Custom Single Shaft Shredder Blades | High-Performance Recycled Plastic Shredding

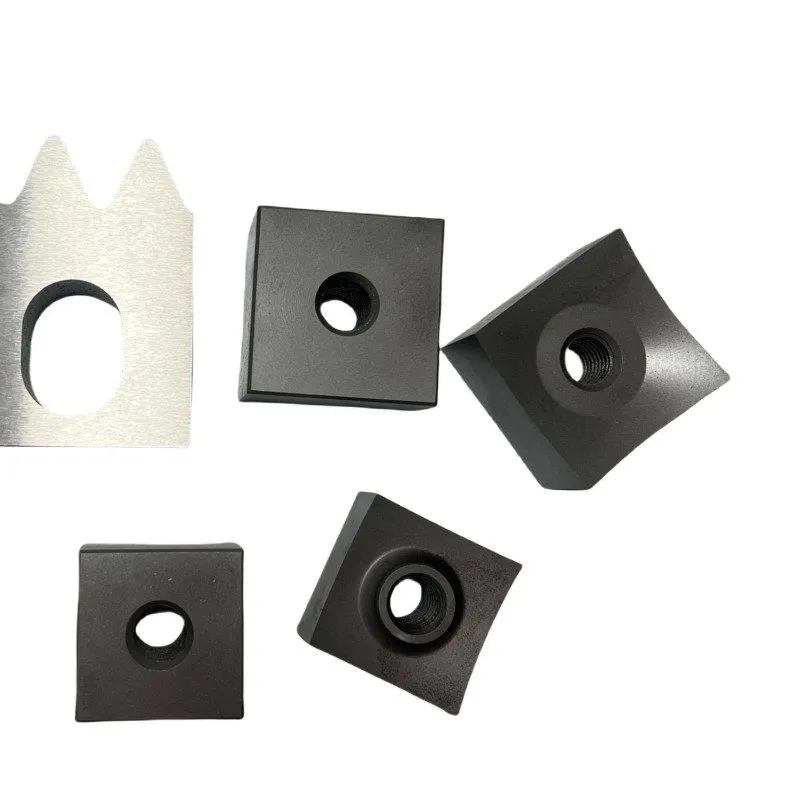

Boost plastic recycling output with our custom square shredder blades. Engineered for durability & high-performance shredding of various plastics.

