Customization High Hardness Shredder Machine Blade Alloy Steel Plastic Single Shaft Shredder Durable Blades And Knives

Custom high-hardness alloy steel shredder blades for single shaft machines. Perfect for plastic recycling. Engineered for exceptional durability, wear resistance, and prolonged service life.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo High Rigidity Single Shaft Shredder Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Custom High-Hardness Alloy Steel Shredder Blades Custom high-hardness alloy steel shredder blades for single shaft machines. Perfect for plastic recycling. Engineered for exceptional durability, wear resistance, and prolonged service life. | ||||||||||

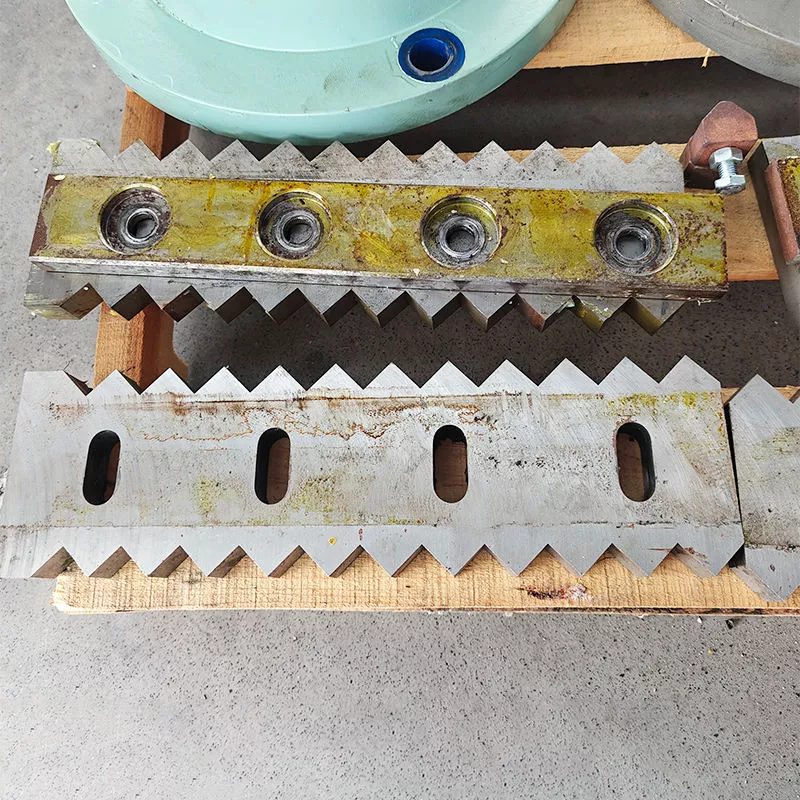

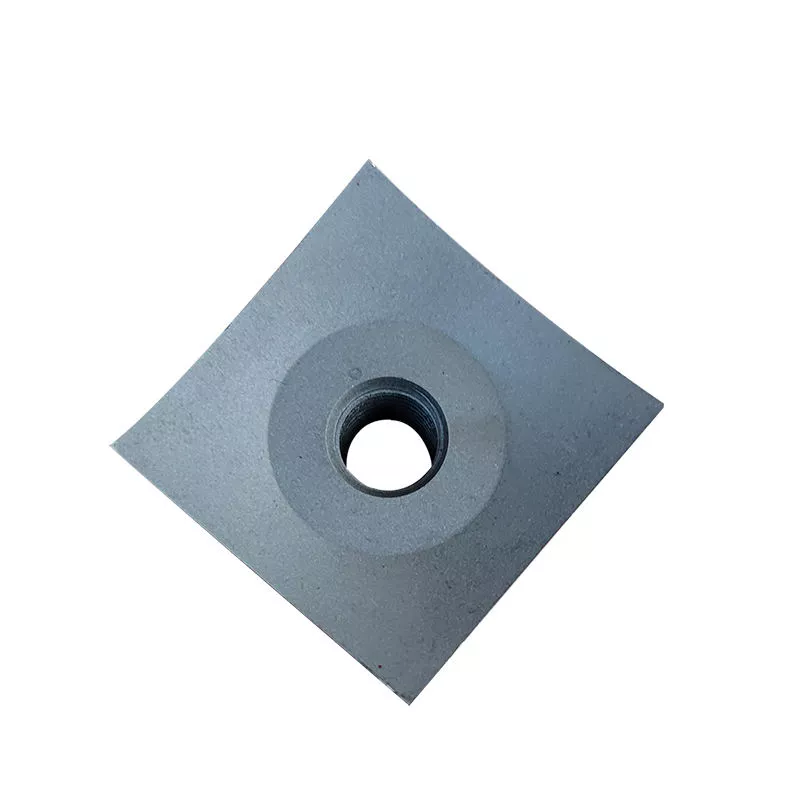

| Product Specifications | Brand Name ShengAo Place of Origin Anhui, China Type Rotor Blade, Fixed Blade Material DC53; Customizable Application Plastic, Textile, Film, etc For What Machine Single Shaft Shredder Features Durable; Wear resistance; Impact resistance Surface High precision surface, burr-free Weight 1 KG Service Tailor-made / Customization Supported | |||||||||

| Quality Assurance | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components N/A Warranty: Unavailable DC53 Core Material: DC53 Alloy Steel | |||||||||

| Delivery Information | Minimum Order Quantity (MOQ) 20 Pcs Packing Wooden Case Lead Time Based on Quantity

