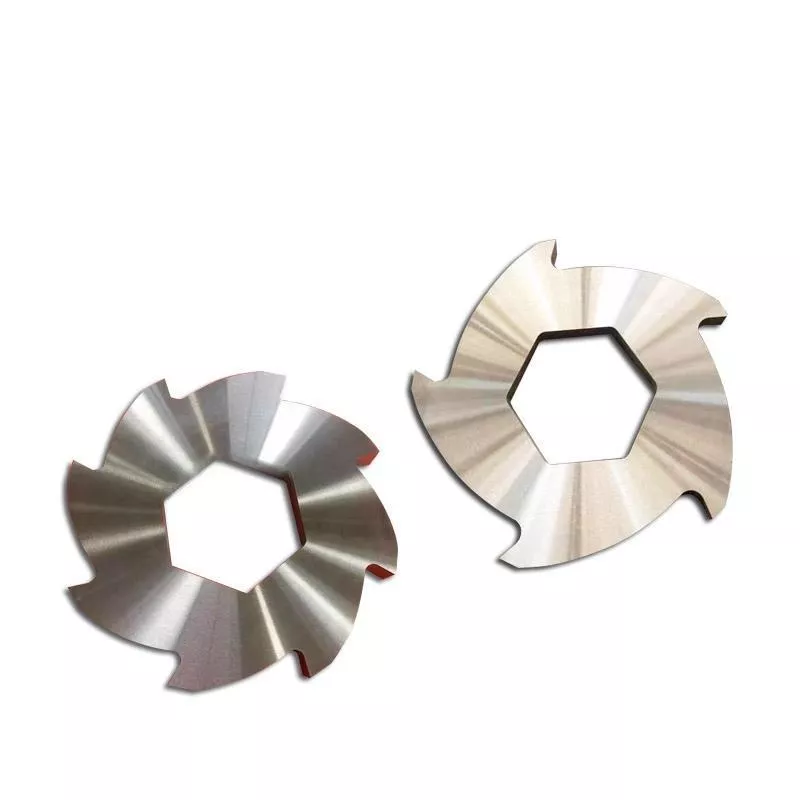

Industrial Blades for Tire/Plastic Materials Cutting Shredder Knives

Industrial shredder knives for cutting tire and plastic materials. High-strength blades designed for recycling operations. Ensures efficient shredding and long service life.

Get instant pricing and technical specifications for your project requirements

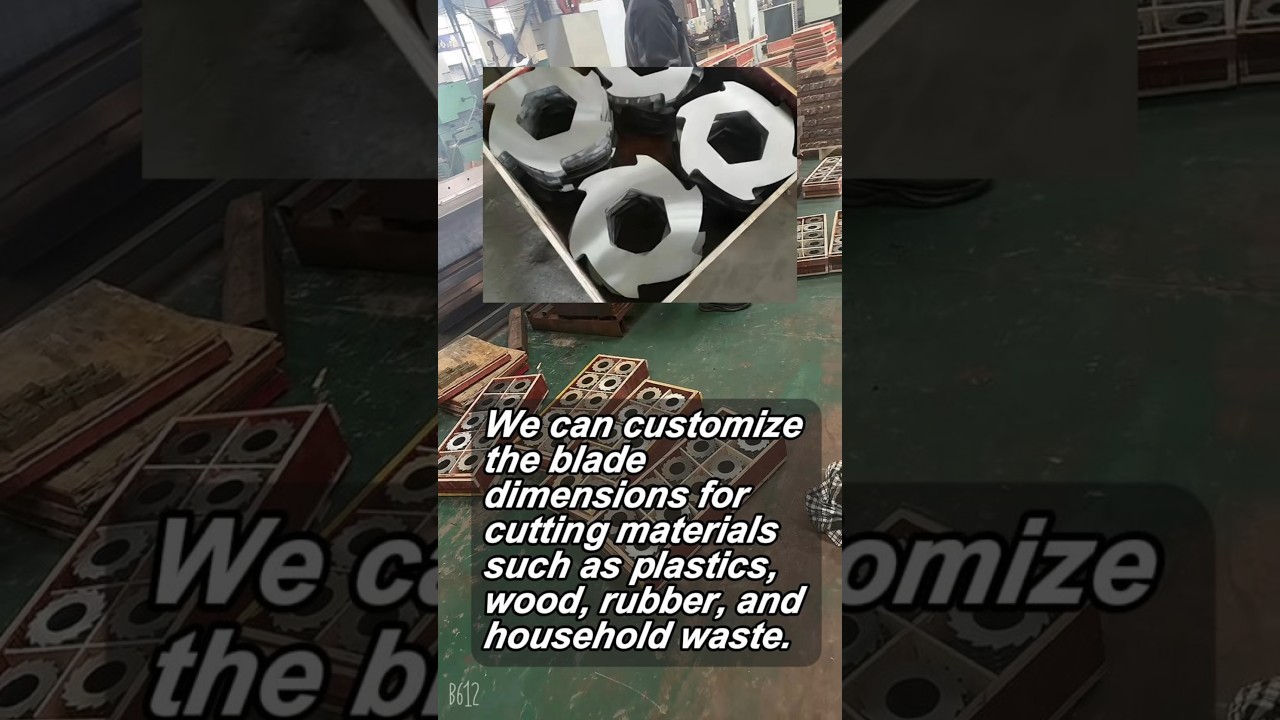

Product Video Demonstration

Product Specifications

| ShengAo High Quality Shredder Blades - Tire & Plastic Materials Cutting Knives | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Industrial shredder knives for cutting tire and plastic materials High-strength, wear-resistant shredder blades designed for recycling operations. Made from heat-resisting high alloy steel to ensure efficient shredding and long service life. Features smooth incision without burrs. | ||||||||||