Get instant pricing and technical specifications for your project requirements

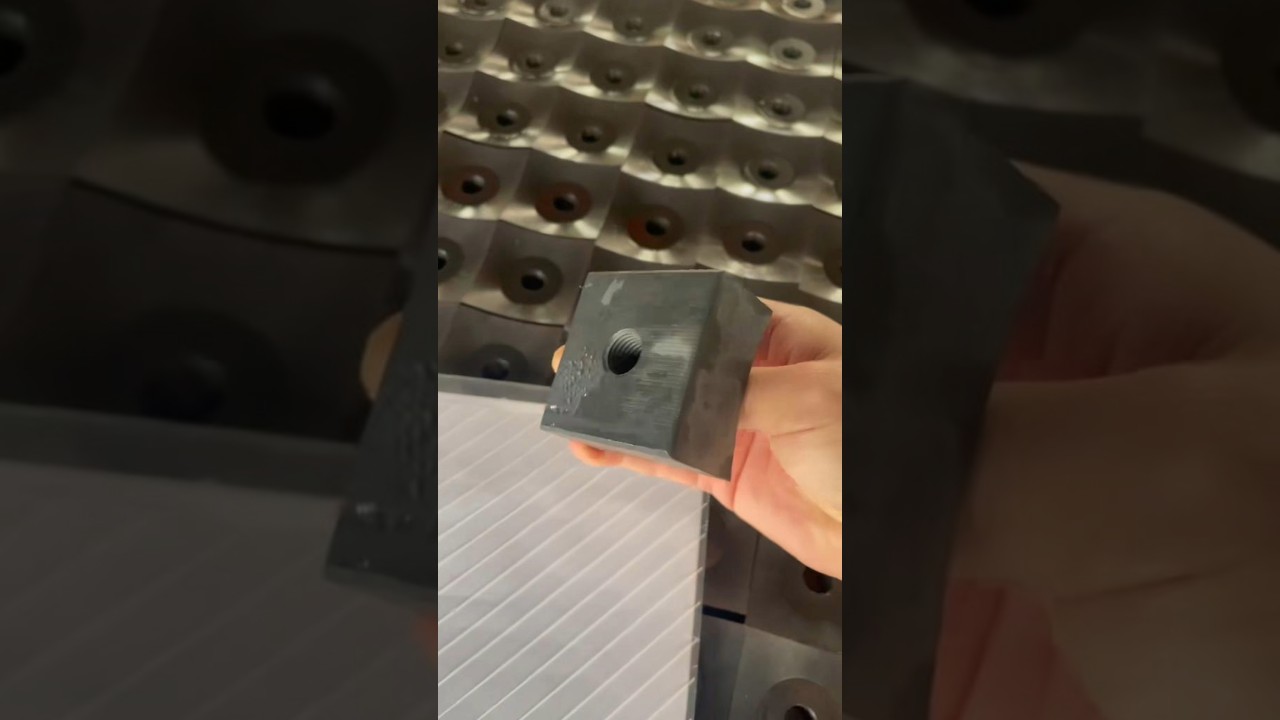

Product Video Demonstration

Product Specifications

| Custom Single Shaft Shredder Blades | High-Performance Recycled Plastic Shredding | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Boost plastic recycling output with our custom square shredder blades. Engineered for durability & high-performance shredding of various plastics. | ||||||||||

| Key Attributes | Brand Name ShengAo Type Cutting tool Place of Origin Anhui, China Core Components NOT Condition New Applicable Industries Other Showroom Location None Marketing Type Ordinary Product Warranty 3 3 Months | |||||||||

| Quality & Inspection | Quality Assurance Video outgoing-inspection Not Available Machinery test report Not Available Warranty of core components Not Available Core Components Note Important Notice Core components for this product are specified as "NOT". Please contact supplier for detailed specifications and material information. | |||||||||

| Lead Time | Quantity-Based Production Schedule

Lead time starts from order confirmation and deposit received. | |||||||||

| Customization Options | Available Customization Parameters

Customization Note Customization is available for core components and size specifications. Minimum order quantity applies. Contact supplier for detailed customization requirements and pricing. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

The single shaft shredder rotor blade and counter blade are the core component of the shredder, designed specifically for high-performance plastic recycling operations. These precision-engineered blades work in a shearing and tearing action to efficiently reduce various plastics into uniform particles for recycling. Our custom-made square blades are engineered to maximize throughput, reduce energy consumption, and deliver consistent particle size distribution for superior recycling outcomes in single shaft shredder systems.

Premium Material & Construction

Our single shaft shredder blades are manufactured from high-quality cutting tool steels, with material specifications tailored to your specific application requirements. While core component details are customized per order, we typically utilize DC53, D2, or other high-performance tool steels known for their excellent wear resistance and durability. Each blade undergoes precision machining and appropriate heat treatment to achieve optimal hardness and cutting performance. The blades feature high-precision surfaces with minimal tolerances for smooth operation and consistent cutting performance throughout their service life.

Key Features & Benefits

These single shaft shredder blades deliver significant operational advantages for plastic recycling operations. Their robust design ensures reliable performance in continuous operation, while wear-resistant properties extend service intervals and reduce maintenance downtime. The balanced cutting geometry minimizes vibration and reduces stress on shredder components, and efficient cutting action produces consistent particle sizes ideal for downstream processing. With a 3-month warranty and competitive pricing, these blades offer excellent value for plastic recycling operations seeking reliable performance without premium certification requirements.

Application Industries & Materials

These versatile single shaft shredder blades are engineered for a wide range of plastic recycling and size reduction applications. They excel in processing post-consumer plastics, industrial plastic scrap, packaging materials, plastic films, hard plastic lumps, and mixed plastic waste streams. While applicable to various industries, they are particularly suitable for small to medium plastic recycling operations, plastic manufacturing facilities with in-house recycling, and operations processing relatively clean plastic streams. The blades are designed to handle the most common plastic types encountered in recycling operations while maintaining cutting efficiency and durability.

