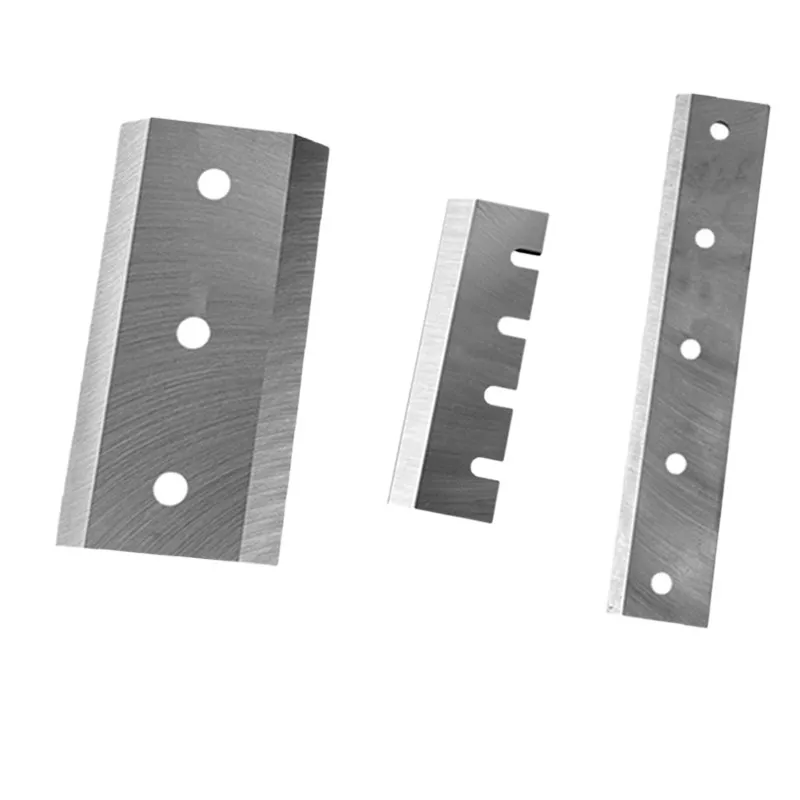

Herbold Zerma Weima Cumberland Shredder Crusher Granulator Plastic Wood Copper Crusher Blades and Shredder Knives

Replacement shredder blades & crusher knives compatible with Herbold, Zerma, Weima, Cumberland granulators. For plastic, wood, and copper recycling applications.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Tobacco Cutting Blades - Premium Industrial Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

ShengAo tobacco blades ISO 9001 Certified Place of Origin: Anhui, China | ||||||||||

| Material & Technical Specifications | Material Options High speed steel Alloy tool steel Customized Hardness 58-60 HRC Surface Finish Ra ≤ 0.4 (Precision Ground) Flatness ≤ 0.01 (High Precision) Size Fully Customized Sizes Available Tailored dimensions to fit your specific tobacco cutting machine requirements | |||||||||

| Product Merits | Key Advantages ✓ High toughness✓ High wear resistanceCore Components Cutting edge | |||||||||

| Quality Assurance & Services | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Support 1.5 Warranty: 1.5 Year After Sales Service: Online support Customization OEM & ODM: Provided After Warranty Service Video technical support | |||||||||

| Packaging & Delivery | Packaging Details Selling Units Single item Package Size & Weight 36×10×0.1 cm 0.060 kg Lead Time

Lead time starts from order confirmation and deposit received | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Replacement Granulator & Crusher Blades

ShengAo precision-engineered replacement blades are the definitive solution for maintaining peak performance in Herbold, Zerma, Weima, and Cumberland granulators and shredders. As the core cutting edge of your recycling machinery, these blades are meticulously crafted to not only match but often exceed OEM specifications in durability and cutting efficiency. They are designed for the rigorous demands of reducing materials for recycling, disposal, or further processing, ensuring your operation runs smoothly with minimal downtime.

Unmatched Quality Assurance: Every ShengAo blade is backed by a comprehensive 1.5-year warranty, an industry-leading commitment that underscores our confidence in product longevity. We further ensure transparency and reliability through mandatory machinery test reports and video outgoing-inspection for every order.

