How to Achieve Perfect Cuts with Circular Slitting Blades

How to Achieve Perfect Cuts with Circular Slitting Blades

Table of Contents

What defines a "perfect cut" in industrial slitting, and how can you consistently achieve it across diverse materials like metal, plastic, paper, and textiles? This expert guide provides the definitive answers, delivering actionable insights into the precise selection, optimization, and care of circular slitting blades that are critical for quality and efficiency. We will break down the four pillars of perfect cutting: strategic blade selection, edge radius optimization, the transformative benefit of a mirror finish, and a disciplined maintenance regimen. By mastering these elements, you can eliminate burrs, reduce material waste, extend blade life, and ensure flawless, high-speed production, turning cutting operations from a cost center into a competitive edge.

The Foundation of Perfection: Precision, Consistency, and Clean Edges

A perfect cut is not a subjective measure; it's a quantifiable outcome characterized by a flawless edge, absolute dimensional accuracy, and zero deformation of the material. Achieving this consistently hinges on the foundational synergy between blade precision and process control. High-quality circular slitting blades act as the ultimate point of contact, where micron-level tolerances in grinding directly translate to the quality of the slit. The primary goal is to apply clean, concentrated shear force without generating excessive heat or lateral stress, which causes burrs, feathering on textiles, or delamination in composites.

This requires blades that are perfectly balanced, with uniform hardness and a geometry engineered for the specific material's ductility and thickness. Consistency in output—whether slitting thousands of meters of film or precision-notching metal coils—depends on the blade's ability to maintain its initial sharpness and profile. Therefore, the pursuit of perfect cuts begins long before the blade spins; it starts with engineering and selecting the right tool for the fundamental physics of the cut, ensuring every slice is a mirror of the first.

Material Mastery: Optimizing Blades for Metal, Plastic, Paper, and Textiles

The concept of a "universal" blade for perfect cuts is a myth. Each material family presents unique challenges—from the work-hardening tendency of stainless steel to the melting point of plastics and the fibrous nature of textiles. Tailoring the blade's material, coating, and edge geometry is non-negotiable for perfect results. The following table outlines a targeted approach for key industries.

| Material Type | Primary Cutting Challenge | Recommended Blade Material & Treatment | Key Geometry & Finish for a Perfect Cut |

|---|---|---|---|

| Metals (Steel, Copper, Aluminum) | Burr formation, work hardening, heat generation, edge rollover. | Premium High-Speed Steel (HSS), Powder Metallurgy Steel; TiN or TiCN coatings. | Precision-honed edge radius to control shear angle; polished flank to reduce friction. |

| Plastics & Films (PET, PP, PVC) | Melting, stringing, polymer buildup, unclean separation. | Solid Tungsten Carbide or HSS with specialized polish. | Razor-sharp edge with minimal radius; mirror finish on sides to prevent material adhesion. |

| Paper & Cardboard | Dust, edge tear, fiber pull, rapid dulling from abrasives. | Wear-resistant HSS or Carbide-Tipped blades. | Optimized shear angle; sometimes micro-serrated edges for multi-ply board to prevent slipping. |

| Textiles & Nonwovens | Fraying, edge fusion (synthetics), fabric distortion. | Corrosion-resistant HSS or hardened stainless steel. | Extremely sharp, sometimes laser-sharpened edge; specific bevel angles for clean fiber severance. |

| Composite Materials | Extreme abrasiveness, delamination, uneven fiber/matrix cutting. | Premium Tungsten Carbide with diamond-like carbon (DLC) coatings. | Reinforced edge geometry; ultra-smooth finish to minimize resin drag and heat. |

For a comprehensive look at material properties, visit our blade materials classification guide.

Critical Optimization Factors: Edge Radius, Mirror Finish, and Maintenance

Selecting the correct blade material is only the first step. Three operational factors profoundly influence the quest for perfect cuts: edge radius, surface finish, and proactive maintenance. The edge radius (or sharpness) is a critical design parameter. A larger, honed radius provides strength for cutting harder materials like metals, preventing chipping and controlling the point of fracture. Conversely, plastics and films demand a near-zero-radius, "razor" edge for a clean, melt-free shear. An incorrect radius is a primary cause of burrs and premature wear.

