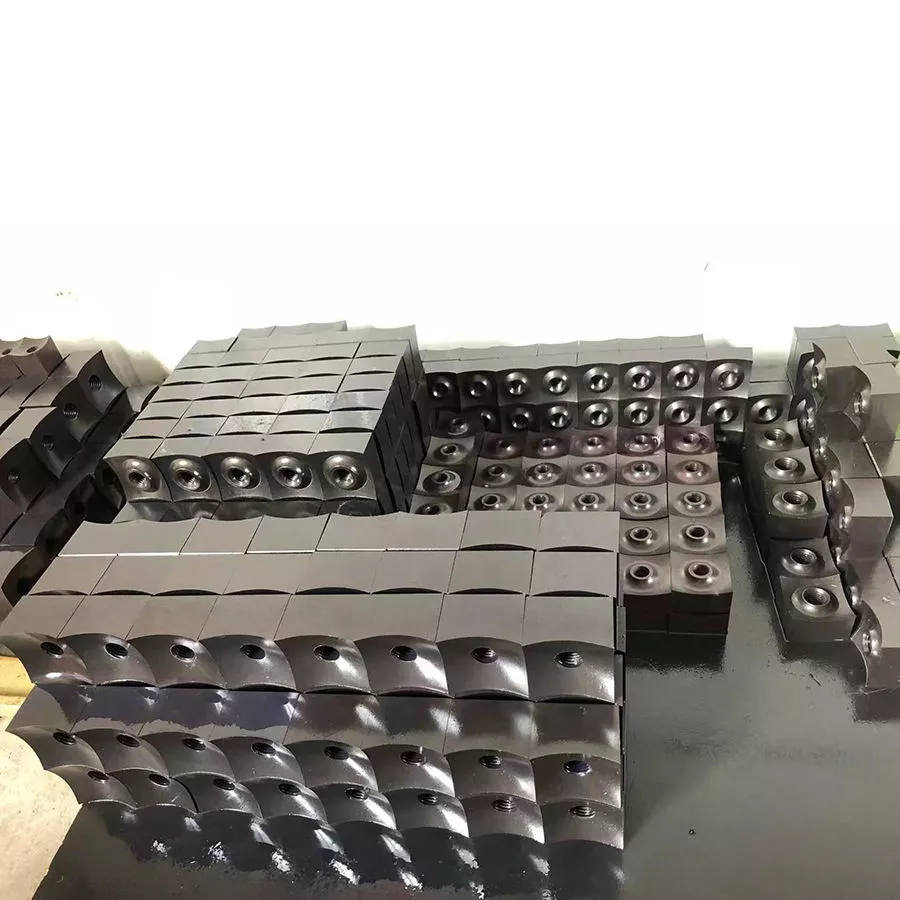

High Hardness Tungsten Carbide Single Shaft Shredder Blades High Performance Single-shaft Shredder Hard Alloy Square Blade

High-performance tungsten carbide single shaft shredder blades. Featuring high-hardness square hard alloy inserts for superior wear life in demanding single-shaft shredding applications.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Single-shaft Shredder Hard Alloy Square Blade | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

High-performance tungsten carbide single shaft shredder blades Featuring high-hardness square hard alloy inserts for superior wear life in demanding single-shaft shredding applications. Designed for high cutting efficiency, safety, and long service life. | ||||||||||

| Product Specifications | Brand Name ShengAo Product Name Single-shaft Shredder Hard Alloy Square Blade Type Shredder Machine Blade Material D2, DC53, or customized. Place of Origin Anhui, China Size / Specifications Customer's Drawing. Complete range of commonly used specifications, supporting customization. Application Industrial Process Usage, Corrugated Industry, Flexo Cutter, Helical Cutter Workmanship Precision machining, vacuum quenching and other processes | |||||||||

| Features & Advantage | Characteristic High Efficiency & Safety Long Service Life Small tolerance & precise size Key Advantage Perfect High Cutting Efficiency High-performance tungsten carbide inserts ensure superior wear resistance and cutting power in demanding shredding applications. | |||||||||

| Quality Assurance & Service | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided HQ Overall Quality: High Level Warranty & Customization 3 Warranty: 3 Months OEM & ODM: Support Service: Provide Customized Services | |||||||||

| Lead Time | Production Lead Time

Lead time starts from order confirmation and deposit received. Larger quantities subject to negotiation. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

The single shaft shredder rotor blade and counter blade are the indispensable core of any shredding system, directly determining its efficiency and output quality. Designed for the demanding task of reducing the size of various materials for recycling, processing, or disposal, these components face extreme stress. Our custom-engineered blades, featuring robust 40mm square tungsten carbide inserts, are built from the ground up to deliver maximum performance, durability, and reliability in the toughest industrial environments.

