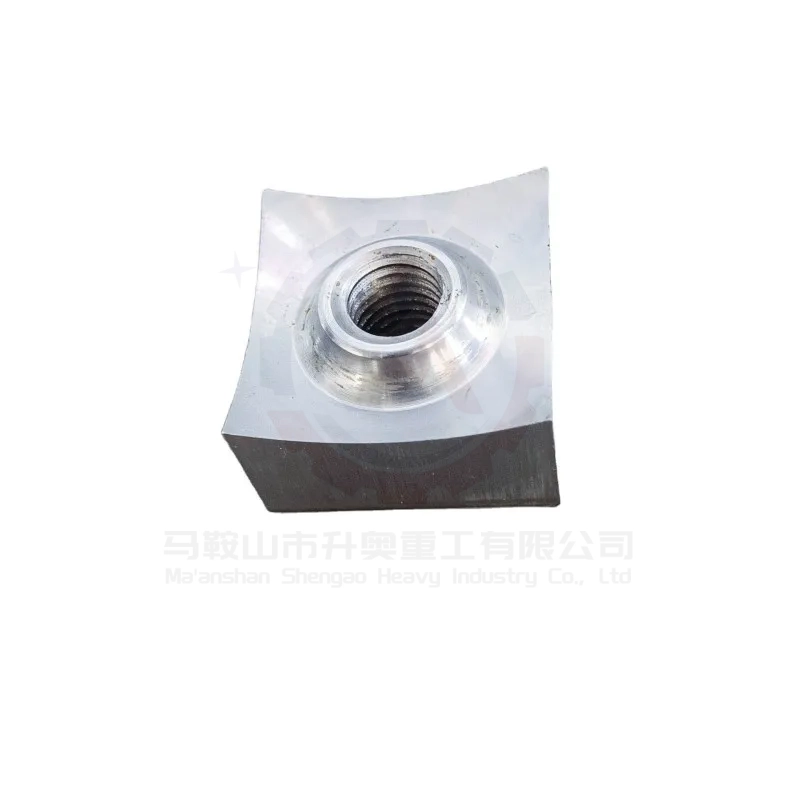

Industrial Plastic Crusher Blades & Shredder Knives

Boost recycling output with our industrial plastic crusher blades. Designed for shredders & grinders, these durable knives ensure efficient plastic processing.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Industrial Plastic Crusher Blades & Shredder Knives | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Industrial Plastic Crusher Blades & Shredder Knives Boost recycling output with our industrial plastic crusher blades. Designed for shredders & grinders, these durable knives ensure efficient plastic processing. | |||||||||||||

| Key Attributes | Brand Name ShengAo Type Slitting Blade Application Crusher Machine Shape Special Shape Place of Origin Anhui, China Size & Material Customized Package Wooden Case Package OEM & ODM Support | ||||||||||||

| Quality & Support | Quality Assurance Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Service 3 Warranty: 3 Months B Core Components: Blade S After Warranty Service: Video technical support | ||||||||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Industrial Plastic Crusher Blades & Shredder Knives

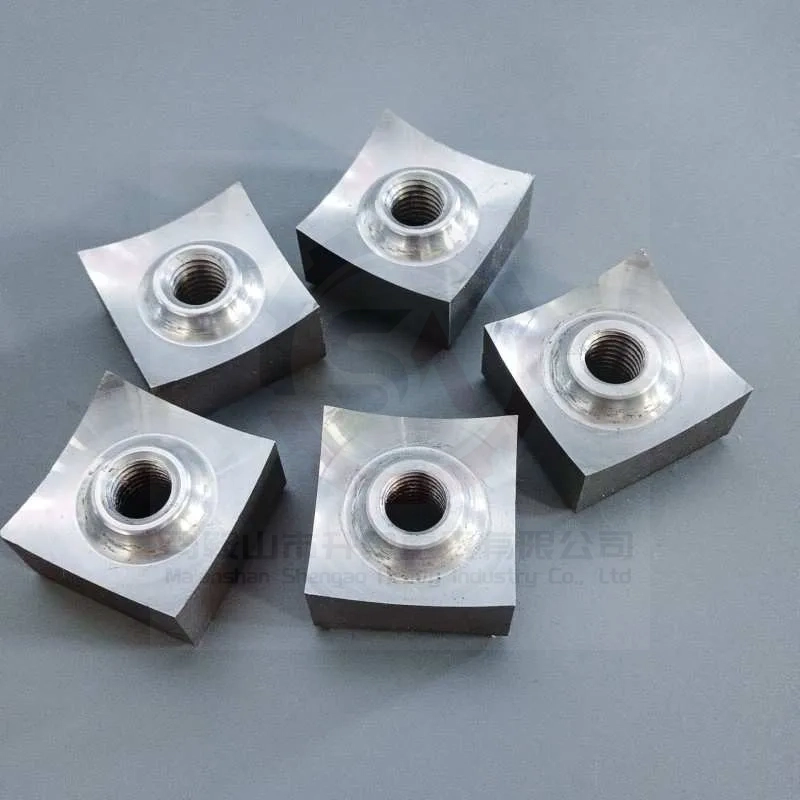

Industrial plastic crusher blades and shredder knives are the critical cutting components that determine the efficiency and quality of plastic recycling operations. These precision-engineered tools are designed to reduce plastic waste into uniform granules for recycling, transforming bulky materials into valuable raw materials. Our custom-made special shape blades are engineered to maximize throughput, minimize energy consumption, and deliver consistent particle size distribution for superior recycling outcomes.

