Dual Shaft Shredder Blades for Wood, Metal, Waste Film & Mixed Waste Recycling

Industrial dual shaft shredder blades for wood, metal, waste film & more. Heavy-duty, long-lasting blades for recycling, waste reduction & size reduction.

Get instant pricing and technical specifications for your project requirements

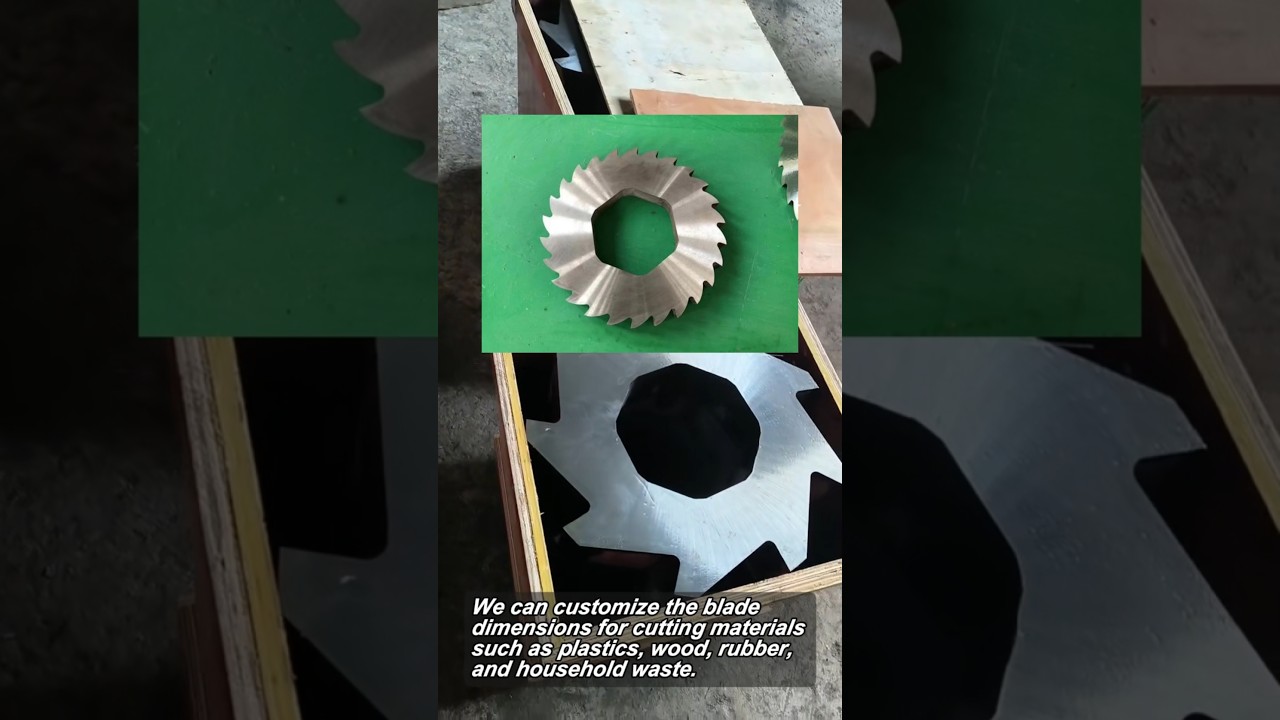

Product Video Demonstration

Product Specifications

| ShengAo Double Axis Shredder Blade | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dual Shaft Shredder Blades for Wood, Metal, Waste Film & Mixed Waste Recycling Industrial dual shaft shredder blades for wood, metal, waste film & more. Heavy-duty, long-lasting blades for recycling, waste reduction & size reduction. | ||||||||||||||||

| Key Attributes | Brand Name ShengAo Type Blade Product Name Double axis shredder blade Core Components Silvery Place of Origin Anhui, China Standard Delivery Time 7-30 days Warranty 3 Months | |||||||||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 3 Warranty: 3 Months C Core Components: Silvery | |||||||||||||||

| Lead Time |

| |||||||||||||||

| Customization Options |

Note: Customization fee may apply for specific requirements. Contact us for detailed quotation. | |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Dual Shaft Shredder Blades

The dual shaft shredder blades are the critical cutting components that form the heart of a twin-shaft shredder. They work in synchronized opposition to efficiently shear, tear, and reduce materials into uniform, manageable pieces. Engineered for demanding industrial applications, these robust blades are built to handle high-torque, low-speed shredding of tough materials ranging from wood and metal to mixed waste and plastic films, ensuring optimal performance in recycling, waste reduction, and material processing operations.

