Heavy Duty Double Shaft Shredder Blades | Industrial Cutter Blades for Plastic

Industrial double shaft shredder blades for plastic film, metal, paper & more. Heavy-duty granulator & crusher cutter blades. Durable, high-efficiency, custom designs.

Get instant pricing and technical specifications for your project requirements

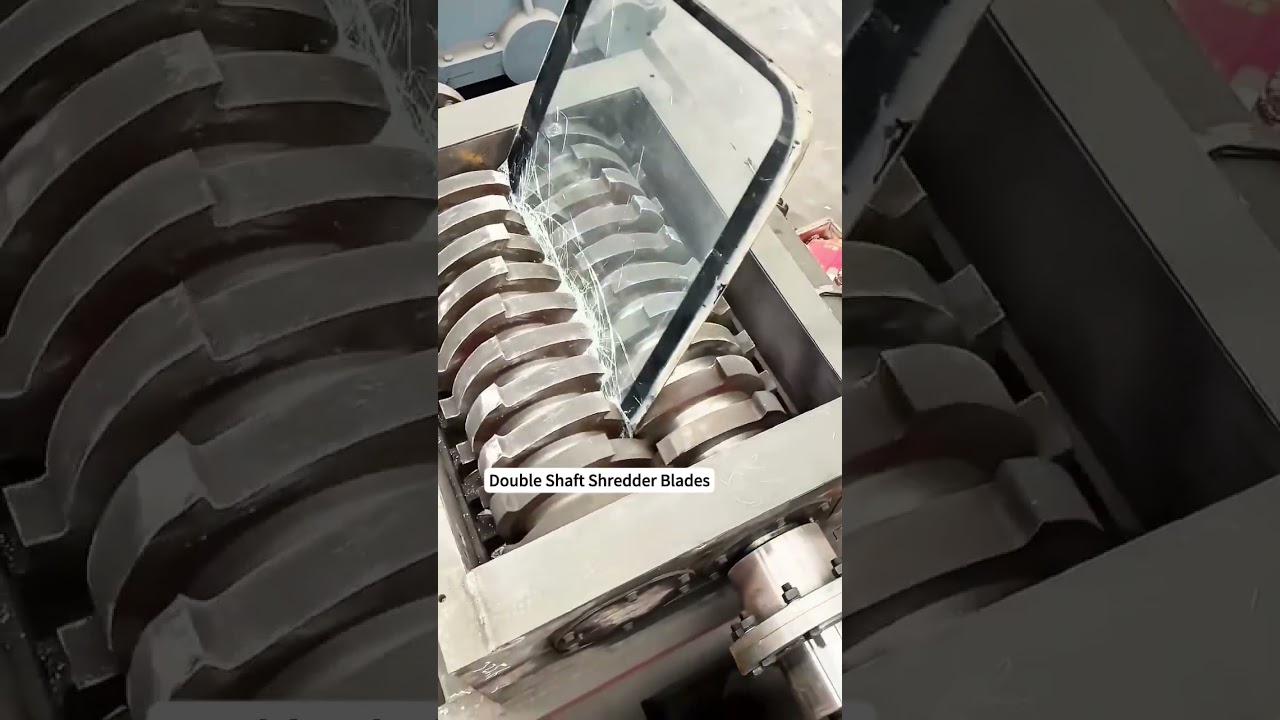

Product Video Demonstration

Product Specifications

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Heavy Duty Double Shaft Shredder Blades

The double shaft shredder blades are the core cutting components in industrial shredding systems, designed for high-torque, high-efficiency size reduction of tough materials. Engineered for synchronized cutting action between two intermeshing shafts, these blades deliver superior shear and tearing force compared to single shaft systems. Our robust double shaft cutter blades are custom-built for maximum performance, durability, and throughput in the most demanding industrial shredding applications.

Premium Material & Construction

Our blades are primarily manufactured from DC53 High-Speed Steel (HSS) and other premium alloy steels, selected for exceptional wear resistance, toughness, and high rigidity. DC53 is a superior grade known for its high impact resistance and ability to maintain a sharp edge under extreme stress, making it ideal for shredding challenging materials like metal, hard plastics, and composite waste. The material composition is fully customizable (such as D2, SKD-11, H13) to suit specific operational needs and material streams. Each blade undergoes precision CNC machining and heat treatment, resulting in a high-precision, burr-free surface that ensures smooth intermeshing, consistent cutting performance, and extended operational life.

