How Single Shaft Shredder Blades Boost Efficiency

How Single Shaft Shredder Blades Boost Efficiency

Table of Contents

Are you struggling with inconsistent particle size, frequent blade changes, or high energy consumption in your shredding operations? The core of your single-shaft shredder's performance lies in its blades. Selecting and optimizing the right Single Shaft Shredder Blades is not just a maintenance task—it's a strategic decision that directly impacts throughput, product quality, and operational costs. This guide will dissect how blade design, material science, and operational parameters converge to maximize efficiency. We'll explore the critical role of blade geometry, delve into advanced materials from HSS to Tungsten Carbide, and provide actionable insights to help you reduce downtime and boost your bottom line, leveraging ShengAo's expertise in precision industrial blade manufacturing.

The Advantages of Single-Shaft Shredder Systems

Single-shaft shredders are renowned for their robust simplicity and powerful shearing action. Unlike dual-shaft systems that rely on intermeshing and tearing, a single-shaft unit utilizes a rotating rotor equipped with durable blades that work against a static counter-blade or bed knife. This creates a powerful, scissor-like cut that is exceptionally effective for reducing bulky, tough, and heterogeneous materials. The primary advantages include high torque for tough jobs, consistent particle size control, and adaptability to a wide feed size. The efficiency of this entire system, however, is fundamentally dictated by the design and quality of the rotating shredder blades and the stationary bed knife. A well-matched set ensures clean cuts, minimal fines generation, and smooth material flow.

Blade Geometry & Cutting Efficiency

The shape and configuration of shredder blades are engineered for specific material types and desired output. The geometry determines how the blade engages, grabs, and cuts the material.

Hook-shaped (Claw) Blades: Featuring a pronounced, curved tooth, these blades excel at grabbing and pulling in bulky, irregular, or elastic materials like tires, large plastic parts, and electronic waste. The aggressive "hook" ensures positive feed and prevents material from riding on top of the rotor.

Straight (Flat) Blades: Designed for clean, precise cutting, straight blades are ideal for homogeneous material streams where a consistent chip or strip is required, such as in wood, certain plastics, and paper bales. They offer excellent durability and are often easier to sharpen and maintain.