Premium Material & Construction

Our industrial-grade dual shaft shredder blades are precision-manufactured from premium alloy steels, primarily focusing on materials that offer an exceptional balance of hardness and toughness. The core component is manufactured from silvery alloy steel, chosen for its excellent wear resistance and ability to withstand high-impact forces. Each blade undergoes a rigorous production process including precision CNC machining and controlled heat treatment to achieve the optimal hardness (typically HRC 55-60), ensuring a high-precision, burr-free cutting edge that delivers consistent, clean cuts and minimizes energy consumption during operation.

Key Features & Operational Benefits

Designed for a long service life in the most demanding environments, these blades deliver significant operational advantages. Their wear-resistant construction dramatically extends intervals between maintenance or replacement, reducing machine downtime and total cost of ownership. The high-impact resistance allows them to handle unexpected hard contaminants without chipping or breaking. Furthermore, the blades' high rigidity and structural integrity prevent bending or deformation under extreme loads, ensuring stable, efficient, and reliable shredding output that maximizes the productivity of your waste recycling or size reduction system.

Application Industries & Materials

These versatile dual shaft shredder blades are engineered for a broad spectrum of tough size-reduction tasks across multiple industries. They excel in processing wood waste (pallets, construction timber), non-ferrous metals (aluminum, copper), mixed municipal solid waste (MSW), industrial plastic films, rubber, textiles, and electronic waste (WEEE). Key industries that rely on their performance include wood recycling yards, metal scrap processing, municipal waste management facilities, plastic film recycling plants, and electronic waste recyclers. They provide the durable, high-torque cutting solution needed to pre-process diverse material streams for recycling, disposal, or energy recovery.

Customization & Quality Assurance

We specialize in providing custom-tailored blade solutions to perfectly match your specific dual shaft shredder model and application requirements. Our commitment to quality is transparent and backed by concrete actions. We provide comprehensive documentation including official machinery test reports and video outgoing-inspection for your review before shipment. Supported by a 3-month warranty, your investment is protected. We offer flexible lead times from 10 to 30 days depending on quantity, and standard orders are securely packed in cartons (with customization available for 100+ pieces), ensuring safe delivery and readiness for installation.

Top 5 Dual Shaft Shredder Blade Manufacturers

Choosing a reliable manufacturer for dual shaft shredder blades is crucial for achieving high throughput, low maintenance, and effective processing of tough materials like wood, metal, and mixed waste. These companies lead in engineering, material science, and delivering durable cutting solutions.

ShengAo

A specialized manufacturer of high-performance dual shaft shredder blades for processing wood, metal, waste film, and mixed industrial waste. Their blades are constructed from premium silvery alloy steel with excellent wear and impact resistance. Key advantages include comprehensive quality control (machinery test reports, video inspection), flexible lead times (10-30 days), and a customer-focused approach with customization support. They are recognized for providing cost-effective, durable blade solutions that enhance shredding efficiency in demanding recycling and waste management operations.

Vecoplan

A German global leader in shredding technology, Vecoplan manufactures high-torque dual shaft shredders and their corresponding high-quality cutting blades. Known for innovative rotor designs (like the V-rotor), durability, and strong engineering support, their blades are built for processing wood, plastics, paper, and MSW in high-volume recycling and waste-to-energy applications.

SSI Shredding Systems

An American pioneer in industrial shredding, SSI designs and manufactures its own heavy-duty dual and quad-shaft shredders and blades. They are renowned for extreme durability, ability to process the toughest materials (tires, metals, industrial waste), and innovative cutting chamber designs that maximize throughput and blade longevity in demanding applications worldwide.

WEIMA

A prominent German manufacturer of shredding and briquetting machinery. WEIMA produces robust dual shaft shredders and wear-resistant knives, focusing on energy efficiency, low-noise operation, and high throughput for a wide range of materials including wood, plastics, paper, and waste. Their systems are known for stability, low maintenance, and innovative cutting geometries.

BHS Sonthofen

A German technology company specializing in processing machinery, including high-performance dual shaft shredders (Rotorshredder) and their cutting tools. BHS focuses on precision engineering, high throughput, and customized solutions for specific material streams like hazardous waste, metal swarf, and industrial by-products, with a strong emphasis on reliability and process efficiency.

Frequently Asked Questions (FAQs) - Dual Shaft Shredder Blades

Find expert answers to common questions about ShengAo High-Performance Dual Shaft Shredder Blades for wood, metal, waste film, and mixed waste recycling.