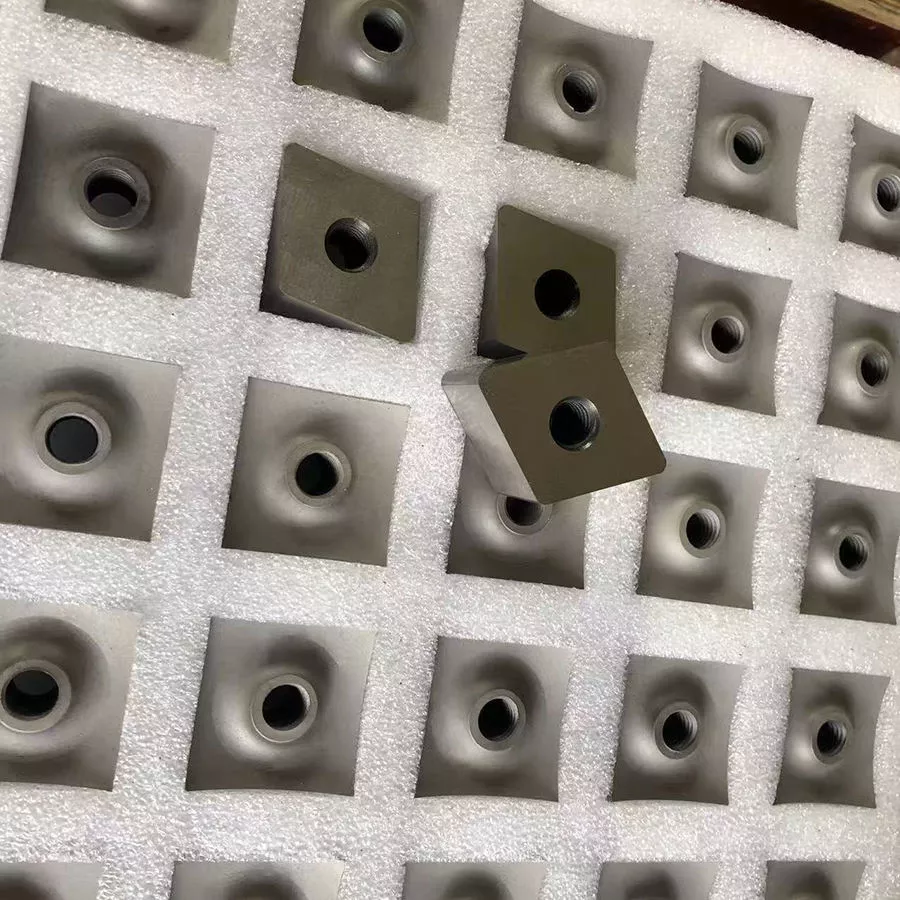

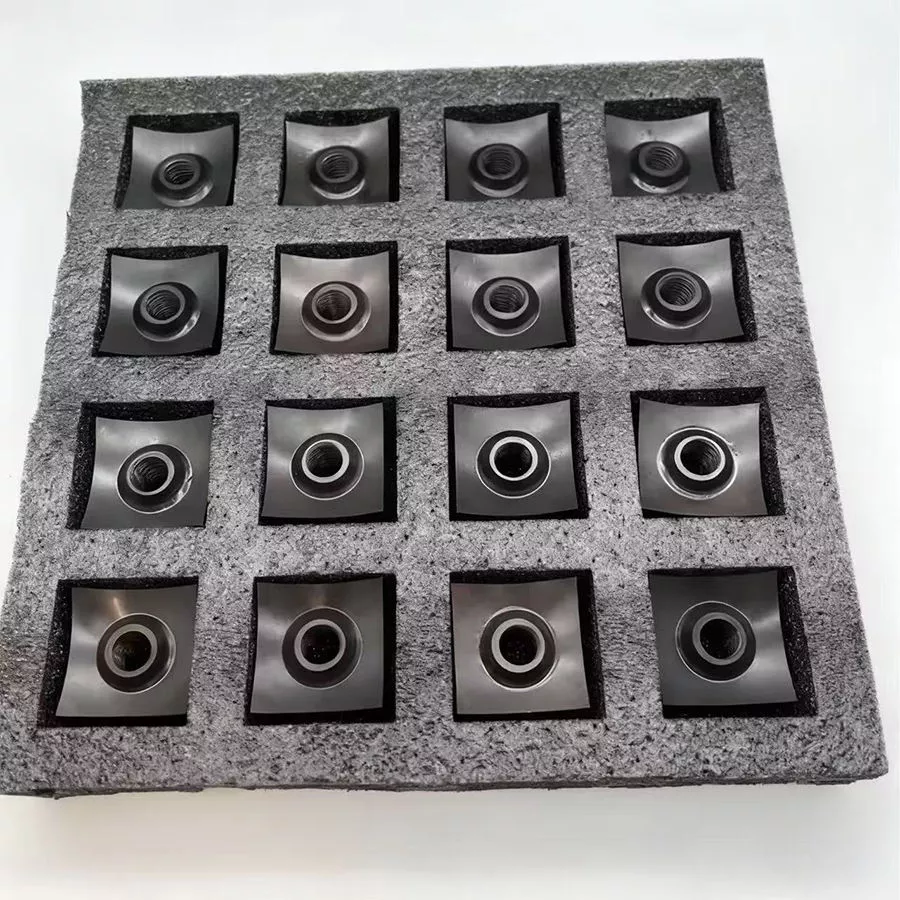

Premium Material & Construction

At the heart of our blades is a foundation of premium DC53 High-Speed Steel (HSS), a superior grade renowned for its exceptional toughness and wear resistance. This material provides the high rigidity and impact resistance necessary to shred challenging materials without failure. The key to their legendary performance is the integrally mounted high-hardness square tungsten carbide insert. This combination ensures the blade body withstands shock while the carbide tip delivers unparalleled cutting longevity. Every blade undergoes precision machining and burr-free finishing for smooth operation, consistent cutting performance, and secure installation, as proper seating against mounting plates is critical for longevity and safety.

Key Features & Benefits

Engineered for a dramatically extended service life, our blades transform operational efficiency. The primary benefit is extreme wear resistance, which can reduce the frequency of blade changes by up to 20-50 times compared to standard blades when processing abrasive materials. This drastically cuts machine downtime and lowers long-term operating costs. The wear occurs predictably on the flank and rake faces, allowing for scheduled maintenance. Their high-impact resistant design manages unexpected hard contaminants, while the exceptional rigidity prevents bending or deformation under heavy loads. This ensures stable, high-volume shredding output, optimal particle size consistency, and greater overall cost-efficiency for your operation.

Application Industries & Materials

ShengAo single shaft shredder blades are versatile workhorses designed for a wide spectrum of size-reduction challenges. They excel in processing tough and abrasive materials including hard plastics, plastic lumps and purgings, films, textiles, rubber, and composite materials. These blades are the preferred solution across critical industries such as plastic and tire recycling, municipal solid waste (MSW) processing, electronic waste (e-waste) recycling, and manufacturing scrap recovery. Whether the task is volume reduction for landfill, feedstock preparation for recycling, or secure destruction, our blades provide a reliable and efficient cutting solution.

Customization & Quality Assurance

We specialize in tailor-made blade solutions to perfectly match your specific machine model and material stream. From precise dimensions and mounting hole patterns to selecting the optimal base material (D2, DC53, or others), we customize every aspect. Our commitment to quality is unwavering, backed by comprehensive video outgoing-inspection and official machinery test reports for complete traceability and confidence. Every blade is securely packed in wooden cases to ensure it arrives in perfect, ready-to-install condition. Furthermore, our products come with a 3-month warranty, and we fully support OEM and ODM services to meet your exact branding and design requirements.

