Cutting Blades Double Shaft Shredder Machine Blades Plastic Grinding

Precision cutting blades for double shaft shredder machines and plastic grinding. Optimized for efficient material shredding and granulation, ensuring smooth operation and consistent particle size.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| Cutting Blades for Double Shaft Shredder Machine | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Round Blade - Precision Cutting Blades for Plastic Grinding Precision cutting blades for double shaft shredder machines and plastic grinding. Optimized for efficient material shredding and granulation, ensuring smooth operation and consistent particle size. | ||||||||||

| Key Attributes & Specifications | Primary Specifications Product Name Round Blade Type 350*32*3 Type Size 350*32*3 Texture of Material Cr12MoV Core Components Material Quality Assurance Machinery test report: Provided Video outgoing-inspection: Provided 3 Warranty: 3 Months | |||||||||

| Lead Time | Production Lead Time Based on Order Quantity

Lead time starts from order confirmation and deposit received. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Double Shaft Shredder Cutting Blades

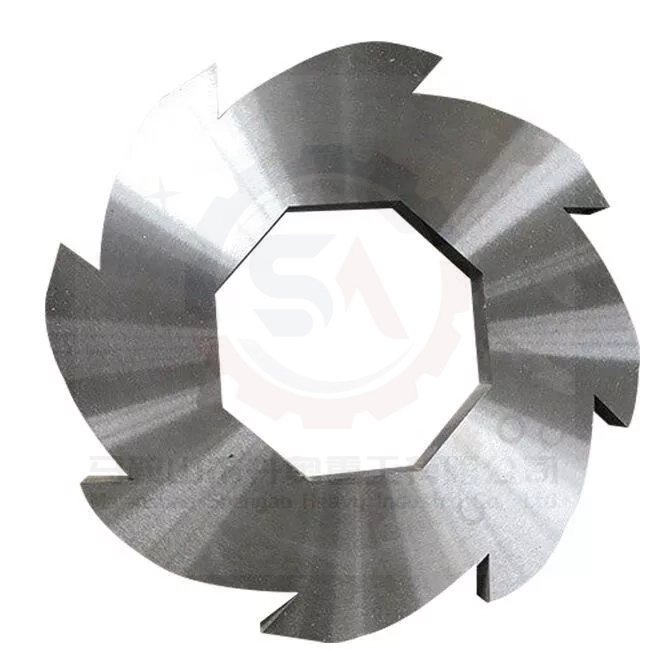

The round cutting blades for double shaft shredder machines are precision-engineered components designed specifically for plastic grinding and efficient material size reduction. These blades work in synchronized pairs on intermeshing counter-rotating shafts to create a powerful shearing action that efficiently processes tough materials. Engineered with dimensions of 350*32*3mm, these blades are optimized for consistent particle size output, smooth operation, and reliable performance in demanding shredding applications. As the core cutting component of dual-shaft shredders, they ensure efficient material processing for recycling and waste management operations.

