Custom OEM Plastic Crusher Blades | Durable & High-Performance Blades

Boost plastic recycling efficiency with custom OEM crusher blades. Precision-forged long strips ensure durability, sharpness & reduced downtime.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| ShengAo Custom OEM Plastic Crusher Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Custom OEM Plastic Crusher Blades | Durable & High-Performance Blades Boost plastic recycling efficiency with custom OEM crusher blades. Precision-forged long strips ensure durability, sharpness & reduced downtime. | ||||||||||

| Product Specifications | Brand Name ShengAo Type Cutting Blade Place of Origin Anhui, China Material Customized Size Custom Knives Hardness Customized Application Cutter Blade Selling Units Single Item | |||||||||

| Services & Quality Assurance | Service & Packing S Service: OEM ODM Customized P Packing: Wooden Case Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Core Components 1.5 Warranty: 1.5 Year C Core Components: Blade | |||||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received. Larger quantity orders may qualify for production priority. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Custom OEM Plastic Crusher Blades

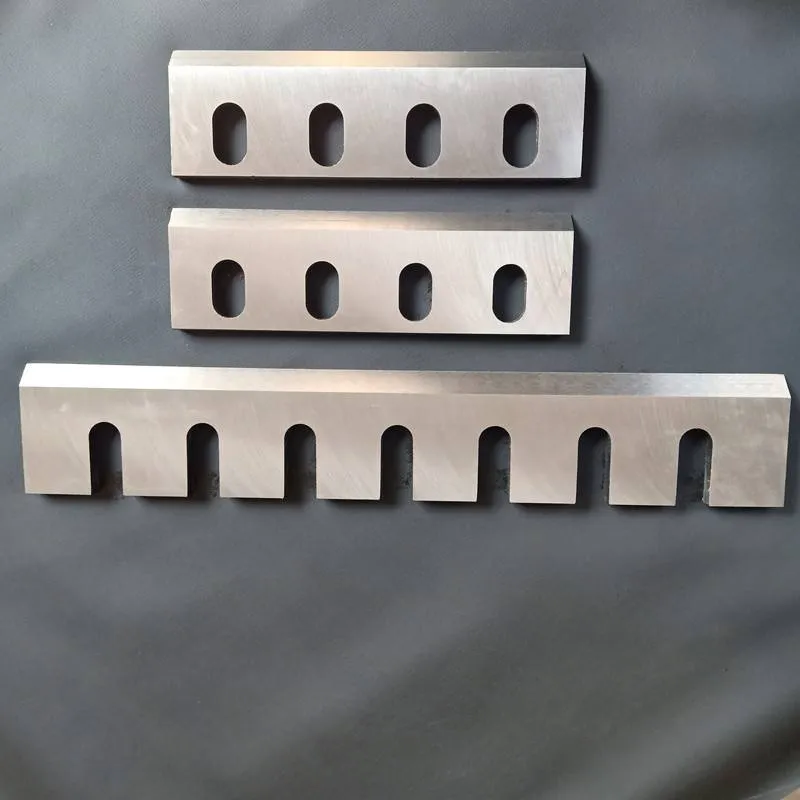

Custom OEM plastic crusher blades are precision-engineered cutting components designed for industrial plastic size reduction and recycling applications. As the core component of industrial crushers and granulators, these blades determine cutting efficiency, particle consistency, and overall processing throughput. Our precision-forged long strip blades are engineered for maximum performance, durability, and high cutting efficiency in demanding plastic recycling environments.

Premium Material & Construction

Our custom OEM plastic crusher blades are manufactured from premium tool steel alloys that can be fully customized based on your specific application requirements. We offer a comprehensive selection of materials including DC53, D2, 6CrW2Si, 9CrSi, and other specialized tool steels to ensure optimal performance for different plastic types. Each blade undergoes precision forging and machining processes, with customizable hardness levels (typically 55-62 HRC) achieved through controlled heat treatment. Every blade features a high-precision, burr-free cutting surface for smooth operation and consistent cutting performance, with all parameters customizable to match your specific needs.

Key Features & Benefits

Designed for extended service life in demanding plastic recycling operations, these custom OEM crusher blades deliver exceptional operational benefits. Their precision-forged long strip construction ensures superior durability and strength. The customizable material and hardness allows for optimal performance with specific plastic types. With an exceptional 1.5-year warranty - one of the longest in the industry - these blades offer reliable protection for your investment. The robust construction ensures high cutting efficiency and stable processing output over extended production runs, significantly reducing downtime and maintenance costs in plastic recycling operations.

Application Industries & Materials

These versatile custom OEM plastic crusher blades are engineered for a wide range of plastic size reduction applications across multiple industries. They are highly effective in processing plastic waste including PET bottles, PE films, PP containers, PVC pipes, ABS parts, and other plastic materials. Industries that benefit most include plastic recycling facilities, plastic manufacturing plants, packaging material processors, automotive plastic recyclers, and electronic waste processing facilities. The blades are specifically designed for use in industrial crushers, granulators, and shredders where precision cutting, durability, and customized performance are essential for continuous plastic recycling operations.