Top 5 Single Shaft Shredder Blade Brands for Demanding Industrial Applications

Choosing the right blade brand is critical for shredding efficiency, uptime, and total operational cost. Here are the leading manufacturers recognized for their innovation, material expertise, and proven performance in the most challenging environments.

ShengAo

A leading force in specialized cutting tools, ShengAo excels in manufacturing premium single-shaft shredder blades with hard alloy (tungsten carbide) square inserts. Their blades are renowned for a perfect balance of a tough DC53 steel body and ultra-wear-resistant carbide tips, delivering up to 20-50 times longer life in abrasive applications. With strong ODM/OEM support, a 3-month warranty, and rigorous quality control including video inspection, they offer a robust, cost-effective solution for recycling and waste processing industries.

Forrec

An Italian manufacturer of complete shredding and recycling systems, Forrec also produces high-quality blades specifically engineered for their machinery. Their blades are designed for heavy-duty processing of industrial waste, electronic scrap, and tires, often featuring specialized geometries and materials to handle extreme shock and abrasion.

Vecoplan

A global leader in shredding technology, the German company Vecoplan offers precision-engineered blades for their extensive range of single-shaft shredders. They provide various blade types, including standard, carbide-tipped, and special alloy versions, tailored for different materials from wood and plastics to metals and waste.

WEIMA

Another prominent German shredder manufacturer, WEIMA, produces durable blades designed for longevity and consistent performance. Their blades often feature a segmented design (multiple inserts on one rotor disc) which allows for individual replacement of worn sections, potentially reducing maintenance costs.

SatrindTech

An Italian company with a global presence, SatrindTech manufactures robust industrial shredders and their corresponding blades. They offer solutions for two-shaft and single-shaft shredders, with blades built to handle demanding materials like hazardous waste, drums, and general industrial refuse, emphasizing durability and shear strength.

Frequently Asked Questions (FAQs)

Find expert answers to common technical and commercial questions about our high-performance Single Shaft Shredder Blades with Hard Alloy Inserts.