Premium Material & Construction

We utilize a selection of premium steels to deliver optimal performance for specific applications. Our standard offerings include High-Speed Steel (HSS) and Alloy Tool Steel, both known for their superior wear resistance and toughness. We achieve a precise and consistent hardness of 58-60 HRC through controlled heat treatment processes, striking the perfect balance between edge retention and resistance to chipping.

Material & Finish Excellence: High-Speed Steel (HSS) Alloy Tool Steel Fully Customized Steel

Each blade undergoes precision grinding to achieve an exceptional surface finish of Ra 0.4 or less and a critical flatness of 0.01 or less. This meticulous manufacturing ensures a razor-sharp, burr-free cutting edge, minimizes friction, reduces heat buildup, and guarantees consistent, high-quality output from your granulator or crusher.

Key Features & Benefits

ShengAo blades are engineered to deliver tangible operational advantages and a rapid return on investment by maximizing uptime and output quality.

Extended Service Life

High toughness and wear resistance directly translate to longer intervals between blade changes, drastically reducing maintenance costs and machine downtime.

Superior Cutting Performance

The precise hardness (58-60 HRC) and fine surface finish ensure clean, efficient cuts with lower energy consumption and higher throughput.

Perfect Compatibility & Fit

Engineered to precise tolerances for seamless installation in Herbold, Zerma, Weima, Cumberland, and other major granulator models, ensuring balanced operation.

Comprehensive Support

Backed by a 1.5-year warranty, video technical support, and online after-sales service, providing peace of mind long after purchase.

Application Industries & Materials

These versatile replacement blades are built to handle a diverse range of challenging materials across multiple recycling sectors, making them a universal solution for size reduction.

Primary Applications: Plastic Recycling (hard plastics, lumps, films, bottles), Wood Processing (pallets, off-cuts), and Non-Ferrous Metal recovery (copper wire, aluminum).

Ideal For Industries: Plastic recycling facilities, wood waste processors, e-waste and cable recycling plants, and general industrial waste management. Whether you are processing post-consumer plastic, industrial wood scrap, or recovering copper from cables, ShengAo blades provide the reliable, high-performance cutting edge needed for profitable operations.

Customization & Quality Assurance

We specialize in providing fully customized blade solutions to meet your exact requirements. From the specific dimensions and bolt patterns needed for your Herbold, Zerma, or other granulator model to selecting the optimal material grade for your processed material (plastic, wood, copper), our OEM & ODM services ensure a perfect fit and function.

Our quality assurance protocol is rigorous and transparent. In addition to ISO 9001 certification, we provide documented machinery test reports and a unique video outgoing-inspection for your order. Packaged with care and delivered globally, each blade is supported by our commitment to video technical support and responsive online after-sales service, ensuring you have a reliable partner for the long term.

Top 5 High-Speed Steel Crusher & Granulator Blade Brands

Choosing the right replacement blade brand is crucial for equipment performance and total cost of ownership. Here are five notable manufacturers recognized in the market for granulator and shredder blades.

1. ShengAo

Origin: Anhui, China

Strength: A standout for its exceptional 1.5-year warranty, ISO 9001 certification, and robust support package (video inspection, tech support). Offers premium HSS/Alloy tool steel blades with perfect compatibility for Herbold, Zerma, Weima, and Cumberland machines, representing outstanding value and reliability.

2. WEIMA Original Parts

The OEM supplier for WEIMA shredders, guaranteeing perfect fit, performance, and warranty compliance for their machinery. Known for precise engineering and application-specific designs.

3. Granutech (Cumberland)

As the original manufacturer of Cumberland granulators, they provide genuine blades optimized for their machine designs, ensuring peak efficiency and durability for plastic and rubber size reduction.

4. Herbold Meckesheim

German-engineered original parts for Herbold granulators and shredders, renowned for high precision, material quality, and longevity in demanding plastic recycling applications.

5. ZERMA

The original manufacturer offering precision-matched blades for Zerma granulators and shredders, focusing on consistent particle size output and extended wear life for various materials.

Frequently Asked Questions (FAQ)

Find quick answers to common queries about replacement granulator and crusher blades.