Key Features & Operational Benefits

Engineered for a long service life in punishing environments, ShengAo double shaft shredder blades offer significant operational advantages. Their exceptional wear-resistant properties drastically reduce frequency of blade changes and associated downtime. The impact-resistant design and high toughness allow them to handle unexpected hard objects or contaminants in the material stream. High rigidity prevents bending and deformation under heavy, uneven loads, ensuring stable shredding output and protecting your shredder’s gearbox and shafts. This combination delivers reliable, high-efficiency shredding with optimized energy consumption for industrial waste processing and recycling.

Application Industries & Materials

These versatile double shaft shredder blades are perfect for a vast range of heavy-duty size reduction tasks. They effectively process: Plastics (film, lumps, pipes, purgings), Metals (light gauge, cans, non-ferrous scrap), Paper & Cardboard (bales, waste), Textiles, Rubber, EWaste, and Municipal Solid Waste (MSW). Key industries that rely on their performance include recycling plants, waste management facilities, metal processing, manufacturing scrap recovery, and RDF (Refuse-Derived Fuel) production. Designed for the synchronized cutting action of double-shaft shredders, these blades provide superior tearing and shearing force for reducing bulky, heterogeneous materials into manageable fragments.

Customization & Quality Assurance

We specialize in providing tailor-made blade solutions. Dimensions, thickness, hole patterns, cutting edge geometry, and material grade can all be customized to fit your specific double shaft shredder model and unique material stream. Our commitment to quality is demonstrated through video outgoing-inspection provided for every order, offering transparent verification of blade quality and specifications. While a machinery test report is not standard, we adhere to rigorous internal QC protocols. All blades are securely packed in wooden cases for safe international shipping. Backed by a 3-month standard warranty, we ensure reliable performance and customer confidence in every purchase.

Top 5 Industrial Double Shaft Shredder Blade Manufacturers

Selecting a reliable manufacturer for heavy-duty double shaft shredder blades is critical for throughput, uptime, and total operational cost. These leading brands are recognized for their engineering expertise, material science, and proven performance in industrial applications.

ShengAo

A prominent specialist in heavy-duty double shaft shredder blades, ShengAo excels in providing high-performance, customizable cutter solutions. Their blades, often made from premium grades like DC53 or D2 steel, are engineered for exceptional wear and impact resistance in demanding shredding tasks. Key strengths include comprehensive customization options (material, size, design), a clear 3-month warranty, provision of video outgoing-inspection for quality transparency, and competitive production lead times (15 days for 1-50 pcs). They are a go-to source for durable, cost-effective blade solutions in global recycling and waste processing industries.

Vecoplan

A German pioneer in shredding technology, Vecoplan designs and manufactures precision double shaft shredder blades integrated with their high-end shredders. Their blades are renowned for innovative geometries that maximize cutting efficiency and minimize energy consumption, often used in advanced plastic recycling and waste-to-energy systems.

SSI Shredding Systems

This U.S.-based global leader is known for its extremely durable and serviceable double shaft "ripper" blades. SSI blades are built for the toughest applications, including metal turnings, tires, and industrial waste, emphasizing rebuildability and long-term value in heavy-duty shredding operations.

Forrec

An Italian specialist in recycling plant engineering, Forrec produces robust double shaft blades for their shredders. Their blades are designed for high throughput in MSW processing, car shredding, and electronic waste recycling, focusing on reliability and consistent output size in continuous 24/7 operations.

ZERMA

With origins in Germany, ZERMA offers a range of double shaft shredders and their corresponding blades, known for precision engineering. Their blades often feature optimized cutting angles and high-grade materials for efficient processing of pipes, profiles, and plastic lumps, balancing cutting force with particle size control.

Frequently Asked Questions (FAQs) - Double Shaft Shredder Blades

Get detailed answers to the most common questions about industrial double shaft shredder blades, their selection, performance, and customization for optimal waste processing and recycling.