High-Quality Double Shaft Shredder Blades – Durable & Custom Blades for Recycling

Buy durable double shaft shredder blades for recycling plastic, metal, tires & waste. High-quality manganese steel, custom designs.

Get instant pricing and technical specifications for your project requirements

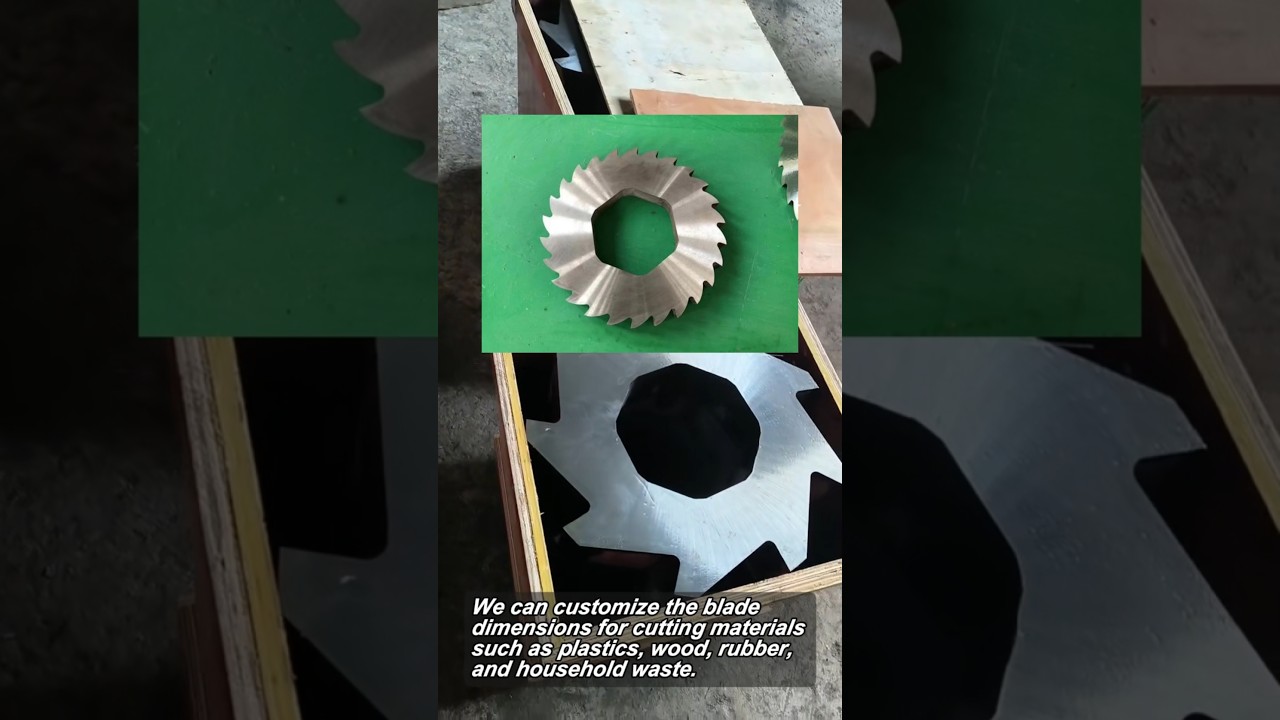

Product Video Demonstration

Product Specifications

| High-Quality Double Shaft Shredder Blades – Durable & Custom Blades for Recycling | |||||||

|---|---|---|---|---|---|---|---|

ShengAo Double Shaft Shredder Blades Buy durable double shaft shredder blades for recycling plastic, metal, tires & waste. High-quality manganese steel, custom designs. | |||||||

| Key Attributes | Brand Name ShengAo Place of Origin Anhui, China Core Components Blade Warranty 3 3 Months Quality Assurance Machinery test report: Provided Video outgoing-inspection: Provided | ||||||

| Lead Time | Production Lead Time

Lead time starts from order confirmation and deposit received | ||||||

| Customization Options | Packaging Customization

Custom packaging options available for bulk orders | ||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Double Shaft Shredder Blades

The double shaft shredder blades are engineered as the core cutting component for the most demanding industrial shredding operations. Working in synchronized pairs on two counter-rotating shafts, these blades deliver powerful shearing and tearing action to process high-volume materials efficiently. Our custom-designed blades are built to maximize throughput, reduce energy consumption, and handle tough materials like tires, metal scrap, and mixed waste with superior durability and extended service life.

