H13 Recycled Plastic Wood Metal Double Shaft Shredder Blade New Condition Cutting Machine Blade

New H13 steel double shaft shredder blades for recycled plastic, wood, and metal. High-performance cutting machine blades offer superior toughness and heat resistance for demanding conditions.

Get instant pricing and technical specifications for your project requirements

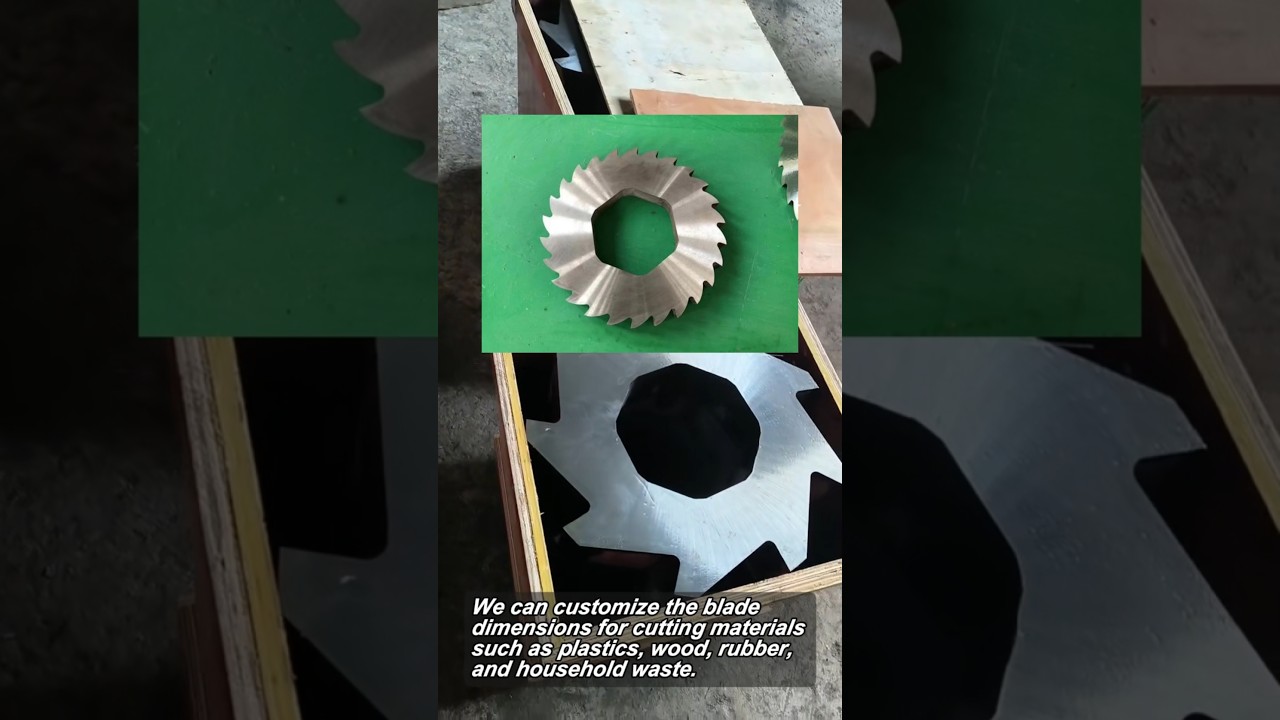

Product Video Demonstration

Product Specifications

| ShengAo H13 Double Shaft Shredder Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

H13 Recycled Plastic Wood Metal Double Shaft Shredder Blade New H13 steel double shaft shredder blades for recycled plastic, wood, and metal. High-performance cutting machine blades offer superior toughness and heat resistance for demanding conditions. | ||||||||||

| Key Specifications | Brand Name ShengAo Type Shredder Blade Material H13 Tool Steel Usage Shred Metal, Plastic, Wood Hardness HRC 56-58 Place of Origin Anhui, China Minimum Order Quantity 10 pcs Surface Finish Ra 0.2 Thickness Tolerance OEM Standard Package Wooden Case | |||||||||

| Quality & Warranty | Quality Control Machinery Test Report: Provided Video Outgoing-Inspection: Provided Warranty & Support 6 Warranty Period: 6 Months H13 Core Components Material: H13 Tool Steel ODM OEM & ODM Support: Supported | |||||||||

| Delivery & Payment | Lead Time Based on Quantity

Lead time starts from order confirmation and deposit received. Payment Terms Payment: 15-25 days Standard Terms | |||||||||

| Customization Options | Customized Logo Minimum Order: 10 pieces Details: As requested Customized Packaging Minimum Order: 10 pieces Details: As requested Graphic Customization Minimum Order: 10 pieces Details: As requested Customization fee may apply based on specific requirements. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our H13 Double Shaft Shredder Blades

The double shaft shredder rotor blades and counter blades form the essential cutting heart of heavy-duty industrial shredders. Engineered for superior performance in the most demanding conditions, these blades work in synchronized pairs to shear and tear through tough materials with exceptional efficiency. Our H13 steel blades are specifically designed for applications requiring high toughness and heat resistance, making them ideal for processing mixed waste streams containing plastic, wood, and metal. Built for durability and maximum uptime, they are the core component that determines shredding efficiency and output quality in recycling operations.