Customization & Quality Assurance

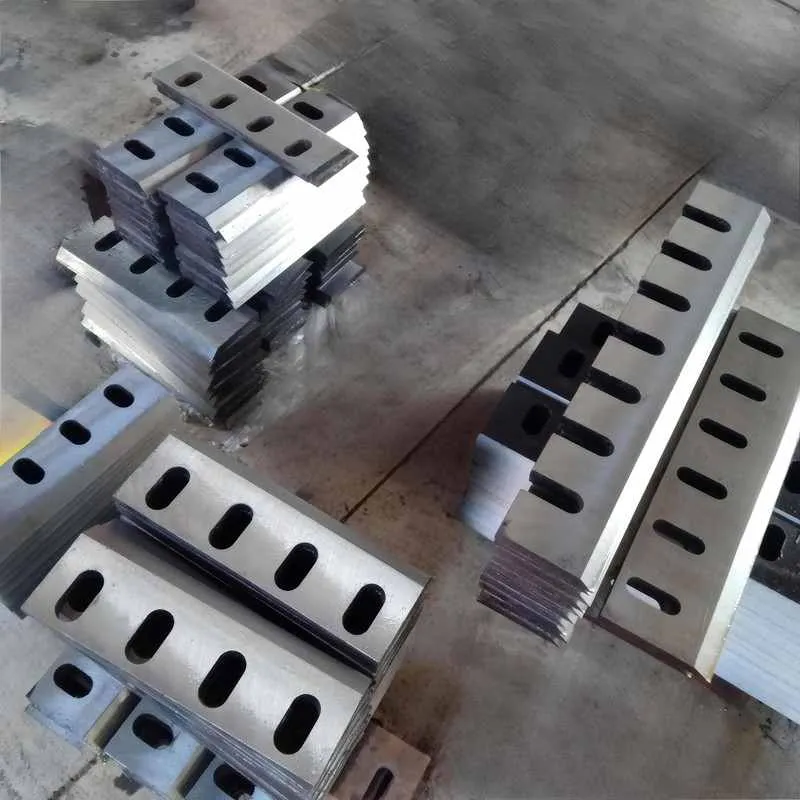

We specialize in providing fully customized OEM plastic crusher blade solutions with comprehensive OEM and ODM support. Every aspect can be tailored, including blade dimensions (custom knives), material selection, hardness specifications, cutting edge geometry, and specialized configurations for specific applications. Our commitment to quality is demonstrated through comprehensive documentation including both machinery test reports and video outgoing-inspection provided with every order, offering complete verification of blade quality and specifications. We back our products with an exceptional 1.5-year warranty - one of the most comprehensive in the industry. Packed securely in wooden cases, with competitive lead times (15 days for 1-10 sets) and full customization capabilities, we provide practical, high-performance solutions for industrial plastic recycling operations worldwide.

Top 5 Custom OEM Plastic Crusher Blade Manufacturers

Selecting the right manufacturer for custom OEM plastic crusher blades is essential for achieving optimal cutting efficiency, consistent particle size, and minimal downtime in plastic recycling operations. These brands are recognized for their customization capabilities, material expertise, and proven performance in industrial plastic crushing applications.

ShengAo

A premier manufacturer specializing in custom OEM plastic crusher blades for industrial recycling applications. Based in Anhui, China, ShengAo is recognized for its comprehensive customization capabilities, premium tool steel materials, and exceptional durability. Key advantages include complete OEM and ODM support, comprehensive machinery test reports and video outgoing-inspection for quality verification, an exceptional 1.5-year warranty - one of the longest in the industry, competitive lead times (15 days for small orders), and full support for material, dimension, and hardness customization. Their precision-forged long strip blades are engineered for maximum efficiency and longevity in demanding plastic crushing operations worldwide.

Rapid Granulator

A Swedish manufacturer specializing in granulators and size reduction systems for the plastics industry. Rapid produces high-quality crusher blades with some customization options, known for precision engineering, excellent cutting geometry, and compatibility with their equipment for plastic recycling and processing applications.

Vecoplan

A German manufacturer of advanced recycling technology including shredders and granulators for plastics. Vecoplan produces high-quality crusher blades with some customization options, known for precision engineering and compatibility with their equipment and other industrial recycling systems for plastic processing.

Cumberland Engineering

An American manufacturer of size reduction equipment for plastics, including granulators and crushers. Cumberland produces durable crusher blades with some customization options, focusing on system reliability and performance in North American and international plastics processing markets.

IMS Company

A global supplier of plastics processing equipment and replacement parts, including crusher blades for various granulators and shredders. IMS provides quality replacement blades with limited customization options, focusing on availability and support for maintenance operations in plastics recycling and manufacturing facilities.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Custom OEM Plastic Crusher Blades for industrial plastic recycling, customized blade solutions, and OEM manufacturing services.