Lead time starts from order confirmation and deposit received. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

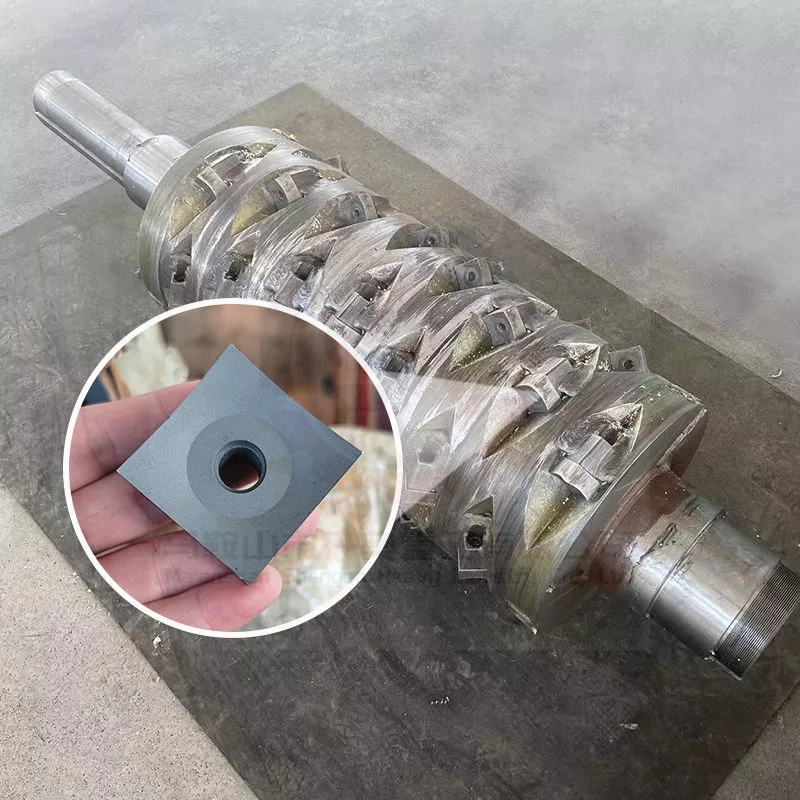

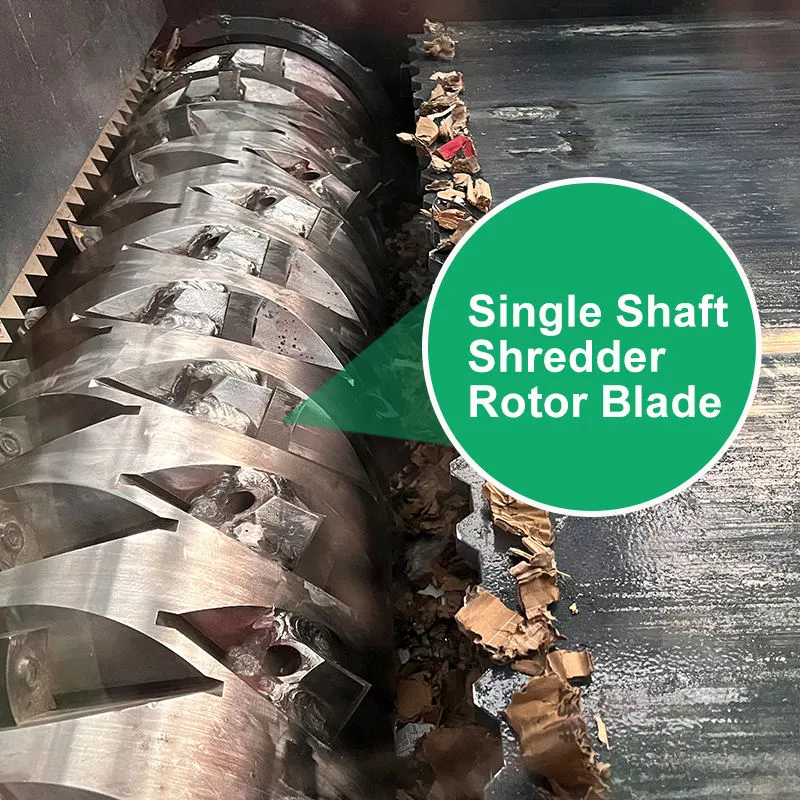

The ShengAo High Rigidity Single Shaft Shredder Blades (including rotor and fixed blades) are the core cutting components of single shaft shredding systems. Designed for maximum performance and durability, these blades are engineered to withstand the extreme forces encountered in industrial shredding applications. They are used across various industries to efficiently reduce the size of materials for easier handling, recycling, disposal, or further processing. Our custom-made blades, with high-precision surfaces, ensure optimal cutting efficiency and extended service life in the most demanding environments.

