Unlock flawless corrugated paper production with the ultimate guide to choosing slitting blades—discover expert tips on blade types, materials.

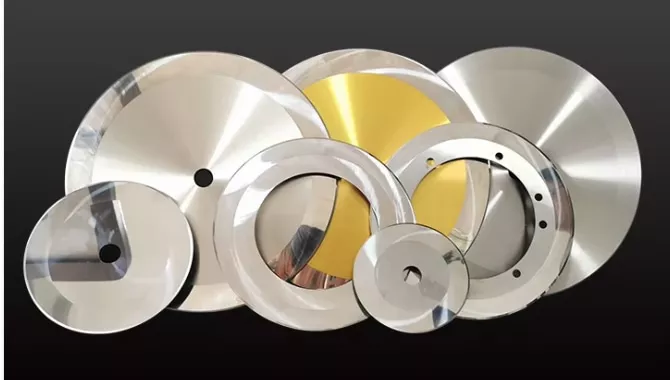

Industrial circular blades deliver exceptional cutting performance across diverse materials and applications. Engineered for precision, durability and operational efficiency, our blades maintain optimal sharpness through demanding production cycles.

At ShengAo, we manufacture custom circular blades to your exact specifications. Custom diameters, thicknesses, bore sizes and tooth configurations are available. Material options include high-carbon steel, alloy steel, stainless steel, and tungsten carbide for specialized applications requiring enhanced wear resistance.

Download our company brochures and product catalogs for detailed information

Comprehensive overview of our company, products, and manufacturing capabilities

Detailed specifications and production capabilities for our industrial blades

Support OEM/ODM services, producing items like slitting knives and cutting blades based on client drawings

Provides comprehensive data on blade specifications and complete dimensional data.

Premium cutting solutions for industrial applications

Maximize your cutting efficiency and productivity with Shengao's high-performance industrial circular blades. Our blades are precision-crafted for superior performance across metalworking, packaging, textiles, and composite material processing. Featuring advanced tooth geometries like Hi/Lo V and Scalloped patterns, along with specialized coatings such as TiN and TiAlN, our blades ensure cleaner cuts, reduced friction, and minimal material buildup for continuous operation. Manufactured from premium materials including Solid Carbide, Carbide-Tipped, and Powder Metallurgy Steels, Shengao blades offer exceptional hardness (HRC 58-95) and wear resistance for extended service life. Available in diameters from 50mm to 1200mm with customizable bore configurations, we provide the perfect cutting solution for slitting, shearing, perforating, and precision slicing applications. Experience the difference with blades designed for high-speed operation, minimal downtime, and unmatched durability in the most demanding industrial environments.

Request Free Blade Consultation

Shengao high-performance circular blades are engineered for precision cutting across diverse sectors. Our Rotary Blades ensure clean, fray-free cuts in textile and leather processing, while Circular Saws deliver smooth, efficient slicing in woodworking and metal fabrication. Slitter Knives excel in handling films, foils, and packaging materials with exceptional accuracy. In food processing, our corrosion-resistant blades provide hygienic, burr-free slicing for meats, cheeses, and vegetables. For paper converting and plastic recycling, Shengao blades offer superior wear resistance, reducing downtime and operational costs. Trust our customized solutions for enhanced productivity in printing, automotive, and advanced material processing applications.

Discover specialized blade types tailored for distinct industrial processing needs

Engineered for continuous slicing operations in high-speed production lines.

Specialized for die-cutting and punch-out operations requiring geometric precision.

Optimized for rotary die cutting systems and continuous web processing.

Heavy-duty cutting solutions for metal, wood, and composite materials.

Find answers to common questions about our industrial circular blades

Shengao circular blades are crafted from premium materials to ensure durability and performance:

Each material undergoes specialized heat treatment to achieve optimal hardness (HRC 58-62) while maintaining toughness.

Selecting the appropriate circular blade depends on several factors:

Our technical team can provide customized recommendations based on your specific requirements and machine specifications.

Proper maintenance extends blade life and ensures optimal performance:

Shengao offers blade sharpening services and provides detailed maintenance guides with every purchase.

Yes, we specialize in custom circular blade manufacturing:

Our engineering team can develop prototypes within 7-10 working days. Minimum order quantities start at just 5 units for custom blades.

Our circular blades serve diverse industrial applications:

We also serve the construction, aerospace, and food processing industries with specialized cutting solutions.