The High Temperature Forging Garden Shredder Blade/crusher Blade/knife Plastic Wood Shredder Blade Strong Crusher Blade

High-temperature forged garden and wood shredder blades. Exceptionally strong crusher knives for processing plastic, wood, and organic waste. Built for impact resistance and long-term reliability.

Get instant pricing and technical specifications for your project requirements

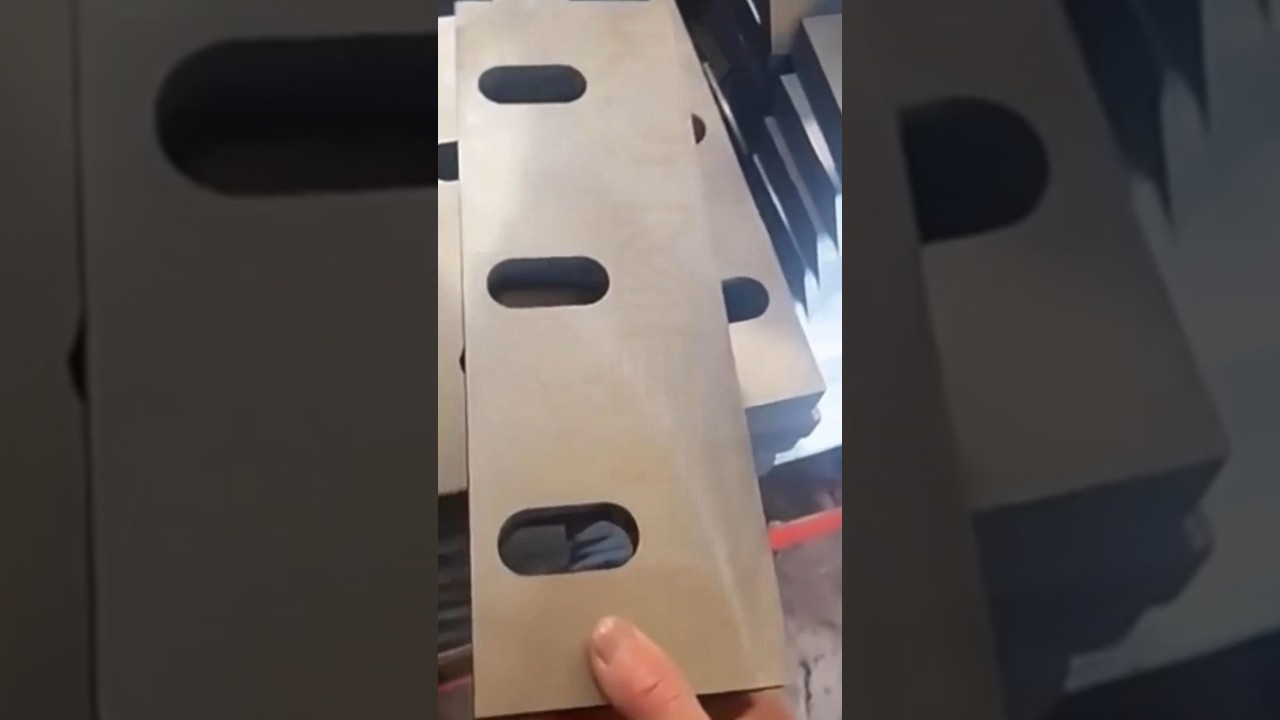

Product Video Demonstration

Product Specifications

| ShengAo High-Temperature Forging Garden Shredder Blade/Crusher Blade | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

High Temperature Forging Garden Shredder Blade/Crusher Blade/Knife Plastic Wood Shredder Blade Strong Crusher Blade High-temperature forged garden and wood shredder blades. Exceptionally strong crusher knives for processing plastic, wood, and organic waste. Built for impact resistance and long-term reliability. | ||||||||||

| Key Attributes | Material Metal Spare Parts Type Blade Weight (KG) 2 Hardness HRC 56-58 Place of Origin Anhui, China Application Crushing and Shredding Surface Treatment Rust Proofing Treatment Packing Wooden Case Size Customized Size | |||||||||

| Quality & Warranty | Quality Assurance Video outgoing-inspection: Provided Machinery test report: Not Available Warranty 3 Warranty Period: 3 Months | |||||||||

| Key Selling Points | Long Service Life Easy To Operate | |||||||||

| Delivery Lead Time |

Lead time starts from order confirmation and deposit received. | |||||||||

| Customization Options |

Note: Other customization options available upon request. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our High-Temperature Forging Garden & Wood Shredder Blades

The robust blade is the absolute heart of any reliable garden or wood shredder, directly responsible for its ability to efficiently process organic and light industrial waste. Designed for the demanding task of reducing branches, leaves, plastic, and wood for composting, recycling, or volume reduction, ShengAo's high-temperature forged crusher blades are engineered to deliver maximum durability, impact resistance, and long-term reliability in continuous operation, transforming tough materials into manageable mulch or biomass.

