High-Performance Single Shaft Shredder Blades for Tyre, Rubber & Plastic Recycling

Boost recycling efficiency with heavy-duty shredder blades for tyre, rubber & plastic. High-wear resistance, custom designs. Free quote & global shipping.

Get instant pricing and technical specifications for your project requirements

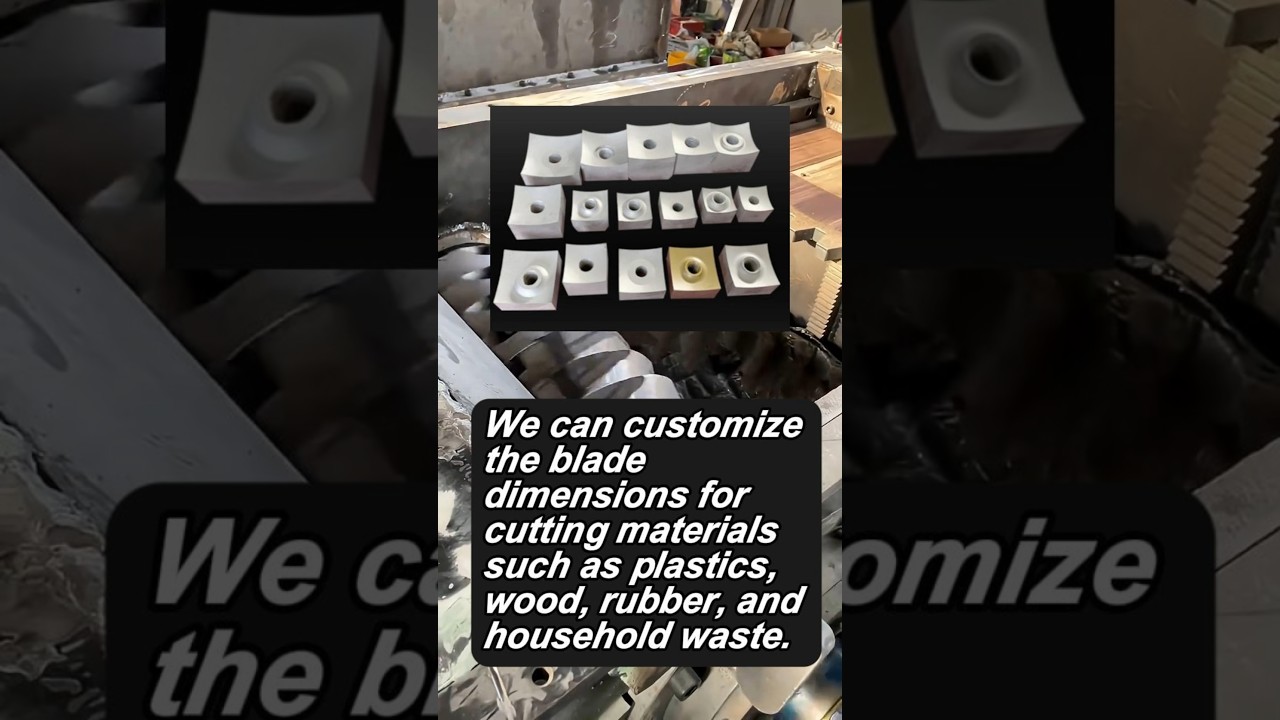

Product Video Demonstration

Product Specifications

| ShengAo High-Performance Rubber Cutting Blades for Recycling Machinery | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

High-Performance Single Shaft Shredder Blades for Tyre, Rubber & Plastic Recycling Boost recycling efficiency with heavy-duty shredder blades for tyre, rubber & plastic. High-wear resistance, custom designs. Perfect High Cutting Efficiency and Long Service Life. | ||||||||||

| Key Specifications | Brand Name ShengAo Product Name Rubber cutting blades Type Rubber Recycling Machinery Material Tool steel, D2/SKD11 Hardness HRC 56-63 Application Machine Plastic/Rubber Recycling Shape Square Precision ±50 micron Size Customized Packaging Carton Box + Wooden Case | |||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core 6 Warranty: 6 Months D2 Core Material: Tool Steel D2/SKD11 | |||||||||

| Lead Time | Quantity-Based Production Lead Time

Lead time starts from order confirmation and deposit received. Custom sizes may affect lead time. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our High-Performance Rubber Cutting Blades