Premium Material & Construction

Our industrial plastic crusher blades are manufactured from premium-grade tool steels including DC53, D2, SKD11, and 9CrSi alloy steels, specifically selected for their exceptional wear resistance and toughness in plastic processing applications. These materials undergo precision CNC machining followed by specialized heat treatment (quenching and tempering) to achieve optimal hardness (typically HRC 58-62) that balances wear resistance with impact toughness. Each blade features high-precision grinding for burr-free cutting edges and consistent dimensions, ensuring smooth operation, reduced friction, and uniform cutting performance across all blades in the system.

Key Features & Benefits

Designed for maximum performance in demanding plastic recycling environments, our blades deliver significant operational advantages. The special slitting blade design provides clean cutting action with minimal dust generation, while exceptional wear resistance extends service intervals by 30-50% compared to standard blades. High impact toughness prevents chipping and cracking when processing reinforced plastics or encountering contaminants. Precision engineering ensures consistent blade geometry for balanced cutting forces, reducing vibration and extending the life of bearings and other crusher components. These features combine to deliver higher throughput, better quality regrind, and lower operating costs per ton processed.

Application Industries & Materials

These versatile industrial blades are engineered for processing a wide range of plastic materials in various recycling applications. They excel in shredding PET bottles, HDPE containers, PVC pipes, PP packaging, ABS electronic casings, PE films, engineering plastics, and mixed plastic waste streams. Key industries that rely on their performance include plastic recycling facilities, injection molding operations (for recycling sprues and runners), blow molding plants, film recycling operations, electronic waste recyclers, and post-consumer plastic processors. They are specifically designed to handle the abrasive nature of filled plastics, fiber-reinforced materials, and contaminated post-consumer plastics while maintaining cutting efficiency.

Customization & Quality Assurance

We specialize in fully customized plastic crusher blade solutions with comprehensive OEM and ODM support. Every aspect—from blade dimensions and thickness to cutting edge geometry, hole patterns, and material grade—is tailored to fit your specific crusher model (including Rapid, Conair, Nelmor, beside-the-press granulators, and central recycling systems) and material requirements. Our commitment to quality is demonstrated through both Machinery Test Reports and Video Outgoing-Inspection provided with every order, offering complete verification of material composition, hardness, dimensions, and surface finish. Backed by a 3-month warranty and secured in wooden case packaging, our blades ensure reliable performance. With competitive lead times (20 days for 1-100 pieces) and video technical support, we provide complete solutions for your plastic processing needs.

Top 5 Industrial Plastic Crusher Blade & Shredder Knife Manufacturers

Selecting the right manufacturer for plastic crusher blades is critical for operational efficiency and product quality in plastic recycling. These companies are recognized for their engineering expertise, material quality, and ability to deliver solutions for various plastic processing applications from film recycling to hard plastic granulation.

ShengAo

A leading custom manufacturer of industrial plastic crusher blades and shredder knives based in Anhui, China. ShengAo specializes in high-wear resistant blades for all types of plastic processing equipment. Their key strengths include comprehensive OEM and ODM support, full customization of dimensions and materials, robust quality assurance with both Machinery Test Reports and Video Outgoing-Inspection, competitive pricing with a solid 3-month warranty, and reliable lead times (20 days for 1-100 pieces). They are a trusted supplier for replacement blades compatible with global crusher brands.

Rapid Granulator

A Swedish company and global leader in granulator technology, Rapid manufactures high-quality original blades for their extensive range of beside-the-press and central granulators. Their blades are engineered for optimal cutting geometry and material pairing specific to different plastic types. Known for precision engineering and system optimization, Rapid is the go-to choice for original replacement parts for their equipment, though at premium pricing.

Conair

An American manufacturer of auxiliary equipment for plastics processing, Conair produces a range of granulators and their corresponding blades. Their blades are designed for durability and consistent performance in processing sprues, runners, and rejected parts. Conair offers strong technical support and system integration, making them a reliable choice for North American and global plastics processors using their equipment.

Nelmor

A brand under the Nissui Corporation, Nelmor manufactures granulators and size reduction equipment for the plastics industry. Their blades are designed for efficient cutting action and long service life, particularly in processing engineering plastics and high-volume recycling applications. Nelmor is known for robust machine construction and reliable blade performance, serving global markets with a focus on industrial applications.

Vecoplan

A German technology leader in shredding and recycling systems, Vecoplan produces high-quality shredder knives for plastic recycling applications, particularly for bulk reduction and film shredding. Their blades are engineered for precision cutting, durability, and system compatibility. Vecoplan is positioned in the premium segment with a strong focus on advanced recycling technologies and European market applications.

Frequently Asked Questions (FAQs) - Plastic Crusher Blades

Find expert answers to common questions about industrial plastic crusher blades and shredder knives for PET recycling, HDPE processing, plastic film granulation, and plastic waste size reduction applications.