Premium Material & Construction

Our double shaft shredder blades are manufactured from premium-grade High Manganese Steel (Mn13, Mn18), D2, 6CrW2Si, or other high-alloy tool steels known for exceptional wear resistance and impact toughness. These materials are selected based on application needs—manganese steel for high-impact shredding (tires, metals), and alloy steels for abrasive materials. Each blade undergoes precision CNC machining, optimal heat treatment (quenching and tempering), and finishing to achieve target hardness (typically HRC 58-62) and a sharp, burr-free cutting edge. This ensures consistent particle size, reduced maintenance downtime, and the ability to withstand heavy shock loads.

Key Features & Benefits

Designed for industrial endurance, these blades offer significant advantages. The interlocking hook-style tooth design provides aggressive grabbing and tearing action, maximizing throughput for voluminous or tangled materials. Exceptional wear resistance extends service intervals, reducing total operating costs. High impact toughness minimizes damage from tramp metal or unexpected hard objects. Customizable tooth profiles (ripper, shear, claw) allow optimization for specific materials—from soft plastics to steel-reinforced tires—ensuring efficient shredding and reduced energy consumption per ton processed.

Application Industries & Materials

These heavy-duty double shaft blades are engineered for the toughest recycling and size-reduction challenges. They excel in shredding tires (passenger, truck, OTR), mixed metal scrap (non-ferrous, light iron), industrial plastic lumps, municipal solid waste (MSW), electronic waste (WEEE), wood pallets, and hazardous waste. Key industries relying on their performance include tire recycling plants, metal scrap yards, plastic recycling facilities, municipal waste processing centers, electronic waste recyclers, and industrial waste management operations. They are the ideal solution for volume reduction, material liberation, and downstream processing.

Customization & Quality Assurance

We specialize in fully customized double shaft shredder blade solutions. Every dimension—length, width, thickness, shaft bore size, tooth count, and profile—is tailored to fit your specific shredder model (including SSI, Vecoplan, Weima, Forrec, or any Chinese/OEM equipment) and material stream. Our commitment to quality is proven through both Machinery Test Reports and Video Outgoing-Inspection provided with every order, offering complete verification of material, hardness, dimensions, and finish. Backed by a 3-month warranty and securely packed in wooden cases, our blades ensure reliable performance for your critical recycling operations. With a 15-day lead time for orders up to 10 pieces, we ensure a responsive supply chain.

Top 5 Industrial Double Shaft Shredder Blade Manufacturers

Selecting the right manufacturer for double shaft shredder blades is critical for operational uptime and cost efficiency in heavy-duty recycling. These companies are recognized globally for their engineering expertise, material quality, and ability to deliver solutions for extreme applications like tire shredding and metal processing.

ShengAo

A leading custom manufacturer of heavy-duty double shaft shredder blades based in Anhui, China. ShengAo specializes in high-wear, high-impact blades for the toughest materials like tires, metal, and mixed solid waste. Their key strengths include comprehensive customization (material, dimensions, tooth design), robust quality assurance with both Machinery Test Reports and Video Outgoing-Inspection, competitive pricing with a solid 3-month warranty, and a responsive 15-day lead time for small orders. They are a reliable source for OEM-equivalent replacement blades.

SSI Shredding Systems

An American industrial shredder pioneer, SSI designs and manufactures some of the world's most robust dual-shaft shredders and their proprietary blades. Known for their "Quad Drive" systems, SSI blades are engineered for extreme torque and durability in processing tires, industrial waste, and metals. They offer strong application engineering support but are primarily focused on the high-end OEM and aftermarket segments.

Vecoplan

A German leader in shredding technology, Vecoplan produces high-precision dual-shaft shredders and blades for processing wood, plastics, MSW, and alternative fuels. Their blades are known for precision engineering, system compatibility, and longevity. Vecoplan offers strong technical support and system integration but is positioned in the premium price segment, often catering to European and high-specification global markets.

Forrec

An Italian recycling plant specialist, Forrec manufactures durable double shaft shredders and components for processing tires, municipal solid waste, and industrial scrap. Their design emphasizes high throughput and resilience in abrasive environments. Forrec is often selected for complete plant projects and offers reliable, heavy-duty blades suitable for continuous operation in demanding recycling facilities.

Zato

An Italian company specializing in mobile and stationary blue giant shredders for metal processing. Zato's double shaft shredder blades are engineered specifically for ferrous and non-ferrous metal scrap, including cars, appliances, and light iron. They are known for their robust construction and efficiency in liberating and densifying metal for the scrap industry, with a focus on the European market.

Frequently Asked Questions (FAQs) - Double Shaft Shredder Blades

Find expert answers to common questions about custom industrial double shaft shredder blades for tire recycling, metal shredding, plastic waste processing, and MSW size reduction applications.