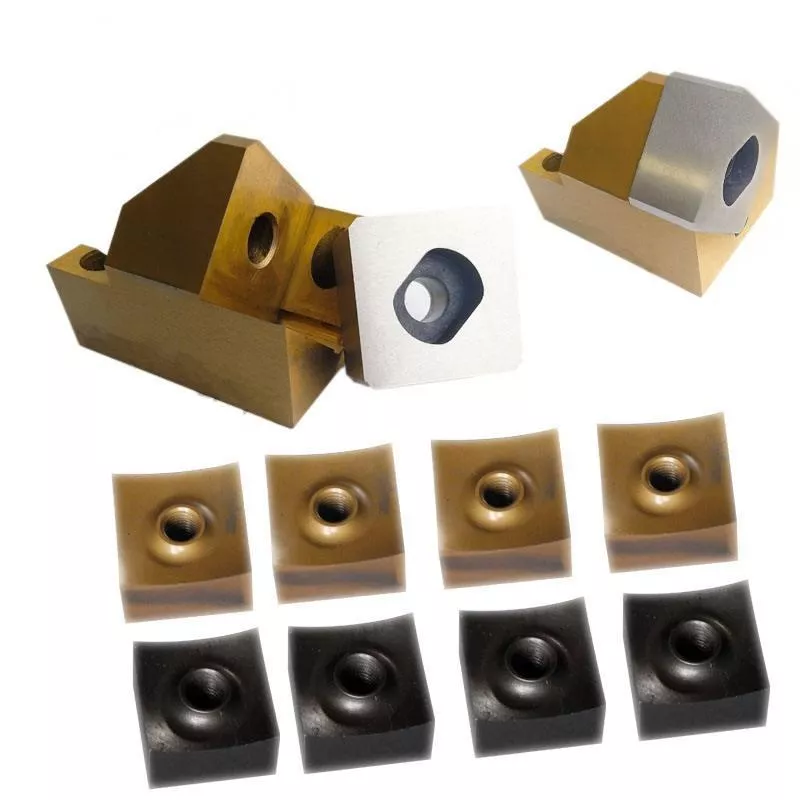

High Quality Single-shaft Shredder System Rotary Blades/Single Shaft Shredder Knives Square Rotor Crusher Knives

High-quality rotary blades/crusher knives for single-shaft shredder systems. Our square rotor knives ensure optimal performance and reliability in demanding recycling operations.