The rotor and counter blades are the core components of any single shaft shredder, directly responsible for the cutting efficiency and output quality. Specifically engineered for the demanding task of tire, rubber, and plastic recycling, our heavy-duty blades are precision-crafted to deliver maximum performance in high-impact, high-wear environments. Built for longevity and consistent cutting action, they ensure optimal size reduction of tough materials into uniform granulate for further processing or recycling.

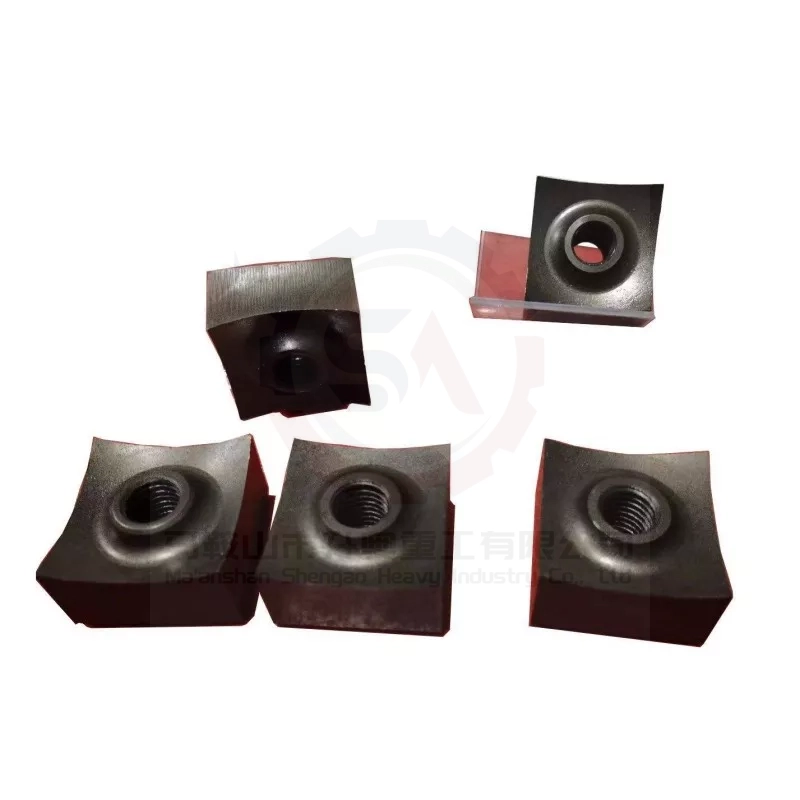

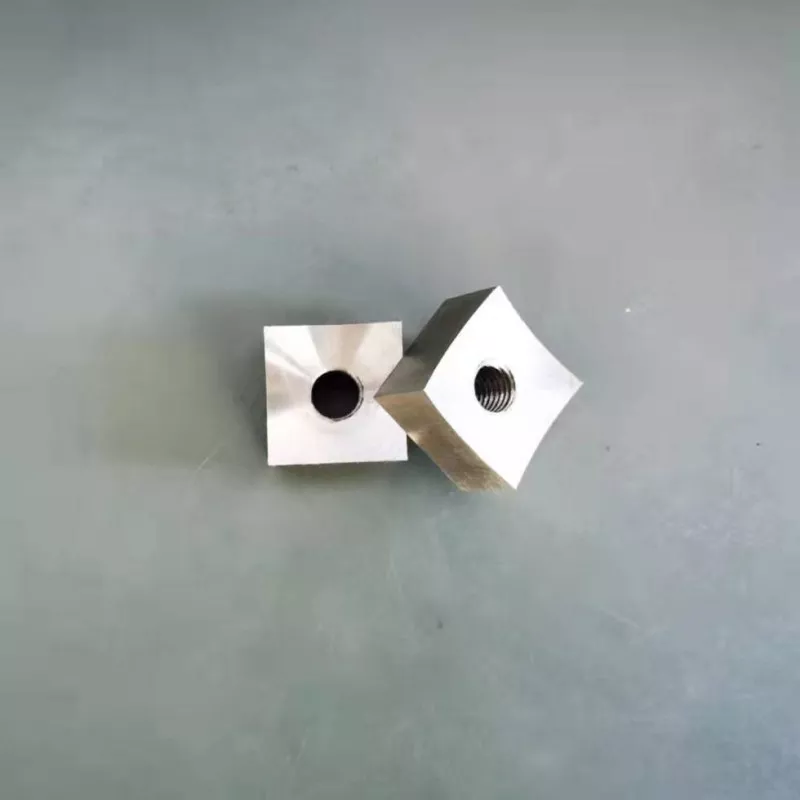

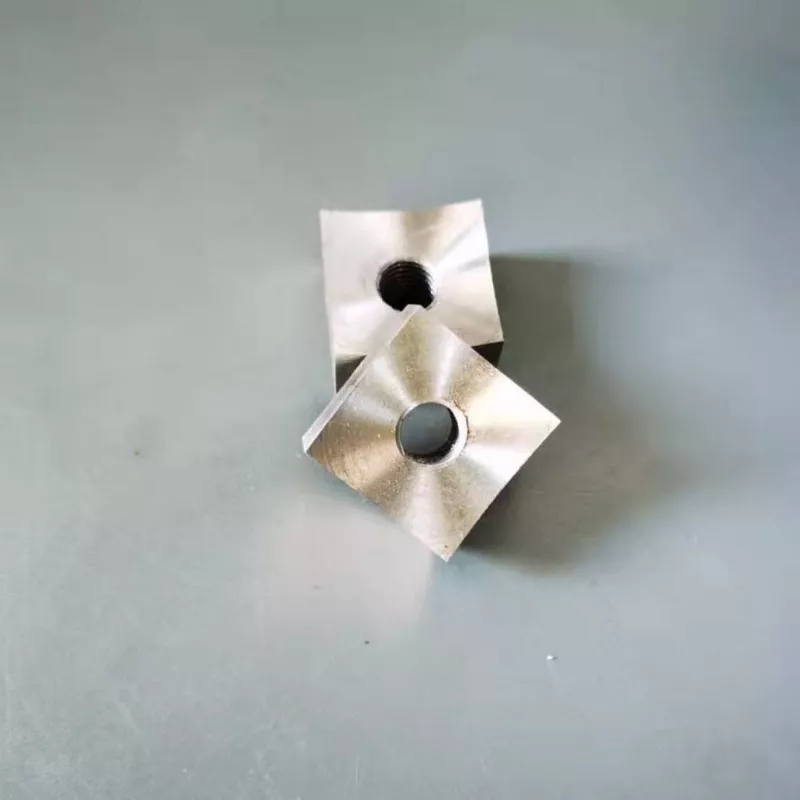

Premium Material & Construction

Our blades are manufactured from premium Tool Steel grades, primarily D2/SKD11, which are renowned for their exceptional wear resistance and ability to maintain a sharp edge under heavy load. This high-chromium, high-carbon steel is heat-treated to achieve a hardness of HRC 56-63, providing the perfect balance between hardness for wear resistance and toughness to prevent chipping. Each square blade undergoes precision CNC machining and grinding to achieve a dimensional tolerance within ±50 microns, ensuring a high-precision, burr-free cutting surface. This precision is critical for consistent cutting performance, smooth operation, and maintaining the efficiency of your plastic and rubber recycling machinery.

