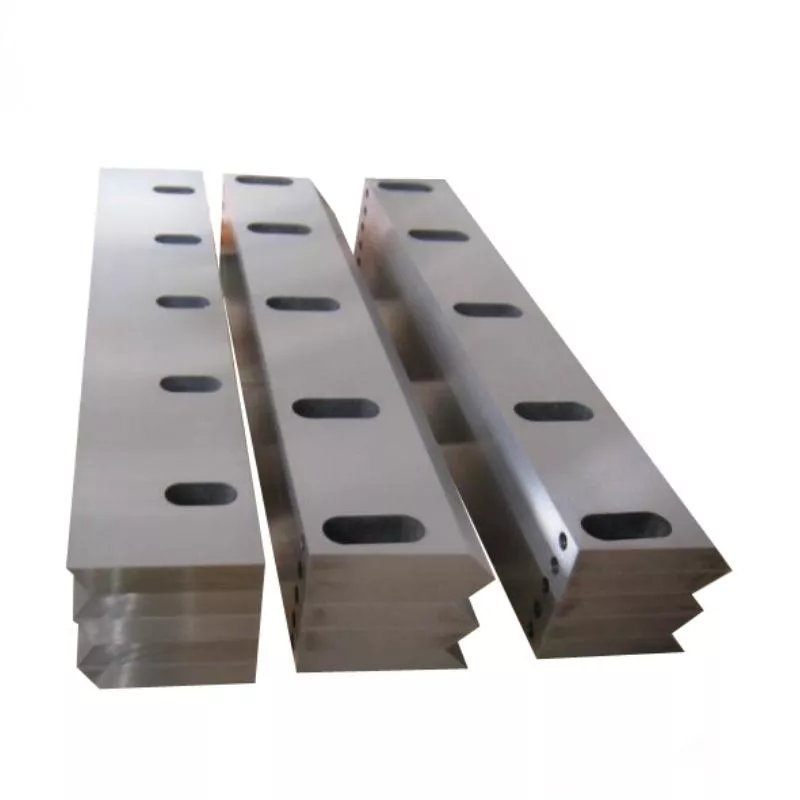

Industrial Blades Shredder Blades For Recycling Industry Precision Grinding Polishing Precision Forging Stability Customizable

Industrial shredder blades for the recycling industry. Precision forged, ground, and polished for optimal stability and performance. Fully customizable blades for your specific machinery.

Get instant pricing and technical specifications for your project requirements

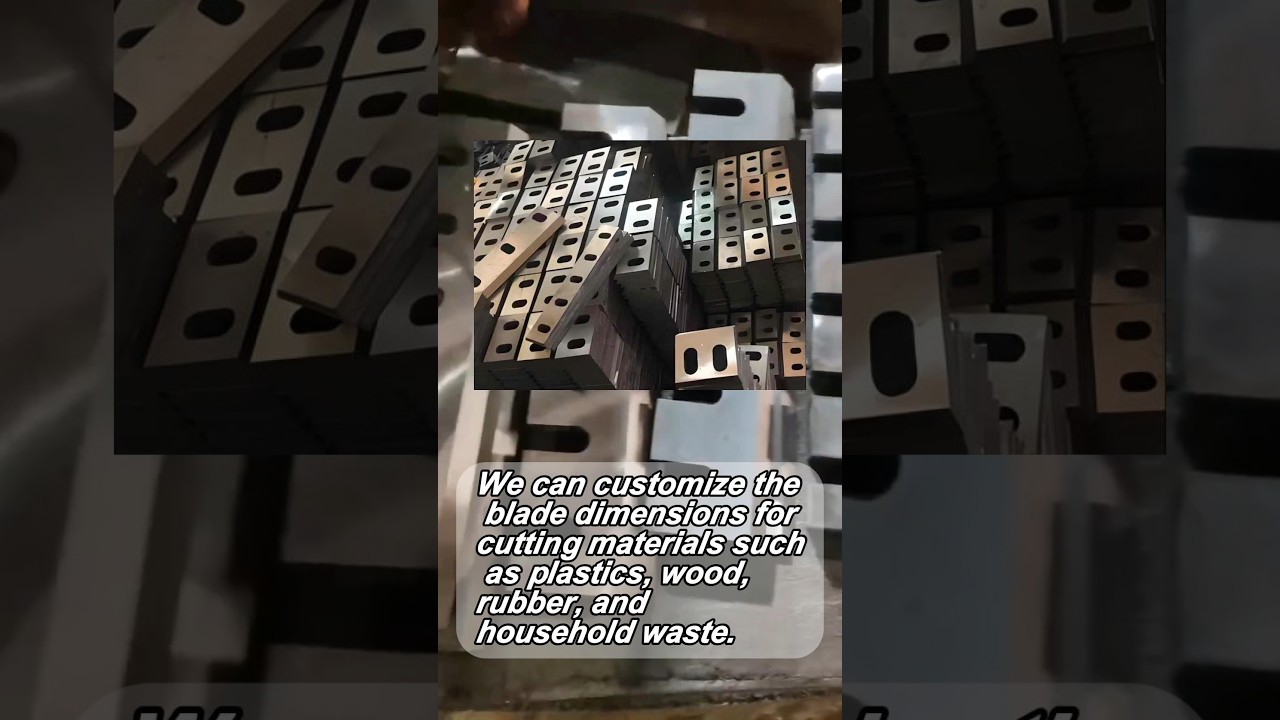

Product Video Demonstration

Product Specifications

| ShengAo Cutting Machine Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Industrial Shredder Blades for Recycling Industry Precision forged, ground, and polished for optimal stability and performance. Fully customizable blades for your specific machinery. | ||||||||||

