Double Axis Custom OEM Shredder Blades | High Hardness for Metal & Plastic

Premium custom OEM double shaft shredder blades. Engineered for extreme hardness to crush scrap metal, aluminum & plastic. Durable industrial blades for heavy-duty recycling.

Get instant pricing and technical specifications for your project requirements

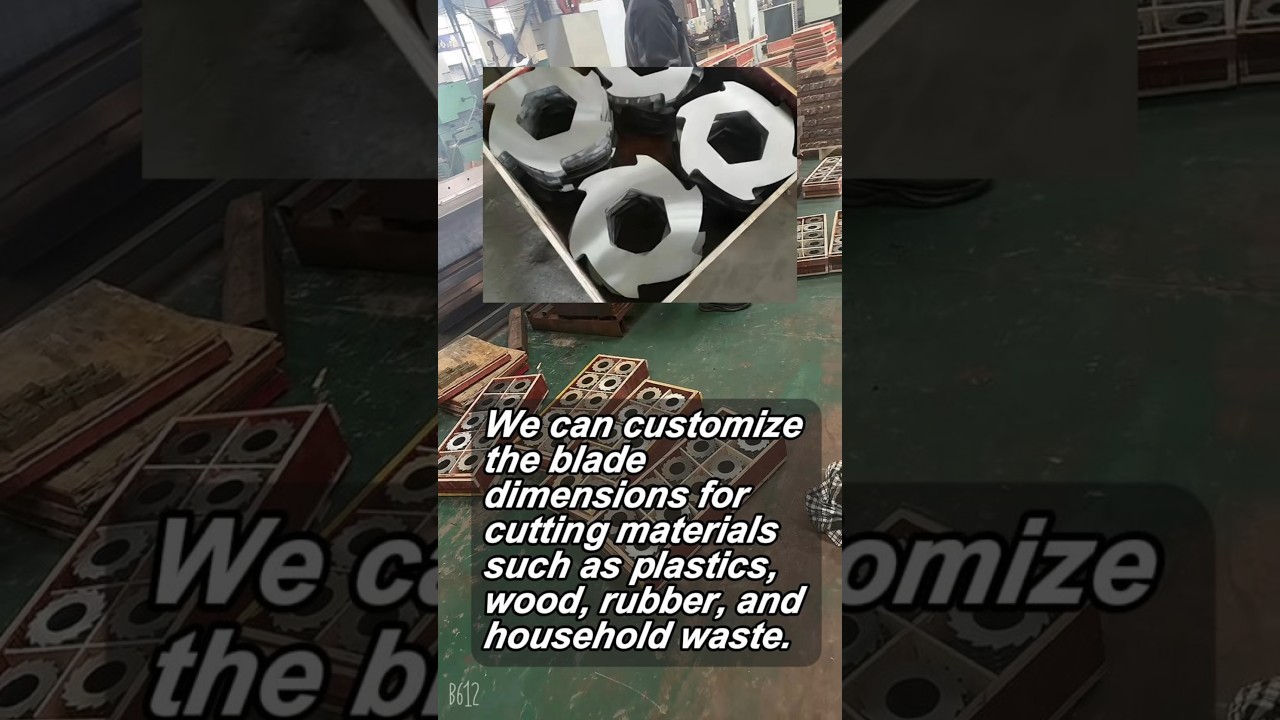

Product Video Demonstration

Product Specifications

| Double Axis Custom OEM Shredder Blades | High Hardness for Metal & Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Premium Custom OEM Double Shaft Shredder Blades Engineered for extreme hardness to crush scrap metal, aluminum & plastic. Durable industrial blades for heavy-duty recycling. | ||||||||||

| Key Attributes | Material Steel Spare Parts Type MACHINE PARTS Weight (KG) 30 Brand Name ShengAo Place of Origin Anhui, China Material Options SKD11 D2 H13 HSS etc | |||||||||

| Key Selling Points | Competitive Price Long Service Life Easy To Operate High-Accuracy High Safety Level | |||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty 1.5 Warranty Period: 1.5 Year | |||||||||

| Lead Time |

Lead time starts from order confirmation and deposit received. | |||||||||

| Customization Options |

Custom sizes, materials, and other specifications available upon request. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Double Axis Shredder Blades

Our Double Axis (Shaft) Shredder Blades represent the pinnacle of cutting technology for heavy-duty industrial recycling. As the core machine parts of a dual-rotor shredding system, these intermeshing blades work in tandem to tear, shear, and crush the toughest materials. Engineered for extreme hardness and durability, they are custom-made to deliver maximum performance, longevity, and efficiency in the most demanding scrap metal and plastic processing environments.