Secondly, a mirror-finish polish on the blade's sides and cutting facets is not merely cosmetic. This ultra-smooth surface drastically reduces friction and adhesion, preventing material buildup (especially critical with sticky films or molten plastics), lowering operating temperatures, and ensuring the material releases cleanly from the blade. Finally, a disciplined maintenance and inspection routine is essential. This includes regular cleaning to remove residue, tracking cut mileage, and monitoring for the earliest signs of edge degradation—such as increased cutting force or subtle quality changes—before defective product is produced. Partnering with a specialized circular blade manufacturer like ShengAo ensures you get expert guidance on these fine-tuning parameters, which are often the difference between good and perfect results.

The ShengAo Precision Advantage: Engineering Your Perfect Cut

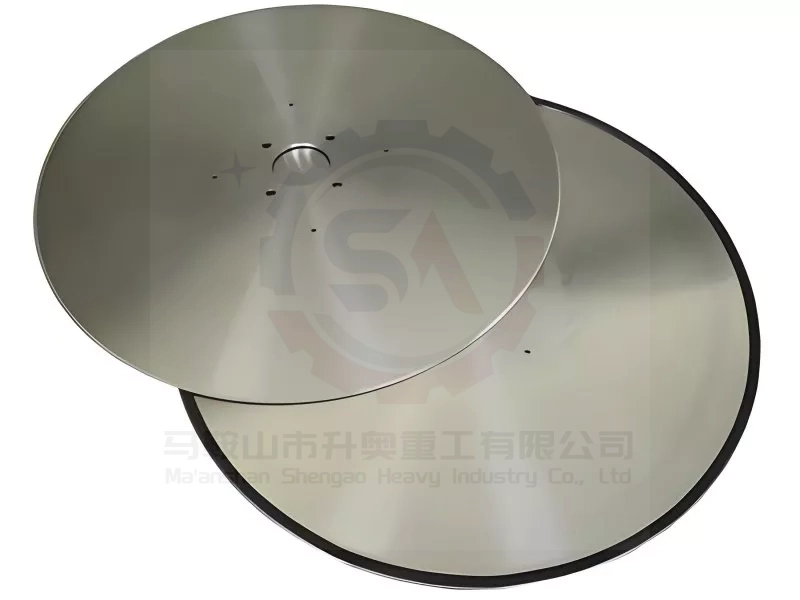

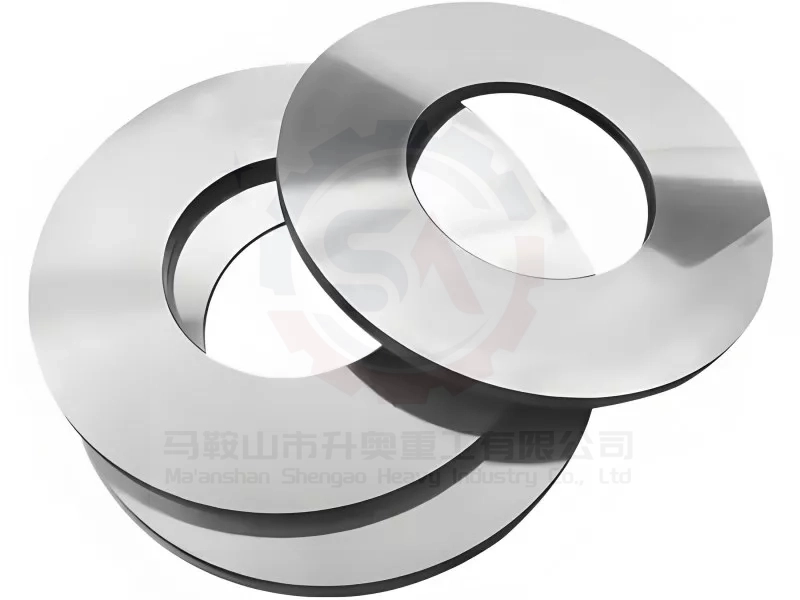

At ShengAo, we engineer Circular Slitting Blades to deliver the elusive "perfect cut" for your specific application. We move beyond standard offerings by first analyzing your material composition, thickness, line speed, and desired edge quality. Our engineers then specify the optimal substrate—from high-purity tungsten carbide to advanced high-speed steels—and apply proprietary grinding techniques to create the exact edge geometry and radius your material demands.

Our commitment to perfection is embodied in our proprietary mirror-finishing process, which minimizes friction and buildup, and our rigorous quality control that ensures every blade meets micron-level tolerances. The result is a blade that doesn't just fit your machine, but is precisely calibrated for your process—delivering longer intervals between sharpening, consistent quality from the first to the millionth cut, and a significant reduction in material waste and downtime. Don't let imperfect cuts limit your productivity and profit. Contact the ShengAo engineering team today to discuss how our application-optimized slitting blade solutions can become the foundation of your perfect cutting process.