Get instant pricing and technical specifications for your project requirements

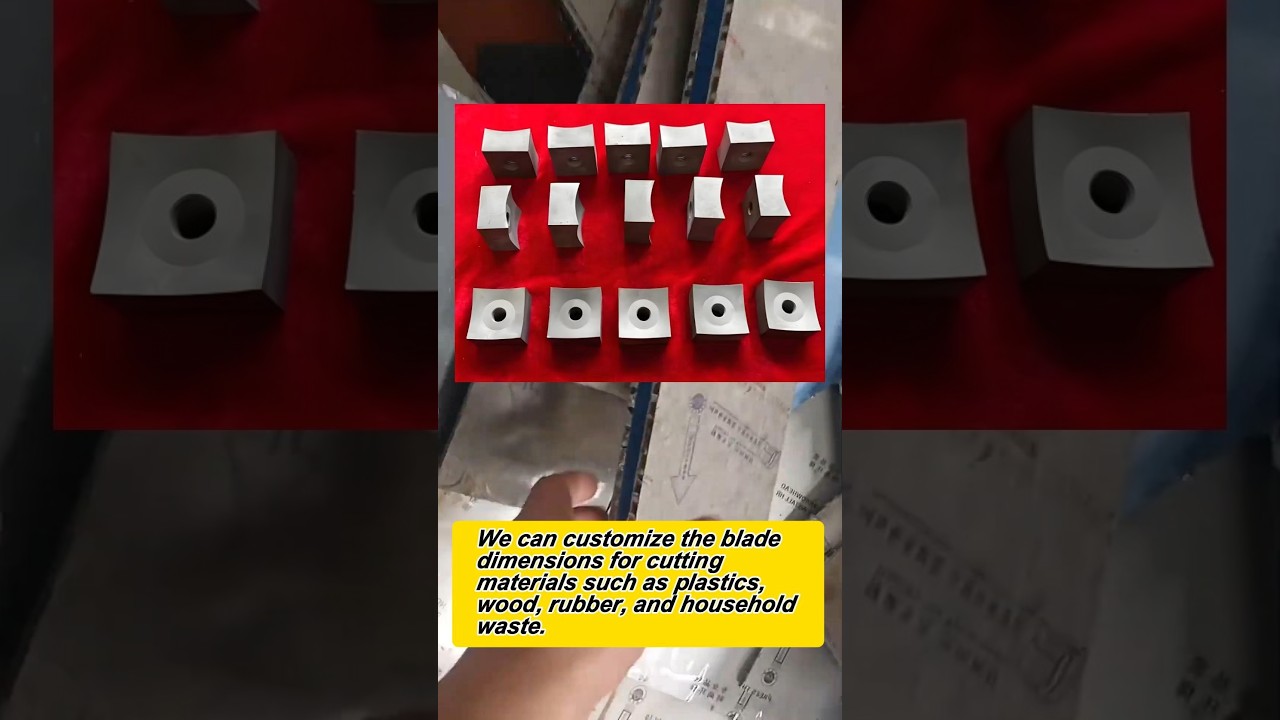

Product Video Demonstration

Product Specifications

| ShengAo Shredder Blades - High Quality Single-shaft Shredder System Rotary Knives | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

High Quality Single-shaft Shredder System Rotary Blades / Square Rotor Crusher Knives High-quality rotary blades/crusher knives for single-shaft shredder systems. Our square rotor knives ensure optimal performance and reliability in demanding recycling and industrial process operations. | |||||||||||||

| Product Specifications | Brand Name ShengAo Product Name Shredder Blade Application Industrial Process Usage Shape Customers' Drawings Package Wooden Case Key Advantage Improved Efficiency Size Customized Size Hardness HRC 56-65 Merits High Toughness MOQ 10 pcs Tolerance Specification Exceed OEM Specification | ||||||||||||

| Quality Assurance | Quality Control Provided Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 1.5 Warranty Period: 1.5 Year C Core Components Covered: Gearbox, Pressure Vessel, Engine, Motor | ||||||||||||

| Lead Time | Quantity-Based Production Lead Time

Lead time starts from order confirmation and deposit received. | ||||||||||||

| Customization Options | Customization services are available for bulk orders. Please contact our sales team for detailed requirements and feasibility.

Note on Customization: All customizations (Logo, Packaging, Graphics) are handled "As requested". Please share your detailed specifications for a precise quote. | ||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