Premium Material & Construction

We manufacture our double shaft shredder blades from a range of premium, high-hardness alloy steels to suit specific applications. Our standard material options include SKD11, D2, H13, and HSS (High-Speed Steel). Each of these materials is selected for its exceptional properties: SKD11 and D2 offer outstanding wear resistance and toughness for metal shredding, H13 provides superior thermal fatigue and impact resistance, while HSS ensures excellent edge retention. Every blade, with a substantial weight of approximately 30kg depending on size, undergoes precision forging, computer-controlled heat treatment, and CNC grinding to achieve a high-accuracy, burr-free cutting profile that ensures smooth, intermeshing operation and consistent cutting force.

Key Features & Operational Benefits

Designed for a long service life and high safety level, these blades excel in extreme environments. Their key selling points translate into direct operational benefits: High-Accuracy manufacturing ensures perfect blade alignment and balance, minimizing vibration and wear on the shredder's gearbox and bearings. The Competitive Price offers an excellent return on investment. The robust design makes them Easy To Operate and maintain within the system. Most importantly, the combination of premium materials and precision engineering provides exceptional wear and impact resistance, significantly reducing unplanned downtime for blade changes and ensuring stable, high-volume output in heavy-duty recycling operations.

Application Industries & Materials

These industrial blades are purpose-built for the most challenging size reduction tasks. They are highly effective in processing a vast range of materials, including scrap metal (ferrous and non-ferrous), aluminum profiles and castings, mixed metals, end-of-life vehicles (ELV), WEEE (e-waste), tires, heavy-duty plastics, and industrial waste. The double-shaft design is particularly suited for high-torque, low-speed shredding of bulky, dense, or composite materials. Industries that rely on these durable blades include metal recycling yards, automotive shredders, electronic waste recycling plants, municipal solid waste (MSW) processing facilities, and industrial demolition. They are the workhorse of any operation requiring primary reduction of tough, voluminous feedstocks.

Customization & Comprehensive Quality Assurance

We specialize in providing fully custom OEM double shaft shredder blade solutions. Every aspect can be tailored: dimensions, knife geometry (hook, claw, or staggered design), material grade (SKD11, D2, H13, HSS), and mounting specifications to fit your specific dual-shaft shredder model. Our commitment to quality is unwavering, demonstrated through provided video outgoing-inspection and official machinery test reports for full traceability and confidence. Each blade is backed by an exceptional 1.5-year warranty, reflecting our confidence in their durability. Packed securely to prevent damage in transit, these premium spare parts arrive ready for installation, ensuring your recycling line quickly returns to peak productivity.

Top 5 Double Shaft Shredder Blade Manufacturers

Selecting the right manufacturer for double shaft shredder blades is critical for durability, uptime, and total cost of ownership in heavy-duty metal and waste recycling. These companies lead in material science, engineering robustness, and providing high-performance solutions.

ShengAo

A leading OEM manufacturer specializing in high-hardness, custom double shaft shredder blades for demanding metal and plastic recycling applications. Their blades are made from premium steels like SKD11, D2, H13, and HSS, with weights around 30kg, engineered for extreme durability. Key advantages include a strong focus on heavy-duty scrap processing, full OEM customization, an industry-leading 1.5-year warranty, and comprehensive quality control with video and machinery test reports. They offer a compelling blend of competitive pricing, high-accuracy, and long service life.

Vecoplan

A German global pioneer in shredding technology. Vecoplan engineers and manufactures robust double shaft shredders and their corresponding high-performance blades for processing wood, plastics, MSW, and industrial waste. Known for innovative cutting geometries, durability, and strong technical support, they provide comprehensive solutions for high-volume processing and are a benchmark for quality in the waste recycling industry.

SSI Shredding Systems

An American industry leader with a global reputation for building extremely durable and reliable shredders for the toughest applications, including metal turnings, tires, and mixed solid waste. Their double shaft blades are engineered for maximum uptime, impact resistance, and longevity in continuous, demanding operations, backed by extensive application engineering expertise.

WEIMA

A prominent German manufacturer of shredding and briquetting machinery. WEIMA produces robust double shaft shredders and blades with a focus on energy efficiency, low-wear operation, and high throughput for materials like plastics, wood, paper, and industrial waste. Their systems are known for stability, low maintenance requirements, and consistent performance.

Forrec

An Italian manufacturer specializing in heavy-duty shredding systems for industrial and municipal solid waste, including bulky metals and mixed materials. Forrec's double shaft blades are built for maximum impact resistance, uptime, and throughput in large-scale recycling and waste management operations where processing volume and equipment durability are paramount.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Double Axis Shredder Blades for heavy-duty metal and industrial recycling.