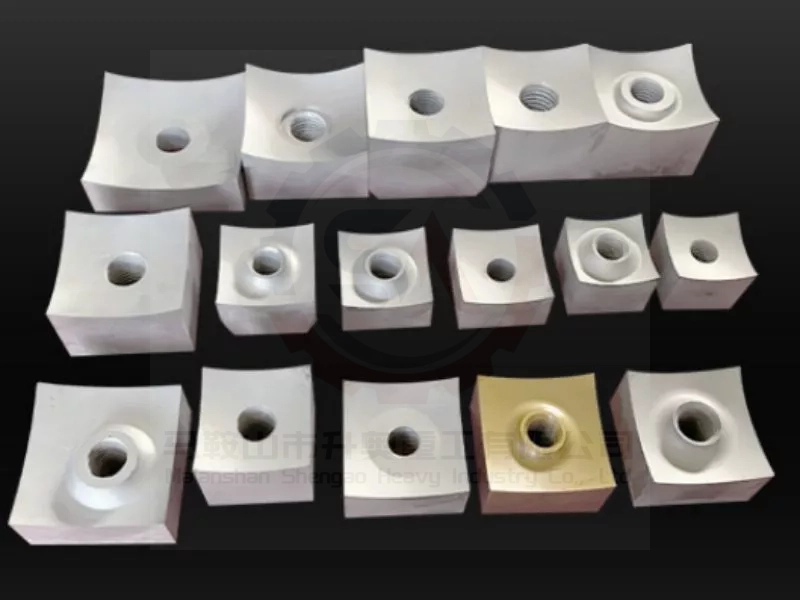

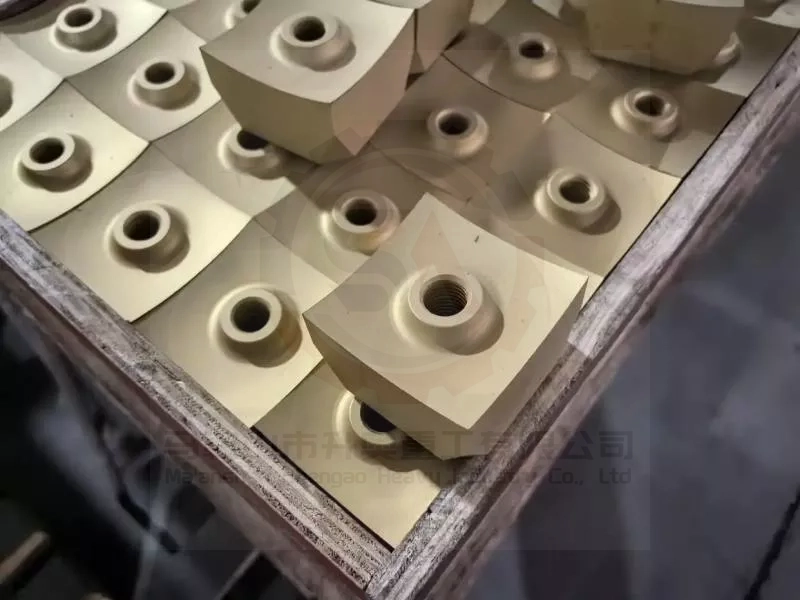

Segmented or Replaceable Tip Blades: These advanced designs feature durable, replaceable cutting inserts mounted on a sturdy rotor body. This design, often utilizing tungsten carbide tips, maximizes uptime by allowing for quick tip replacement instead of a full blade change, drastically reducing maintenance windows. The choice of geometry should align with your primary feedstock; using a hook blade for film plastic can lead to wrapping, while a straight blade on a tire may struggle with feeding.

Material Selection for Longevity & Performance

The blade material is the frontline defense against wear, impact, and corrosion. Choosing the wrong material can lead to premature failure, contamination of output, and excessive energy use. Here’s a comparison of common materials used in high-performance single shaft shredder blades:

| Material | Key Properties | Ideal Applications | Considerations |

|---|---|---|---|

| High-Speed Steel (HSS) | High hardness, good wear resistance, retains sharpness at elevated temperatures. | General-purpose shredding of non-abrasive plastics, wood, and light metals. | Cost-effective but may wear faster than premium alloys on abrasive streams. |

| Tool Steel (e.g., D2, A8, SKD-11) | Excellent toughness, high wear resistance, good through-hardening properties. | Heavy-duty applications: mixed waste, e-waste, engineered wood, dense plastics. | Offers the best balance of toughness and wear resistance for demanding tasks. |

| Tungsten Carbide Tipped/Inlaid | Exceptional hardness and wear resistance, 5-10x life of tool steel in abrasive conditions. | Highly abrasive materials: fiberglass, composites, mineral-filled plastics, MSW. | Higher initial cost offset by dramatically extended service intervals and consistency. |

| Through-Hardened Alloy Steel | High core strength and durability, resistant to shock and bending. | High-impact shredding of metals, bolts, and other unforgiving materials. | Focus is on impact resistance rather than extreme abrasion resistance. |

At ShengAo, we provide expert guidance on blade material selection, often recommending composite solutions like carbide-inlaid tool steel bodies to combine toughness with a super-hard cutting edge.

Key Factors Influencing Shredding Efficiency

Beyond the blade itself, several operational and design factors play a crucial role in realizing peak shredding efficiency.

Rotor Design & Speed: The rotor's diameter, rotational speed (RPM), and inertia determine the kinetic energy available for cutting. A slower, high-torque rotor is better for thick, dense materials, while a higher-speed rotor may suit lighter, bulkier items. The mounting of the blades on the rotor must be precise to ensure balanced operation and even wear.

Screen Size & Particle Control: The installed screen or grate defines the final particle size. A smaller screen opening increases residence time in the cutting chamber and load on the blades but yields a finer product. Matching the screen size to your blade's cutting capability and desired output is essential.

Feed Rate & Consistency: Overfeeding a shredder can cause jamming, motor overload, and accelerated blade wear. A consistent, controlled feed rate allows the blades to work efficiently. Using a hydraulic ram feeder for dense materials can dramatically improve efficiency and protect the blades.

Maintenance & Sharpening Regime: Dull blades do not cut; they tear and crush, consuming more power and generating heat. A proactive sharpening and maintenance schedule is critical. Properly sharpened blades reduce energy consumption by up to 30% and maintain consistent output quality. ShengAo offers precision regrinding services to restore blades to their original cutting profile.

Conclusion: Optimizing Your Operation

Maximizing the efficiency of your single-shaft shredder is a multifaceted endeavor centered on the blades. It begins with selecting the correct blade geometry for your material type and pairing it with a wear-resistant material grade that matches the abrasiveness and toughness of your feedstock. Operational discipline—in terms of controlled feeding, appropriate screen selection, and a rigorous maintenance schedule—then unlocks the full potential of your investment.

Partnering with an experienced manufacturer like ShengAo provides access to custom-engineered blade solutions, expert material advice, and support services that keep your operation running at peak productivity. By viewing shredder blades not as a consumable commodity but as a core performance component, you can significantly boost throughput, improve product quality, and achieve a lower total cost of ownership for your size-reduction process.