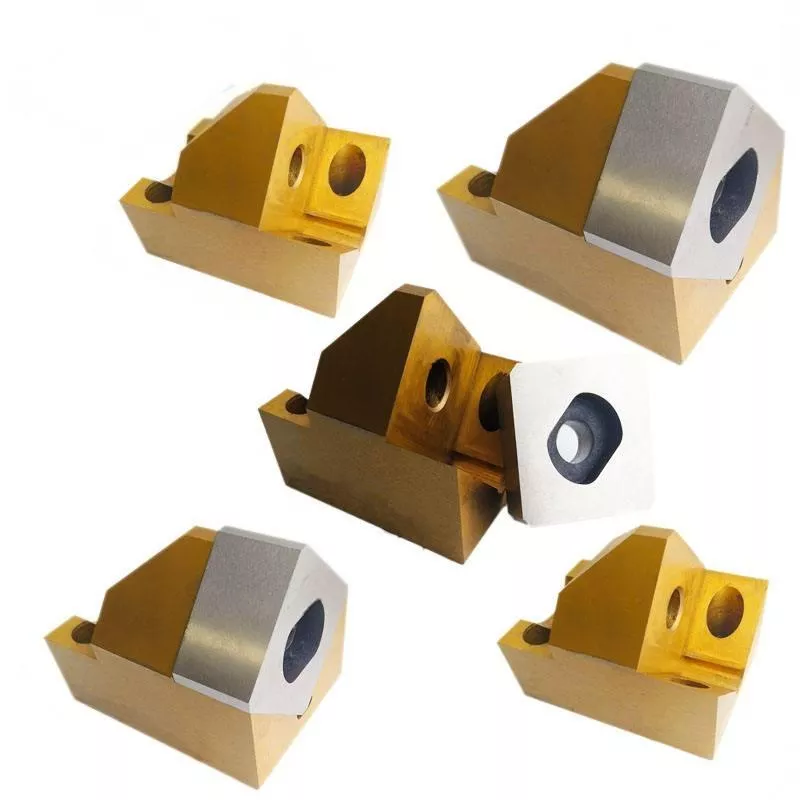

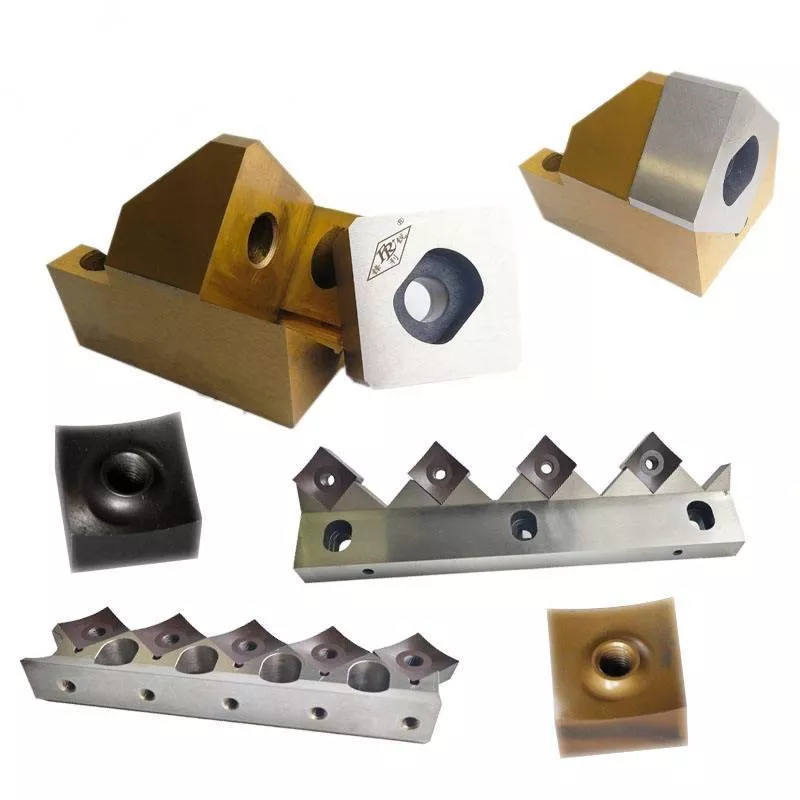

The single shaft shredder rotor blade and counter blade are the core component of the shredder, responsible for the efficient size reduction of various materials in industrial applications. These blades are engineered to work with a sizing screen that ensures shredded material meets precise size requirements, making them ideal for recycling operations and waste management processes.

Our custom-made blades, including common sizes such as 60x60x30 mm and 40x40x25 mm with R-shaped cutting edges, are designed for optimal performance in demanding environments across different industries. The square-shaped design with curved edges and center mounting hole ensures secure installation and effective cutting action when working in conjunction with stationary blades on the shredder.

Premium Material & Construction

Our shredder blades are manufactured from premium materials selected for specific operational requirements. The primary materials include 9CrSi (alloy tool steel known for high hardness and wear resistance), Cr12MoV and SKD-11 (cold work die steels offering exceptional wear resistance and impact toughness), making them suitable for various materials from soft waste to high-hardness plastics and wood.

Each blade undergoes specialized heat treatment and triple tempering processes to achieve a hardness of HRC 56-65, ensuring high rigidity and impact resistance. This advanced thermal treatment enhances the blade's microstructure, providing consistent cutting performance and extended service life even when processing challenging materials. The precision-engineered surfaces are burr-free, promoting smooth operation and reducing energy consumption during shredding operations.

Key Features & Benefits

Long Service Life

Designed for extended durability in demanding environments, our blades feature wear-resistant properties that significantly reduce downtime for blade changes and maintenance interventions.

Impact Resistance

The robust construction handles unexpected hard objects without damage, maintaining cutting efficiency and preventing operational disruptions during material processing.

High Rigidity

Prevents bending and deformation under heavy load conditions, ensuring stable and efficient shredding output over extended operational periods.

Precision Particle Control

Single-shaft design with sizing screens enables uniform particle size reduction, crucial for recycling applications where consistent output size matters.

Application Industries & Materials

These versatile blades are engineered for optimal performance across diverse material processing applications. Single-shaft shredder blades are particularly effective for softer materials where precise particle size control is essential.

Plastics & Polymers

Hard plastics, lumps, films, PET containers, and other polymer materials.

Rubber & Tires

Various rubber products, tires, and elastic materials for recycling operations.

Wood & Biomass

Wood blocks, pallets, forestry waste, and biomass materials.

Paper & Textiles

Paper waste, cardboard, various textiles, and fibrous materials.

Industries including recycling facilities, waste management, manufacturing plants, and textile processing will find these blades particularly effective for their shredding requirements, offering reliable performance in volume reduction applications.

Customization & Quality Assurance

We specialize in providing tailor-made blade solutions customized to your specific operational requirements. From exact dimensions and material specifications to specialized tooth configurations and coatings, we can engineer blades that perfectly match your single shaft shredder model and material stream.

Our commitment to quality is demonstrated through comprehensive quality assurance protocols including video outgoing-inspection and official machinery test reports. Each blade undergoes rigorous testing for hardness, dimensional accuracy, and performance characteristics before shipment, ensuring they meet or exceed OEM specifications.

Packaging & Delivery

Blades are securely packed in wooden cases with anti-rust protection, ensuring they arrive ready for installation.