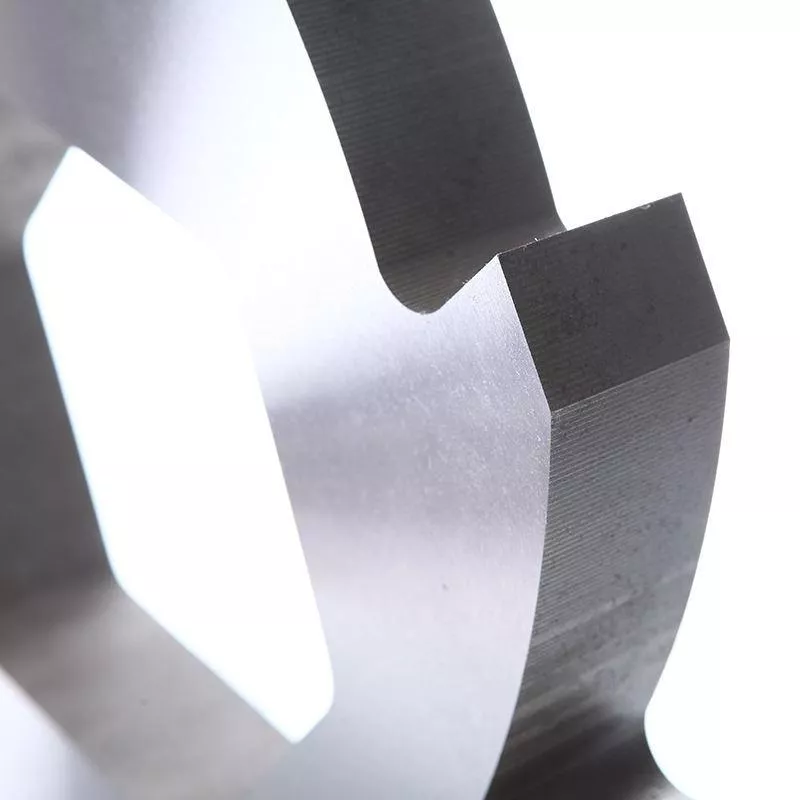

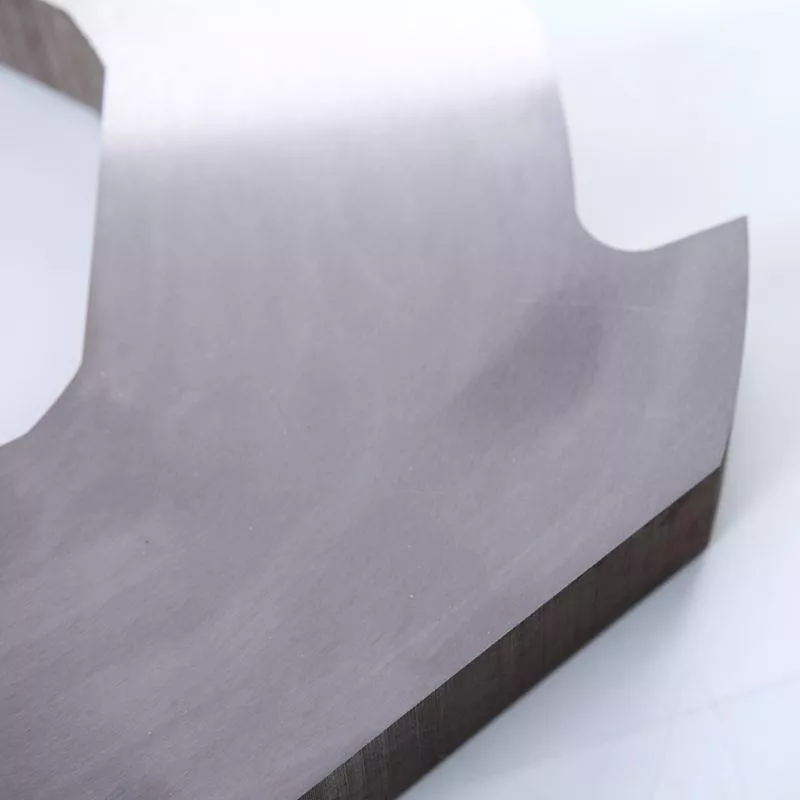

Premium Material & Construction

Our double shaft shredder blades are manufactured from premium H13 hot-work tool steel, a material renowned for its exceptional combination of high toughness, excellent thermal fatigue resistance, and good wear resistance. This steel is heat-treated to achieve an optimal hardness of HRC 56-58, providing the perfect balance between edge retention and impact resistance. Each blade undergoes precision machining to achieve a superior surface finish of Ra 0.2, ensuring smooth operation, minimal friction, and consistent cutting performance. The blades are produced with tight dimensional tolerances to OEM standards, guaranteeing perfect fit and synchronization in dual-shaft systems.

Key Features & Benefits

Designed for extreme durability and high performance, these blades deliver significant operational advantages. The H13 tool steel construction provides outstanding resistance to thermal fatigue, preventing cracking under the high heat generated during continuous shredding of tough materials. Their excellent toughness handles unexpected impacts from metals or hard contaminants without catastrophic failure. The dual-shaft design and precise blade geometry ensure efficient shearing action, resulting in consistent particle size, high throughput, and low energy consumption. This leads to reduced maintenance frequency, lower operating costs, and maximum productivity in your industrial recycling or waste processing facility.

Application Industries & Materials

These high-performance blades are engineered for the toughest size reduction challenges across multiple industries. They excel in shredding mixed recyclables (plastics, wood, light metals), electronic waste (WEEE), industrial plastic lumps and purgings, demolition wood, non-ferrous metal scrap, and bulky municipal solid waste (MSW). Key industries that benefit include metal recycling, plastic recycling facilities, electronic waste processing, wood waste management, and automotive shredding operations. Their versatility makes them an essential component in systems designed for volume reduction, material liberation, and preparation for downstream sorting or processing.

Customization & Quality Assurance

We specialize in providing fully customized double shaft shredder blade solutions to perfectly match your specific machine model, shaft diameter, and material stream. Our comprehensive OEM and ODM services support custom dimensions, hole patterns, cutting edge profiles, and special heat treatment requirements. Quality is guaranteed through both official machinery test reports and our unique video outgoing-inspection for every order, providing documented and visual proof of compliance. Backed by a solid 6-month warranty and packaged securely in wooden cases, these blades are delivered ready for installation, ensuring minimal downtime and reliable long-term performance in your critical shredding operations.