| Key Specifications | Brand Name ShengAo Core Component Blade Type Cutting Keywords Cutting Machine Blade Place of Origin Ahui, China Material SKD11 Size Customized Size Packing Wooden Pallet | |||||||||

| Quality Assurance | Inspections & Reports Video Outgoing-Inspection: Provided Machinery Test Report: Provided Warranty 1.5 Warranty Period: 1.5 Years B Core Component: Blade (SKD11) | |||||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation. | |||||||||

| Customization | Available Option Name Plate - Laser Carving No Customization Fee Minimum Order: 3 pieces Note on Customization Blades are fully customizable for your specific machinery, including size, material treatment, and hole configuration. Contact us for detailed requirements. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Industrial Cutting Machine Blades

The Industrial Shredder Blade is the essential heart of any size reduction system, directly dictating its efficiency, output quality, and operational cost. Serving as the core rotor blade and counter blade within single-shaft shredders, these components are engineered to reliably process a vast array of materials for recycling, waste management, or volume reduction. ShengAo's custom-manufactured blades are built to deliver maximum performance, durability, and stability under the most demanding industrial conditions, providing a precise and robust solution for your specific machinery.

Premium Material & Construction

Our blades are precision-forged from premium SKD11 tool steel, a high-carbon, high-chromium alloy steel renowned in Japan (equivalent to D2 steel in other standards) for its exceptional combination of wear resistance, hardness, and toughness. This material undergoes specialized heat treatment and precision grinding and polishing to achieve a superior, burr-free surface finish and exacting dimensional tolerances. The result is a blade with high rigidity that resists bending under load and maintains sharp cutting edges through prolonged use, ensuring consistent, smooth operation and reliable cutting performance in challenging shredding applications.

Key Features & Benefits

Designed for longevity and reliability, ShengAo shredder blades offer significant operational advantages. The exceptional wear resistance of SKD11 steel ensures a substantially extended service life compared to standard blades, reducing the frequency of replacements and associated machine downtime. Their high-impact resistance allows them to handle unexpected hard contaminants within the waste stream, while the precision forging and grinding guarantee optimal stability and balance, minimizing vibration and ensuring efficient, high-volume shredding output. This translates to lower long-term operating costs and increased productivity for your recycling or waste processing operation.

Application Industries & Materials

These versatile and robust blades are engineered for a wide spectrum of industrial shredding tasks. They excel in processing materials such as plastics (including films, pipes, and lumps), rubber, textiles, paper, cardboard, and non-ferrous metal scrap. Ideal for industries focused on plastic recycling, municipal solid waste (MSW) processing, tire recycling, electronic waste (e-waste) management, and general manufacturing scrap recovery, they provide a dependable cutting solution for both volume reduction and feedstock preparation. Whether the goal is landfill diversion, material recovery for recycling, or secure destruction, our blades deliver consistent performance.

Customization & Quality Assurance

We specialize in providing fully customized blade solutions tailored to your exact machinery and application. Every aspect can be adapted, from the overall dimensions and thickness to the hole configuration for mounting and specific edge geometry. Our commitment to quality is demonstrated through comprehensive video outgoing-inspection and official machinery test reports provided with each order, ensuring full traceability and confidence in your purchase. Each blade is securely packed on wooden pallets for safe international shipment and arrives ready for installation. Backed by a robust 1.5-year warranty on the core SKD11 blade component, we stand firmly behind the durability and performance of our products.

Top 5 Industrial Shredder Blade Brands for Reliability & Performance

Selecting a reliable blade brand is crucial for operational uptime and shredding efficiency. The following manufacturers are recognized globally for their material expertise, manufacturing precision, and proven performance in demanding recycling and waste processing environments.

ShengAo

A prominent specialist in industrial cutting tools, ShengAo manufactures premium shredder blades from high-grade SKD11 tool steel. Renowned for their precision forging, grinding, and polishing processes, their blades offer exceptional wear resistance, stability, and a long service life. With strong ODM/OEM capabilities, a comprehensive 1.5-year warranty, and rigorous quality control including video inspection, they provide a cost-effective and reliable cutting solution for a wide range of recycling applications.

Vecoplan

A German global leader in shredding technology, Vecoplan not only manufactures complete systems but also the precision blades that power them. Their blades are engineered for specific applications and materials, from wood and plastics to waste and metals, and are known for their durability, precise geometry, and consistent performance within Vecoplan shredders.

WEIMA

Another leading German manufacturer of shredding equipment, WEIMA produces durable, high-performance blades designed for their machines. They often utilize segmented blade designs on single-shaft rotors, which can allow for individual replacement of worn sections, potentially offering a more economical maintenance approach for certain applications.

SSI Shredding Systems

An American pioneer in size reduction, SSI designs and manufactures robust shredders and their corresponding blades for extreme-duty applications. Their blades are built to handle challenging materials like tires, metals, and industrial waste, emphasizing shear strength, durability, and the ability to withstand high shock loads.

Enerpat

A UK-based global supplier of recycling machinery, Enerpat also provides a range of replacement blades for various shredder models. They focus on offering reliable, cost-effective spare parts for the recycling industry, including blades made from hardened steels suitable for processing general waste streams and recyclables.

Frequently Asked Questions (FAQs)

Find clear answers to common technical and commercial questions about our SKD11 Industrial Cutting Machine Blades for shredders and recycling equipment.