Premium Material & Construction

Our blades are manufactured using specialized high-temperature forging processes applied to high-quality metal alloys. This forging technique significantly enhances the internal grain structure of the metal, resulting in superior toughness and fatigue resistance compared to standard casting or machining. Each blade is hardened to a robust HRC 56-58, providing an optimal balance between a hard, wear-resistant cutting edge and a tough, shock-absorbing body. A final rust-proofing surface treatment is applied to ensure longevity even when processing moist garden waste, and every blade features a precision-ground cutting edge for clean, efficient cuts.

Key Features & Benefits

ShengAo garden shredder blades are built to withstand the rigors of daily use. The primary benefit is exceptional impact resistance and strength, allowing them to handle unexpected stones, nails, or hard knots in wood without chipping or breaking. Their long service life drastically reduces the frequency and cost of replacement parts. Weighing approximately 2 kg, they are designed for effective cutting momentum while remaining manageable. The design prioritizes being easy to operate and install, minimizing machine downtime and simplifying maintenance for users, from landscaping professionals to dedicated gardeners.

Application Industries & Materials

These versatile and tough blades are perfect for a wide range of light industrial and landscaping size-reduction tasks. They excel in processing garden and yard waste such as tree branches, shrubs, leaves, and hedge trimmings. They are also highly effective for shredding wood pallets, demolition lumber, plastic containers, and other composite organic materials. Ideal for landscaping companies, municipal park maintenance, composting facilities, biomass fuel producers, and DIY woodworking shops, they provide a reliable cutting solution for turning waste into valuable resources like mulch, compost feedstock, or wood chips.

Customization & Quality Assurance

We specialize in providing fully customized blade solutions to perfectly fit your specific garden shredder or crusher model, whether it's a Bosch, Makita, Patriot, or other brand. Every aspect, from dimensions and mounting hole patterns to the cutting edge profile, can be tailored. For branding, we offer logo or graphic laser printing with a minimum order of 10 sets. Our commitment to quality is demonstrated through a comprehensive video outgoing-inspection provided with each order. While a machinery test report is not standard for this product line, our stringent forging and hardening processes, coupled with a 3-month warranty, ensure you receive a robust and reliable product, securely packed in wooden cases.

Top 5 Garden & Wood Crusher Blade Brands for Durability

For consistent chipping and shredding performance, the quality of the crusher blade is paramount. These brands are recognized for their material strength, design, and reliability in handling demanding organic and light industrial waste processing.

ShengAo

A specialist in durable cutting tools, ShengAo manufactures high-temperature forged garden shredder blades known for exceptional impact resistance (HRC 56-58). Their process enhances metal toughness, making blades ideal for processing branches, wood, and mixed garden waste. With fast 15-day lead times for up to 100 sets, a 3-month warranty, video inspection, and customization options including laser branding, they offer a robust and practical solution for professional landscaping and composting operations.

Bosch (Garden Tools Division)

The global power tool giant produces a range of high-quality replacement blades for their own line of garden shredders. Known for precision engineering and reliable performance, Bosch blades are designed to match their machines perfectly, offering good durability for typical garden waste processing.

Makita

Another leading power tool manufacturer, Makita offers durable replacement cutting blades and hammers for their garden shredders. Their blades are built to withstand rigorous use and are part of a system designed for efficient garden waste reduction, appealing to both professionals and serious DIY enthusiasts.

Tazz

A brand specializing in outdoor power equipment for serious homeowners and landscapers, Tazz offers robust chipper shredders with correspondingly durable blades. Their machines and blades are designed to handle tougher jobs, like processing small branches and dense yard waste, with an emphasis on power and reliability.

Sun Joe (Snow Joe)

A popular brand for electric and corded outdoor power tools, Sun Joe provides affordable and accessible garden shredders. Their replacement blades offer a cost-effective solution for maintaining their machines, suitable for general garden cleanup tasks for the average homeowner.

Frequently Asked Questions (FAQs)

Find clear answers to common questions about our High-Temperature Forging Garden Shredder Blades for efficient wood and waste processing.