Top 5 Double Shaft Shredder Blade Brands for Heavy-Duty Recycling

Selecting the right blade brand is paramount for the efficiency and longevity of dual-shaft shredders in demanding applications. These manufacturers are recognized globally for their engineering excellence, material technology, and proven performance in processing tough, mixed materials.

ShengAo

A specialist in heavy-duty cutting tools, ShengAo manufactures premium double shaft shredder blades from H13 hot-work tool steel, heat-treated to HRC 56-58. Known for exceptional toughness and thermal fatigue resistance, they are ideal for mixed waste streams containing metal and plastic. With strong OEM/ODM support, comprehensive quality documentation (machinery test reports + video inspection), a 6-month warranty, and efficient 20-day lead times for up to 100 pieces, they offer a reliable and high-performance solution for the most demanding shredding applications.

Vecoplan

The German technology leader in shredding, Vecoplan designs and manufactures robust double shaft shredder blades as integral parts of their high-performance systems. Their blades are engineered for maximum durability, precise cutting geometry, and high throughput in continuous industrial applications, particularly in plastics recycling, wood processing, and waste-to-fuel operations.

SSI Shredding Systems

An American pioneer in industrial shredding, SSI manufactures heavy-duty dual-shaft shredders and their corresponding blades. SSI blades are built for extreme conditions, often using high-alloy steels and specialized hardening processes to handle challenging materials like tires, metals, and industrial waste, focusing on reliability and low cost of ownership.

WEIMA

Another leading German manufacturer, WEIMA produces durable and efficient double shaft shredder blades designed for their machinery. They focus on innovative blade geometries and mounting systems to optimize cutting efficiency, reduce energy consumption, and facilitate easy maintenance, serving the plastics, wood, and waste recycling industries.

Eldan Recycling

A Danish specialist, Eldan provides robust double shaft shredder solutions and blades primarily for the tire and cable recycling industries. Their blades are designed to handle highly abrasive materials and often incorporate wear-resistant features like hard-facing or specialized alloys to extend service life in these challenging applications.

Frequently Asked Questions (FAQs)

Find expert answers to the most common questions about H13 Double Shaft Shredder Blades for heavy-duty recycling applications.