Key Features & Operational Benefits

The cornerstone of our blades is their ability to deliver a long service life in the most abrasive applications. The high wear resistance of D2/SKD11 steel dramatically extends intervals between sharpening or replacement, minimizing costly machine downtime and maintenance. The high hardness (HRC 56-63) ensures the cutting edge stays sharp longer, maintaining high cutting efficiency and consistent particle size. Furthermore, the robust construction provides high rigidity and impact resistance, preventing deformation and allowing the blades to handle the extreme forces encountered when shredding tires, dense rubber blocks, and hard plastics. This combination translates directly to increased productivity and lower total cost of ownership.

Application Industries & Materials

These high-performance rubber cutting blades are purpose-built for the recycling industry's most challenging materials. They excel in processing whole tires (car and truck), rubber scraps and trimmings, EPDM, silicone, industrial rubber products, hard plastics (HDPE, PP, PVC lumps), and plastic purgings. Key industries that depend on their reliability include tire recycling plants, rubber product manufacturers, plastic recycling facilities, and waste management operations focused on ELT (End-of-Life Tire) processing. Whether installed in a primary shredder or a fine granulator, these blades provide the durable cutting solution needed to transform tough, elastic, and abrasive materials into valuable secondary raw materials.

Customization & Quality Assurance

We specialize in providing completely customized blade solutions. From the overall size and thickness to the bore hole pattern and cutting edge geometry, we manufacture blades to fit your specific single shaft shredder model perfectly. Our commitment to quality is transparent and verifiable. We provide an official machinery test report and a video outgoing-inspection for every order, allowing you to verify quality before shipment. Backed by a solid 6-month warranty, your investment is protected. Blades are securely packed in carton boxes inside sturdy wooden cases to ensure they arrive at your facility undamaged and ready for immediate installation and peak performance.

Top 5 Single Shaft Shredder Blade Manufacturers for Rubber & Tire Recycling

Selecting the right blade manufacturer is critical for efficient tire and rubber recycling, where wear resistance and toughness are paramount. These companies lead in material science, precision engineering, and delivering durable solutions for demanding shredding applications.

ShengAo

A specialized manufacturer of high-performance rubber cutting blades for single shaft shredders. Their focus is on the demanding tire and rubber recycling market. Blades are precision-made from premium D2/SKD11 Tool Steel with a hardness of HRC 56-63, offering exceptional wear resistance for abrasive materials. Key advantages include a strong 6-month warranty, comprehensive quality documentation (machinery test report, video inspection), and full customization of size and specifications. They are known for providing cost-effective, long-lasting blade solutions that boost efficiency in tire recycling machinery.

Rapid Granulator

A Swedish world leader in granulation technology. Rapid designs and manufactures its own precision knives for its energy-efficient single shaft granulators. While focused on plastics, their engineering expertise in clean cutting, consistent particle size, and low energy consumption provides a high-quality benchmark. Their solutions are often integrated into recycling lines for technical plastics and post-industrial waste.

Vecoplan

A German leader in shredding and recycling technology. Vecoplan manufactures durable single and double shaft shredders along with their corresponding high-quality knives. Known for robust construction, innovative cutting chamber designs, and strong application support, they provide reliable solutions for processing plastics, wood, and waste, including challenging streams.

Foremost Machine Builders

A long-established US manufacturer of size reduction equipment. Foremost produces reliable granulators and their corresponding knives, with a strong emphasis on durability, ease of maintenance, and consistent performance in processing various plastic and rubber materials, well-supported in the North American market.

WEIMA

A prominent German manufacturer of shredding and granulating machinery. WEIMA produces durable knives for their own single shaft shredders, focusing on energy efficiency, low-noise operation, and high throughput for a wide range of materials including plastics and industrial waste, known for system stability and low maintenance.

Frequently Asked Questions (FAQs) - Rubber Cutting Blades

Find expert answers to common questions about ShengAo High-Performance Rubber Cutting Blades for single shaft shredders in tire, rubber, and plastic recycling.