Custom Single Shaft Shredder Blades for Efficiency

Custom Single Shaft Shredder Blades for Efficiency

Table of Contents

- Beyond One-Size-Fits-All: The Strategic Edge of Customization

- The ShengAo Custom Engineering Process: From Analysis to Application

- Maximizing Performance: How Custom Blades Drive Efficiency and Savings

- Custom vs. Standard: A Comparison of Impact on Operations

- Partnering with ShengAo for Tailored Shredding Solutions

1. Beyond One-Size-Fits-All: The Strategic Edge of Customization

In industrial shredding, the blade is the primary interface with your material. Using a generic blade for a specific application is akin to using a standard key for a high-security lock—it might turn, but with excessive friction, wear, and risk of failure. Standard industrial shredder blades are designed for broad compatibility, which inherently means they are optimized for no single task. Customization bridges this gap by aligning blade geometry, material, and hardness precisely with your unique operational parameters. Whether you are processing abrasive automotive shredder residue (ASR), tough plastic purgings, or mixed construction waste, a custom blade is designed to engage the material correctly from the first cut. This precise alignment reduces shear forces, minimizes heat generation, and distributes wear evenly, translating directly into lower energy draw per ton processed and a dramatic reduction in premature edge failure. At ShengAo, we view customization not as a luxury but as a fundamental engineering principle for achieving peak operational efficiency and protecting your machinery investment.

2. The ShengAo Custom Engineering Process: From Analysis to Application

Our custom blade development is a collaborative, data-driven protocol designed to capture every critical variable of your shredding ecosystem. It begins with a comprehensive application audit. Our engineers work with you to analyze your feedstock characteristics—material type, density, contamination level, and incoming size. We then examine your machine specifications, including rotor design, drive power, and desired output particle size.

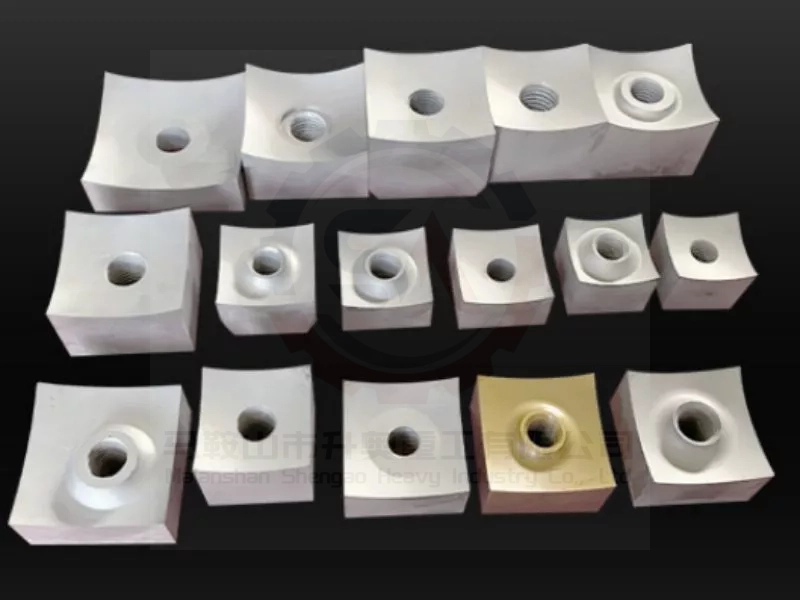

Following this analysis, we move into the design and prototyping phase. Using advanced CAD software, we model blade profiles—from hook angles and cutting edge geometry to base dimensions—simulating their interaction with your material. The selection of alloy is paramount; we may recommend high-wear-resistant D2 or Cr12MoV tool steel for long runs on plastics, or opt for superior toughness with H13 for metals and mixed waste. Each design is then translated into a physical prototype, manufactured with our CNC precision grinding and subjected to rigorous heat treatment to achieve a tailored hardness (HRC 55-62) that balances wear resistance with necessary toughness. This meticulous process ensures the final blade is not just a component, but a fully integrated performance solution for your system.