Premium Material & Construction

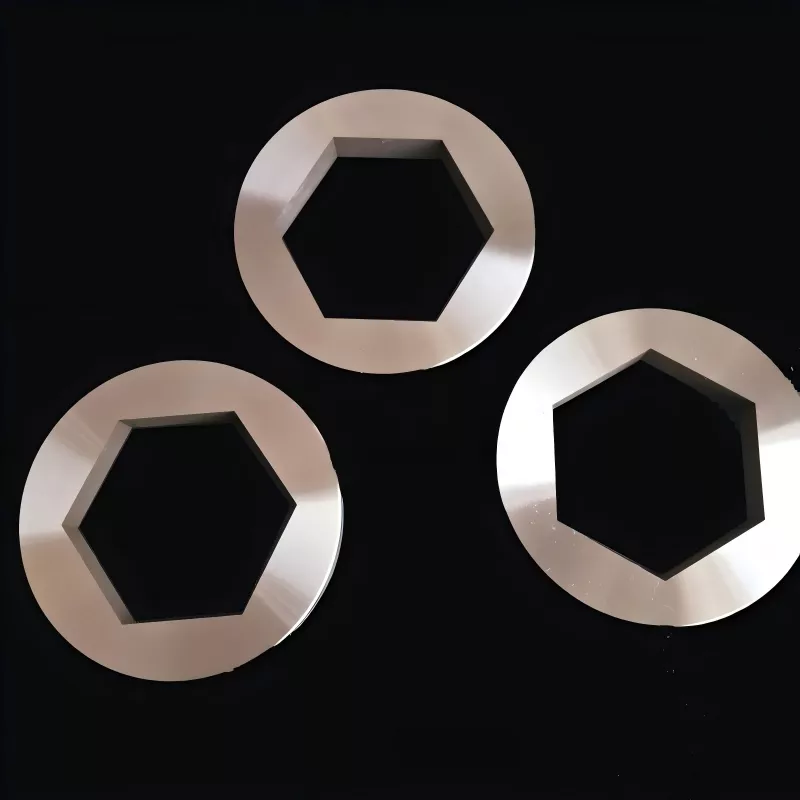

Our double shaft shredder blades are manufactured from premium Cr12MoV tool steel, a high-carbon, high-chromium alloy steel known for its excellent wear resistance, good toughness, and high hardness after heat treatment. This material composition provides superior performance in demanding plastic grinding applications where resistance to abrasion and edge retention are critical. Each blade is precision-machined to exact dimensions of 350mm diameter, 32mm thickness, and 3mm cutting edge, ensuring perfect fit and synchronization in dual-shaft systems. The blades undergo specialized heat treatment processes to achieve optimal hardness and durability, followed by precision grinding to create sharp, consistent cutting edges that deliver reliable performance throughout their service life.

Key Features & Benefits

Designed for maximum efficiency and durability, these cutting blades offer significant operational advantages. The Cr12MoV material construction provides exceptional wear resistance, extending blade life and reducing maintenance frequency in continuous plastic grinding operations. The round blade design and precise dimensions ensure optimal intermeshing with counter-rotating blades, creating efficient shearing action that produces consistent particle sizes. This results in higher throughput, lower energy consumption, and reduced operating costs. The blades' high precision manufacturing minimizes vibration and noise during operation, contributing to smoother machine performance and extended equipment life. Their robust design handles tough materials effectively while maintaining cutting efficiency over extended periods.

Application Industries & Materials

These precision cutting blades are specifically designed for double shaft shredder machines used in plastic grinding and size reduction applications. They excel in processing various plastic materials including PET bottles, HDPE containers, PP packaging, PVC profiles, plastic films, and engineering plastics. Beyond plastics, they effectively handle rubber materials, textiles, paper products, and light composite materials. Industries that benefit from these blades include plastic recycling facilities, waste management companies, material recovery operations, and manufacturing plants with in-house scrap processing needs. These blades are ideal for applications requiring primary size reduction of bulky materials before further processing in granulators or other downstream equipment, making them essential components in comprehensive recycling and waste processing systems.

Customization & Quality Assurance

We specialize in providing precision cutting blade solutions tailored to specific double shaft shredder models and applications. While our standard offering includes the 350*32*3mm round blades in Cr12MoV material, we can customize dimensions, materials, and specifications to meet unique operational requirements. Our commitment to quality is demonstrated through comprehensive documentation including official machinery test reports and video outgoing-inspection for every order, providing verified performance data and visual confirmation of quality. Backed by a 3-month warranty, these blades represent reliable cutting solutions for demanding applications. With efficient lead times (15 days for orders of 1-20 pieces) and responsive customer support, we ensure timely delivery and ongoing technical assistance for optimal integration and performance in your shredding operations.

Top 5 Cutting Blade Brands for Double Shaft Shredders

Selecting high-quality cutting blades is essential for the efficiency and reliability of double shaft shredders. These manufacturers are recognized for their material expertise, precision engineering, and proven performance in plastic grinding and size reduction applications.

ShengAo

A leading manufacturer specializing in precision cutting blades for double shaft shredders. Their 350*32*3mm round blades are made from premium Cr12MoV tool steel, offering excellent wear resistance and durability for plastic grinding applications. Known for comprehensive quality assurance including machinery test reports and video inspections, with a 3-month warranty and efficient 15-day lead times for small to medium orders (1-20 pieces), making them a reliable choice for recycling operations.

Vecoplan

The German engineering leader offers high-quality cutting blades for their double shaft shredders. Vecoplan blades are designed for precision cutting, optimal intermeshing, and long service life in continuous industrial recycling applications, with specialized geometries for different material streams and high-volume operations.

SSI Shredding Systems

An American manufacturer of heavy-duty industrial shredders, SSI produces robust cutting blades for their dual-shaft systems. Their blades are designed for extreme conditions and challenging materials, with a focus on durability, high torque handling, and reliable performance in demanding recycling and waste processing environments.

WEIMA

Another German manufacturer known for efficient size reduction technology, WEIMA produces durable cutting blades for their double shaft shredders. Their blades are designed for energy efficiency, easy maintenance, and consistent performance in plastic and waste processing applications, with various designs optimized for different material types.

Zerma

A specialist in size reduction equipment, Zerma manufactures robust cutting blades for their double shaft shredders with a focus on longevity and cost-effectiveness. Their blade designs often feature optimized cutting geometries and materials to maximize service life and minimize total cost of ownership in continuous recycling operations.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about Double Shaft Shredder Cutting Blades for plastic grinding and size reduction applications.