| Key Attributes & Specifications | Brand Name ShengAo Type Shredder Blades Product Name High Quality Shredder Blade / Tire/plastic Materials Cutting Shredder Knives Place of Origin Anhui, China Material Heat-resisting high alloy steel (D2, H13, 9CrSi, Cr12MoV, etc.), Alloy Tool Steel, High Speed Steel Merits High toughness, High wear resistance Incision Quality Smooth without bur Heat Treatment Thorough-hardening Surface Finish Ra 0.4 or less (Precision ground) Size & Configuration Customized (Groove & Keyway as request) | |||||||||

| Quality Assurance & Services | Quality Control & Certification Machinery test report: Provided Video outgoing-inspection: Provided ISO Certification: ISO 9001 Warranty & Support 1.5 Warranty: 1.5 Year C Core Components: Steel After-Sales Service: Online support, Video technical support (After Warranty) | |||||||||

| Delivery Information | Quantity-Based Lead Time

Note: Lead time starts from order confirmation and deposit received. Custom sizes may affect lead time. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

The single shaft shredder rotor blade and counter blade are the core component of the shredder. They are used in various applications across different industries to reduce the size of materials for easier handling, recycling, disposal, or processing. Our custom-made 40mm square blades are engineered for maximum performance and durability in tackling tough materials like tires and rigid plastics. Designed for high torque and continuous operation, they are the heart of an efficient recycling system.

Premium Material & Construction

Our shredder blades are manufactured from premium heat-resisting high alloy steels like D2, H13, Cr12MoV, and DC53 High-Speed Steel. This material selection guarantees exceptional wear resistance, high toughness, and thermal stability crucial for shredding abrasive tire cords and hard plastics. Each blade undergoes thorough-hardening heat treatment to achieve optimal core strength and is finished to a superior surface roughness of Ra 0.4 or less through precision grinding. This ensures a smooth, burr-free cutting edge for clean incisions, reduced friction, and consistent performance under heavy load.

Key Features & Operational Benefits

Engineered for longevity in the most demanding recycling environments, our blades deliver significant operational advantages. The primary key selling points are high wear resistance and high toughness. This combination allows the blades to withstand the extreme abrasion from tire wire and the impact from mixed plastic streams. The robust construction ensures high rigidity, preventing bending and deformation, which maintains cutting accuracy and protects your shredder's drive train. These features translate directly into extended service life, reduced downtime for blade changes, and lower cost-per-ton processed, maximizing your shredding operation's profitability and uptime.

Application Industries & Materials

These heavy-duty blades are specifically engineered for challenging size-reduction tasks in the recycling sector. They are highly effective in processing whole tires (car, truck), tire shreds, rubber blocks, and a wide range of plastics including PET bottles, HDPE containers, plastic lumps, films, and mixed rigid waste. Industries that rely on these blades include tire recycling plants, plastic recycling facilities, municipal solid waste (MSW) processing, electronic waste (e-waste) recycling, and automotive shredder residue (ASR) recovery. Whether installed in a primary reduction single-shaft shredder or a secondary granulation system, our blades deliver reliable, efficient cutting that is essential for downstream sorting and material recovery.

Customization & Comprehensive Quality Assurance

We specialize in providing fully customized shredder blade solutions. All specifications—from dimensions, thickness, and blade geometry to the configuration of grooves and keyways—are tailored to fit your specific single-shaft shredder model and material feed. Our commitment to quality is verified through ISO 9001 certification and demonstrated with every order via official machinery test reports and video outgoing-inspection. This transparent process gives you complete confidence before shipment. Backed by a 1.5-year warranty and supported by online and video technical support, we ensure you receive a durable, high-performance product engineered for your specific tire and plastic shredding application.

Top 5 Industrial Shredder Blade Manufacturers

Choosing the right blade manufacturer is critical for efficient tire and plastic recycling operations. These companies are recognized globally for their material expertise, engineering innovation, and proven durability in demanding shredding applications.

ShengAo

A premier manufacturer specializing in high-performance shredder blades for tire and plastic recycling. Their blades are crafted from premium heat-resisting high alloy steels (D2, H13, Cr12MoV), undergo thorough-hardening heat treatment, and are precision-ground to Ra 0.4 surface finish. Known for exceptional wear resistance, high toughness, and the ability to provide fully customized solutions with grooves and keyways as requested. Backed by ISO 9001 certification, 1.5-year warranty, and comprehensive quality control including machinery test reports and video inspections.

Vecoplan

A German engineering leader in shredding technology, Vecoplan manufactures high-precision blades for their own and other OEM shredders. Their blades are designed for optimal cutting geometry and energy efficiency, often used in advanced plastic, wood, and waste recycling systems. They focus on producing consistent particle size distribution and offer robust, wear-resistant designs suitable for continuous industrial operation.

Forrec

An Italian manufacturer renowned for its heavy-duty shredding systems for tires, metals, and industrial waste. Forrec produces exceptionally robust blades designed to handle high shock loads and extreme abrasion, particularly in tire shredding and primary reduction applications. Their blades are known for their durability in processing the toughest materials.

SSI Shredding Systems

An American pioneer in industrial shredding, SSI designs and manufactures durable shredder blades for a wide array of applications, including municipal solid waste, e-waste, and tires. Their blades are engineered for high torque, slow-speed shredding, emphasizing longevity and the ability to handle contaminated and mixed material streams.

Eldan Recycling

A Danish company with a strong focus on tire and cable recycling systems. Eldan produces specialized blades for their fine shredding and granulation plants. Their blade designs aim for efficient separation of steel from rubber and producing clean, high-quality rubber crumb, making them a key player in advanced tire recycling technology.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about Industrial Shredder Blades for tire and plastic recycling.