexible on dimensions and angles | Low - Often limited to standard sizes and designs | Varies - Can be high but often at a premium price |

| Price Positioning | Cost-effective, offering a good balance of price and performance | Lower initial cost, but may incur higher long-term costs due to faster wear | Premium pricing, justified for very specific, high-wear applications |

| Key Advantage | Reliability, versatility, and strong customer service for a wide industrial audience | Low initial price | Maximum performance and longevity for specific, demanding tasks |

5.2. Key Differentiators of ShengAo Blades

ShengAo's strategy is not to compete in the "high-precision" niche but to dominate the broad market of industry-universal applications with reliable and affordable products. Their strength lies in providing consistent quality and excellent service rather than exotic materials. The company acts as a partner, offering comprehensive support from material selection to maintenance advice. For the vast majority of recycling and manufacturing operations that process common plastics like ABS, PE, PP, and PET, ShengAo blades represent the most practical and economical choice, delivering the durability needed for continuous operation without the unnecessary cost overhead of ultra-specialized components.

6. Maintenance, After-Sales Support, and Durability

Maximizing the investment in crusher blades involves proper maintenance, reliable support, and understanding the factors that affect durability.

6.1. Routine Maintenance Guidelines

Proper maintenance is straightforward but essential. Key practices include:

- Regular Cleaning: Clean blades after each shift, especially after processing corrosive materials like PVC, using air or a soft brush to prevent rust and residue build-up.

- Edge Inspection and Sharpening: Check blades weekly for dullness or chipping. Blades should be sharpened or replaced when wear exceeds one-third of the edge. ShengAo blades, made from SKD11/D2 steel, typically offer a service life of 300-500 hours before requiring resharpening under normal operating conditions.

- Clearance Adjustment: Maintain a proper gap (typically 0.5-2 mm) between the rotor and stator blades. A gap that is too wide leads to inefficient cutting, while one that is too tight accelerates wear.

6.2. After-Sales Service and Technical Support

ShengAo distinguishes itself with its after-sales service. The company provides a professional service team dedicated to addressing customer issues promptly. This includes offering technical guidance on installation and maintenance, providing sharpening services to restore a blade's performance, and supplying detailed documentation. Their support extends to helping customers select the right blade for their specific material and machine, ensuring optimal performance from the start.

6.3. Durability and Operational Lifespan

The durability of a crusher blade is influenced by the processed material's abrasiveness, machine load, and maintenance. ShengAo blades are engineered for extended service life through the use of wear-resistant materials and robust heat treatment. While not positioned as "high-precision," they are built for long-lasting performance in universal industrial conditions. The goal is to minimize unplanned downtime and reduce the total cost of ownership by offering a product that is both durable to use and easy to maintain, which is a key value proposition for cost-conscious businesses.

7. Conclusion

ShengAo plastic crusher blades represent a smart, practical choice for businesses in the plastic recycling and manufacturing industries. They strike an effective balance between performance, durability, and cost, making them suitable for a wide array of universal applications. By focusing on reliable materials like SKD11 and D2 steel, offering extensive customization options, and backing their products with committed customer support, ShengAo provides a solution that enhances operational efficiency and supports sustainable practices like waste reduction and resource recycling. For companies seeking dependable, industry-universal crusher blades without the high cost of specialized precision components, ShengAo offers a compelling and value-driven proposition.