High-Performance PP & PVC Crusher Blades| Heavy-Duty Industrial Shredder Blades

Heavy-duty plastic crusher blades for PP, Nylon, PVC. Wear-resistant 500 alloy & PC400 for strong shredding. Durable industrial blades for plastic recycling.

Get instant pricing and technical specifications for your project requirements

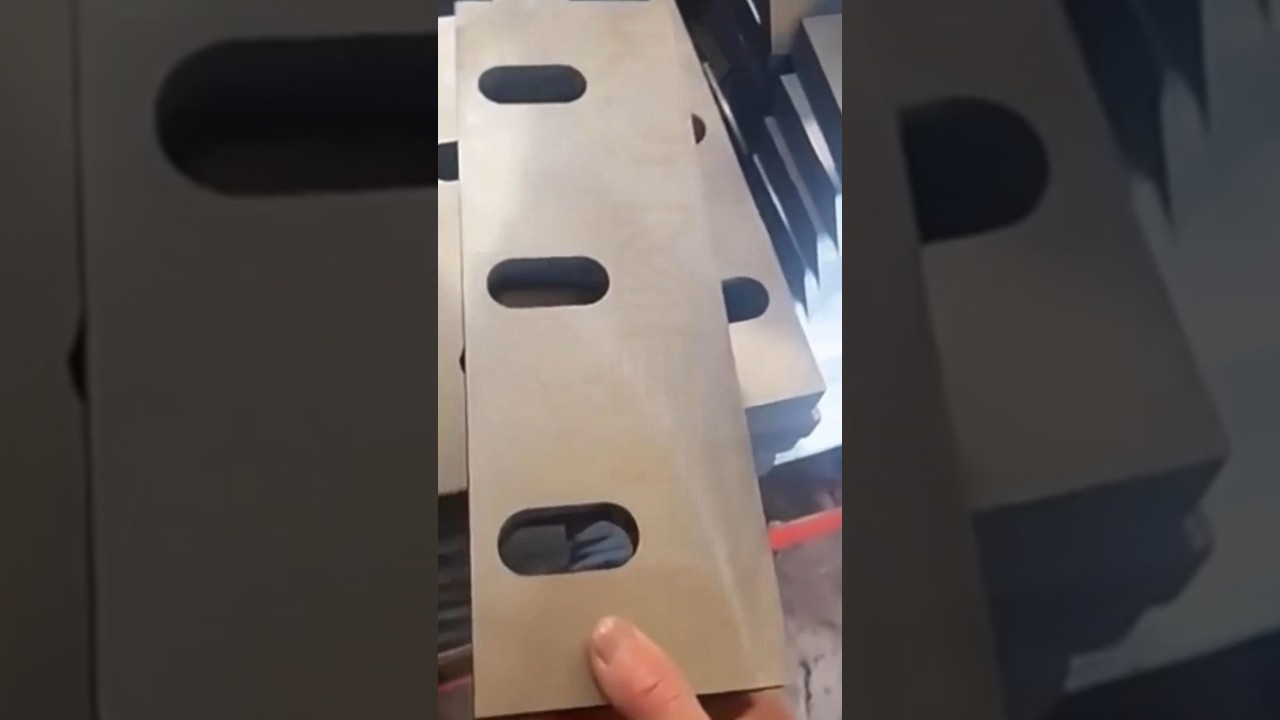

Product Video Demonstration

Product Specifications

| ShengAo Plastic Shredder Blades - Tool Steel Industrial Blades | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Heavy-duty plastic crusher blades for PP, Nylon, PVC. Wear-resistant 500 alloy & PC400 for strong shredding. Durable industrial blades for plastic recycling. High-performance, wear-resistant shredder blades manufactured from premium tool steel. Designed for heavy-duty industrial plastic recycling applications including PP, PVC, and Nylon. | ||||||||||||||||

| Key Attributes | Brand Name ShengAo Type Blade Product Name Plastic shredder blades Blade Material Tool Steel Place of Origin Anhui, China Core Components Tool Steel Standard Delivery Time 7-30 days | |||||||||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core 3 Warranty: 3 Months TS Core Components: Tool Steel | |||||||||||||||

| Delivery Information | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. | |||||||||||||||

| Customization Options | Available Customization

Note: Custom specifications and packaging solutions available upon request for bulk orders. | |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Plastic Shredder Blades

Plastic shredder blades are the critical cutting components in industrial recycling systems, engineered to efficiently reduce plastic materials into consistent flakes for reprocessing. These heavy-duty blades work in precision alignment with stationary counter blades to achieve optimal cutting action and particle size control. Our ShengAo plastic shredder blades are specifically designed for maximum performance, durability, and operational efficiency in demanding plastic recycling applications, particularly for challenging materials like PP, Nylon, and PVC that require specialized cutting solutions.