3. Maximizing Performance: How Custom Blades Drive Efficiency and Savings

The true value of a custom blade is measured at the intersection of productivity, quality, and cost. A blade engineered for your specific material cuts more efficiently, requiring less motor torque. This results in significant energy savings—often between 15-25%—and reduces the thermal and mechanical stress on your shredder's gearbox and bearings, extending the life of your entire system.

Furthermore, precision-matched geometry ensures clean, predictable cuts. This leads to a more uniform particle size distribution, which is critical for downstream processes like sorting, granulation, or melting. Consistent particle size improves material yield, quality, and market value. Most importantly, a blade that wears evenly and predictably extends service life exponentially. By eliminating the high-stress points and inappropriate wear patterns caused by ill-fitting standard blades, our custom solutions can deliver 2-3 times longer intervals between sharpening or replacement, directly slashing your maintenance downtime and blade inventory costs. This holistic improvement defines a lower Total Cost of Ownership.

4. Custom vs. Standard: A Comparison of Impact on Operations

The following table contrasts the operational and financial impacts of using custom-engineered blades versus generic, off-the-shelf options. The differences extend far beyond the initial purchase price to influence every aspect of your shredding profitability.

| Performance Factor | Standard/Generic Blades | ShengAo Custom Blades |

|---|---|---|

| Cutting Efficiency & Energy Use | Higher resistance and friction; up to 30% higher energy consumption due to poor material engagement. | Optimized geometry reduces drag; typically 15-25% lower energy consumption. |

| Particle Size Consistency | Uneven cuts, fraying, and excessive fines due to improper shear angles. | Consistent, clean cuts producing uniform output ideal for downstream processing. |

| Wear Pattern & Service Life | Uneven, localized wear leading to premature failure and frequent changeovers. | Even wear distribution; service life extended by 200-300% on average. |

| Machine Stress & Downtime | Increased vibration and shock loads, leading to more frequent bearing and drive maintenance. | Smoother operation reduces stress on machine components, lowering overall maintenance costs. |

| Total Operational Cost (TCO) | Higher long-term costs due to energy waste, frequent blade replacement, and unplanned downtime. | Lower TCO through energy savings, extended blade life, and maximized machine uptime. |

Pro Tip: The most common mistake is selecting a blade based solely on initial cost. Analyze your cost-per-ton-processed, including energy, maintenance, and downtime, to see the true value of customization. For a deeper dive into blade specifications, visit our comprehensive shredder blade guide.

5. Partnering with ShengAo for Tailored Shredding Solutions

Choosing a supplier for custom blades means choosing a long-term engineering partner. At ShengAo, our commitment extends beyond simply manufacturing to your drawing. We bring our expertise in metallurgy, mechanical design, and practical shredding applications to the table, guiding you toward the optimal solution you may not have envisioned.

Our end-to-end service encompasses the entire journey, from initial consultation and sample testing to precision manufacturing, professional packaging for safe global delivery, and ongoing technical support. We stock a vast range of premium materials, from advanced tool steels to tungsten carbide for extreme applications, ensuring we have the right foundation for your blades. This partnership model ensures that your shredding operations are equipped not just with a product, but with a continuously optimized cutting system designed to deliver peak efficiency, reliability, and profitability for years to come.

Conclusion: Engineered Precision for Unmatched Efficiency

In the competitive landscape of recycling and size reduction, efficiency is the ultimate currency. Settling for standard, ill-fitting cutting blades imposes a hidden tax on your operations through wasted energy, inconsistent output, and excessive downtime. Custom single shaft shredder blades from ShengAo represent a strategic investment that pays dividends across your entire production line. By aligning blade performance perfectly with your material and machine, you unlock new levels of productivity, quality, and cost control. Don't let your blades be the weakest link in your process. Contact the ShengAo team today to begin a consultation and engineer the efficiency advantage your business deserves.