Premium Material & Construction

Our high rigidity shredder blades are primarily manufactured from DC53 High-Speed Steel (HSS), a superior Japanese-grade cold work tool steel known for its exceptional combination of wear resistance, toughness, and high hardness. This material is further customizable to D2, SKD-11, or other alloy steels to suit specific operational needs and material streams. The advanced heat treatment process ensures a hardness level that perfectly balances edge retention with impact resistance. Each blade features a high-precision, burr-free surface, achieved through precision grinding, which guarantees smooth operation, minimal friction, and consistent cutting performance throughout its lifecycle.

Key Features & Benefits

Engineered for a long service life, these blades excel in demanding recycling and waste processing environments. The key benefit is exceptional durability, which significantly reduces the frequency and cost of blade replacements. Their high wear resistance maintains sharp cutting edges longer, ensuring consistent shred size and throughput. The impact-resistant design, inherent in DC53 steel, allows the blades to handle unexpected hard contaminants without catastrophic failure. Most importantly, the high rigidity prevents bending, flexing, or deformation under heavy and variable loads, ensuring stable, efficient, and reliable shredding output over extended operational periods.

Application Industries & Materials

These versatile single shaft shredder blades are perfect for a wide range of size reduction tasks. They are highly effective in processing plastics (including PET bottles, HDPE lumps, films, and hard plastics), textiles and fabrics, rubber, paper and cardboard, non-ferrous metal scraps, and other recyclable or waste materials. Key industries that rely on our blades include plastic recycling plants, waste management facilities, textile processing units, manufacturing plants with scrap handling needs, and electronic waste (e-waste) recycling operations. They provide a reliable and cost-effective solution for converting bulky waste into manageable shreds.

Customization & Quality Assurance

We specialize in providing fully customized blade solutions. From exact dimensions (length, width, thickness, bore size), blade geometry (hook angle, cutting edge design), to material specifications (DC53, D2, etc.), we tailor every aspect to fit your specific single shaft shredder model (like Vecoplan, Weima, Forrec, etc.) and the unique composition of your material stream. Our unwavering commitment to quality is demonstrated through comprehensive video outgoing-inspection (showing you the product before shipment) and official machinery test reports for material verification and hardness certification. Each set of blades is securely packed in robust wooden cases to ensure they arrive in perfect condition, ready for immediate installation and peak performance.

Top 5 Industrial Shredder Machine Blade Brands

The performance and longevity of your shredder heavily depend on the quality of its blades. Here are the leading manufacturers globally recognized for their expertise in producing durable and high-performance shredder blades.

ShengAo

A premier manufacturer and global supplier specializing in custom high-speed steel and alloy steel shredder blades. ShengAo excels in producing high-rigidity rotor and fixed blades for single and double shaft shredders, using premium materials like DC53, D2, and SKD-11. Renowned for exceptional quality control, full customization capabilities, and providing cost-effective alternatives to OEM parts for all major shredder brands worldwide.

Vecoplan

A German engineering leader in shredding technology, Vecoplan manufactures both high-performance shredders and the corresponding OEM replacement blades. Their blades are known for precision engineering, optimal cutting geometry tailored to specific material types, and the use of high-grade steels, often with specialized coatings for enhanced wear life in demanding recycling applications.

WEIMA

Another prominent German manufacturer, WEIMA is renowned for its robust shredding and briquetting machinery. They produce original spare parts, including durable shredder blades designed for perfect compatibility with their machines. WEIMA blades are valued for their consistent quality, long service life in plastic and wood recycling, and designs that maximize energy efficiency and cutting performance.

Forrec

An Italian specialist in industrial shredding systems for waste processing and recycling. Forrec manufactures heavy-duty shredders and their proprietary blades, engineered for high torque and extreme impact resistance. Their blades are particularly well-suited for challenging applications like tire shredding, metal recycling, and processing of bulky industrial waste.

SSI Shredding Systems

A U.S.-based pioneer in shredding technology, SSI designs and manufactures powerful, application-specific shredders. They produce high-quality rotary shear blades that are integral to their machine's performance, known for durability in continuous operation processing municipal solid waste (MSW), electronic waste, and secure document destruction.

Frequently Asked Questions (FAQs)

Find quick answers to common technical and commercial questions about our DC53 Single Shaft Shredder Blades.