Premium Material & Construction

Our plastic shredder blades are manufactured from premium tool steel alloys selected for their exceptional combination of wear resistance, hardness, and toughness. We utilize specialized steel grades including wear-resistant 500 alloy and PC400 tool steel that provide superior performance in demanding plastic processing applications. Each blade undergoes precision CNC machining, advanced heat treatment processes, and meticulous grinding to achieve optimal geometry and a razor-sharp cutting edge. The blades feature a high-precision, burr-free surface that ensures smooth operation, consistent cutting performance, and minimal energy consumption during continuous industrial recycling operations.

Key Features & Operational Benefits

Engineered for industrial performance, our plastic shredder blades deliver significant operational advantages. The exceptional wear resistance of our specialized tool steel alloys extends blade life by 40-60% compared to standard blades, dramatically reducing replacement frequency and associated downtime costs. The blades maintain consistent cutting performance through extended production runs, ensuring uniform particle size and optimal material flow for downstream processing. With high rigidity and impact resistance, these blades prevent deformation under heavy loads and withstand occasional hard contaminants. The efficient 10-30 day delivery schedule (based on order quantity) ensures minimal disruption to your operations. These features collectively enhance productivity and reduce operating costs in industrial plastic recycling facilities.

Application Industries & Materials

These specialized plastic shredder blades are engineered for challenging plastic processing applications across multiple industries. They excel in processing: Polypropylene (PP) - automotive parts, containers, packaging; Polyvinyl Chloride (PVC) - pipes, profiles, fittings; Nylon (PA) - engineering components, fibers, industrial parts; Polyethylene (PE) - bottles, film, containers; ABS and Engineering Plastics - electronic housings, consumer products; Plastic Film and Sheets - packaging materials, agricultural film. Key industries served include plastic recycling facilities, injection molding plants, pipe/profile manufacturers, automotive plastic processors, packaging manufacturers, and industrial plastic product manufacturers. These blades are ideal for central granulators, standalone shredders, and recycling systems handling abrasive or challenging plastic materials.

Customization & Quality Assurance

We specialize in providing customized plastic shredder blade solutions engineered for your specific equipment and material requirements. Our customization capabilities include blade dimensions, cutting edge geometries, hole patterns, and material specifications optimized for your particular application. Our commitment to quality is verified through comprehensive documentation: we provide both detailed machinery test reports and video outgoing-inspection for every order, ensuring complete transparency and confidence in your purchase. We back our products with a 3-month warranty on the core tool steel components. Delivery schedules are efficient and volume-based: 10 days for 1-50 pieces, 20 days for 51-100 pieces, and 30 days for 101-200 pieces. Bulk orders over 200 pieces are scheduled through negotiation. Packaging in secure cartons is available for orders of 300 pieces or more.

Top 5 Industrial Crusher Blade Manufacturers

Selecting the right manufacturer for industrial crusher blades is crucial for maintaining operational efficiency, minimizing downtime, and ensuring cost-effective recycling operations. These brands are recognized for their engineering expertise, material science, and proven performance in demanding plastic processing environments.

ShengAo

A leading manufacturer specializing in high-performance plastic shredder blades made from premium tool steel alloys including wear-resistant 500 alloy and PC400. Their blades are engineered for exceptional durability and performance in processing challenging plastics like PP, Nylon, and PVC. Key advantages include comprehensive quality assurance with both machinery test reports and video inspections, a 3-month warranty on core components, efficient 7-30 day delivery schedules based on order quantity, and carton packaging available for orders of 300+ pieces. Recognized for providing reliable, high-performance blade solutions that enhance productivity in industrial plastic recycling and processing operations worldwide.

Rapid Granulator

A Swedish world leader in granulation technology, Rapid manufactures precision plastic crusher blades focusing on clean cutting action, consistent particle size, energy efficiency, and quiet operation. Their blades are designed for optimal performance in their own granulator systems and are known for innovative rotor and cutting geometry designs.

Vecoplan

The German recycling technology specialist offers robust plastic crusher blades as part of their comprehensive size reduction solutions. Vecoplan blades are known for durability in demanding applications, efficient cutting chamber designs, and the ability to handle large volumes of plastic scrap, including films, lumps, and purgings.

Foremost Machine Builders

An established American manufacturer of size reduction equipment, Foremost produces durable plastic crusher blades known for their rugged construction, reliable performance, and good availability of replacement parts. Their blades are commonly used in North American plastic processing facilities.

WEIMA

A German manufacturer of shredding and granulating systems, WEIMA produces durable plastic crusher blades focused on energy efficiency, low-noise operation, and high throughput for processing plastics, wood, and other materials in industrial applications across Europe and North America.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Plastic Shredder Blades with Tool Steel construction for industrial PP, PVC, and Nylon recycling applications.