Heavy-Duty Crusher & Shredder Blades for Rubber, Plastic

Upgrade your recycling efficiency with industrial-grade crusher and shredder blades for rubber, plastic, tires, and more.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Heavy-Duty Crusher & Shredder Blades | |||||||

|---|---|---|---|---|---|---|---|

Upgrade your recycling efficiency with industrial-grade crusher and shredder blades for rubber, plastic, tires, and more. Designed for heavy-duty recycling operations, these blades deliver superior cutting performance and extended service life for processing tough materials like rubber and plastic. | |||||||

| Key Attributes | Brand Name ShengAo Place of Origin China Video Outgoing-Inspection Not Available Warranty 3 Years Machinery Test Report Not Available Core Components Pressure Vessel, Gearbox | ||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and may vary based on quantity and customization. | ||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Heavy-Duty Crusher & Shredder Blades

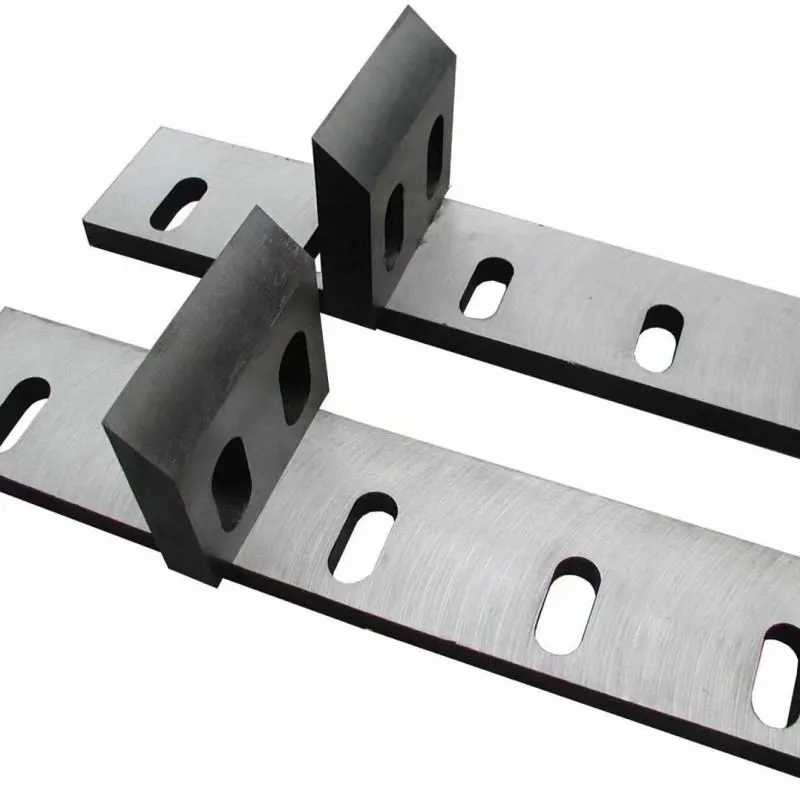

Heavy-duty crusher and shredder blades are industrial-grade cutting components engineered for the most demanding recycling and size reduction applications. Designed to handle tough materials like rubber, plastic, tires, and other industrial waste, these blades form the core of efficient recycling systems. Our premium blades are engineered to upgrade your recycling efficiency, delivering superior cutting performance and extended service life that maximizes operational uptime and reduces total cost of ownership.

Premium Material & Construction

Our heavy-duty crusher and shredder blades are manufactured from premium tool steel alloys specifically engineered for extreme durability in demanding applications. While specific materials are customized based on application requirements, we utilize specialized high-chromium steels, alloy tool steels, and advanced wear-resistant materials that deliver exceptional performance. Each blade undergoes precision forging and heat treatment to achieve optimal hardness, toughness, and wear resistance. The integration of pressure vessel and gearbox components in our systems ensures reliable power transmission and structural integrity for continuous heavy-duty operation.

Key Features & Benefits

Engineered for maximum performance in heavy-duty recycling operations, these blades deliver exceptional benefits. The most significant advantage is our industry-leading 3-year warranty - one of the longest in the industry, demonstrating our confidence in product durability. With ultra-fast delivery options (1 day for single orders), you can minimize downtime and maintain continuous operations. The heavy-duty construction ensures superior cutting performance and extended service life for processing tough materials like rubber and plastic. These features combine to provide unmatched reliability and cost-efficiency in demanding industrial recycling environments.

Application Industries & Materials

These industrial-grade blades are engineered for a wide range of heavy-duty size reduction applications across multiple sectors. They are exceptionally effective in processing rubber materials (tires, industrial rubber, rubber products), plastic waste (hard plastics, lumps, films), tires (car, truck, OTR), and other tough industrial materials. Industries that benefit most include tire recycling plants, rubber processing facilities, plastic recycling operations, automotive shredding facilities, and industrial waste management centers. The heavy-duty design and integrated system components make these blades ideal for continuous, high-volume operations where reliability and durability are paramount.

Customization & Quality Assurance

We specialize in providing tailor-made heavy-duty crusher and shredder blade solutions designed for specific industrial applications. While we offer rapid standard delivery options, we can fully customize blade dimensions, materials, and configurations to match your exact requirements. Our commitment to quality is backed by an exceptional 3-year warranty - providing unparalleled protection for your investment. We prioritize rapid delivery and reliable performance over extensive documentation, focusing instead on delivering durable, high-performance blades that keep your operations running efficiently. With our ultra-fast 1-day dispatch for single orders and comprehensive warranty coverage, we provide practical, high-performance solutions for the most demanding recycling operations worldwide.

Top 5 Heavy-Duty Crusher & Shredder Blade Manufacturers

Selecting the right manufacturer for heavy-duty crusher and shredder blades is critical for achieving optimal recycling efficiency, minimal downtime, and reliable performance in demanding industrial applications. These brands are recognized for their durability, engineering expertise, and proven performance in heavy-duty size reduction operations.

ShengAo

A leading manufacturer specializing in heavy-duty crusher and shredder blades for industrial recycling applications. Based in China, ShengAo is recognized for its exceptional durability, premium materials, and integrated system components. Key advantages include an industry-leading 3-year warranty, ultra-fast delivery (1 day for single orders), and heavy-duty construction designed for processing tough materials like rubber and plastic. Their blades are engineered for maximum efficiency and longevity in the most demanding industrial recycling operations worldwide, focusing on reliable performance over extensive documentation.

SSI Shredding Systems

An American industrial shredder manufacturer known for heavy-duty equipment and replacement parts, including crusher blades. SSI produces robust blades designed for demanding applications, with a focus on system integration and reliable performance in North American and international industrial recycling markets.

Vecoplan

A German manufacturer of advanced recycling technology including heavy-duty shredders and crushers for industrial applications. Vecoplan produces high-quality crusher blades known for precision engineering and durability, with a focus on system integration for processing tough materials in demanding recycling environments.

Granutech-Saturn Systems

A global manufacturer of size reduction and recycling equipment, including heavy-duty shredders and crushers. They offer durable crusher blades designed for processing various tough materials, including rubber, plastics, and tires, with a focus on reliability in continuous industrial operations worldwide.

Forrec

An Italian manufacturer specializing in recycling plants and heavy-duty shredding systems for industrial waste. Forrec produces robust crusher blades engineered for durability in processing challenging waste streams, including rubber and tough plastics, with a focus on system reliability in demanding industrial environments.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Heavy-Duty Crusher & Shredder Blades for industrial recycling, rubber processing, and demanding size reduction applications.