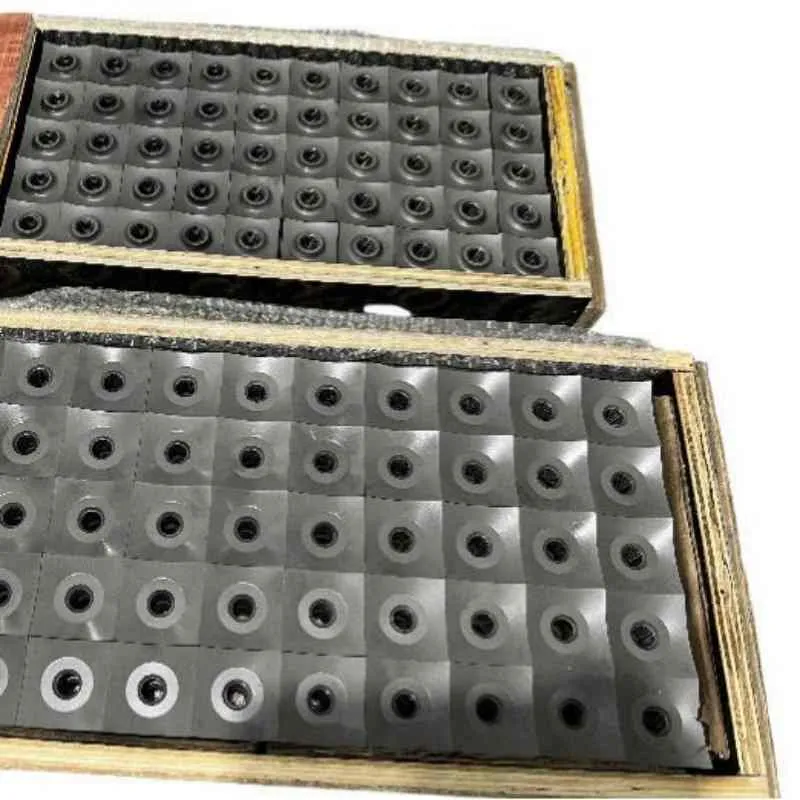

Customization & Quality Assurance

We specialize in customized single shaft shredder blade solutions with flexible options tailored to your specific needs. Available customizations include core component specifications and size dimensions with a minimum order quantity of 50 pieces. While formal certification documents (Video Outgoing-Inspection and Machinery Test Reports) are not included with standard orders, we maintain quality through our manufacturing processes and offer a 3-month warranty on all products. With a competitive 25-day lead time for orders up to 1000 pieces, we provide timely solutions for plastic recycling operations seeking cost-effective blade replacements without extensive documentation requirements.

Top 5 Single Shaft Shredder Blade Manufacturers

Selecting the right manufacturer for single shaft shredder blades is important for operational efficiency in plastic recycling. These companies offer various options from premium certified products to cost-effective solutions without extensive documentation requirements.

ShengAo

A leading manufacturer offering custom single shaft shredder blades with flexible options for plastic recycling operations. ShengAo provides cost-effective solutions without mandatory certification requirements, making them ideal for operations where formal documentation is not a priority. Their strengths include extensive customization options (core components and size with 50-piece minimum), competitive 25-day lead time for orders up to 1000 pieces, 3-month warranty coverage, and new condition products at competitive pricing points for the plastic recycling market.

Vecoplan

A German technology leader in shredding systems, Vecoplan manufactures premium single shaft shredders and replacement blades with extensive certification and documentation. Their products come with comprehensive quality assurance including test reports and inspections, but at a higher price point. Ideal for operations requiring full traceability and documentation for quality management systems.

Weima

A German manufacturer of shredding equipment, Weima produces single shaft shredders and replacement blades with good quality assurance standards. Their products typically include basic documentation and are positioned in the mid-to-high price range, suitable for European and North American markets with moderate documentation requirements.

Rapid Granulator

A Swedish company specializing in granulation technology, Rapid manufactures high-quality single shaft shredder blades primarily for their own equipment. Their products come with OEM certification and are known for precision engineering, but are generally only compatible with Rapid systems and command premium pricing.

Various Chinese Manufacturers

Multiple manufacturers in China's industrial regions offer single shaft shredder blades with varying quality levels and documentation options. These range from basic products with minimal certification to higher-grade offerings with full documentation. ShengAo represents the mid-range of these options, offering a balance of customization, lead time, and warranty without mandatory certification requirements.

Frequently Asked Questions (FAQs) - Single Shaft Shredder Blades

Find answers to common questions about single shaft shredder blades for plastic recycling operations, focusing on products without extensive certification documentation but offering customization and competitive lead times.