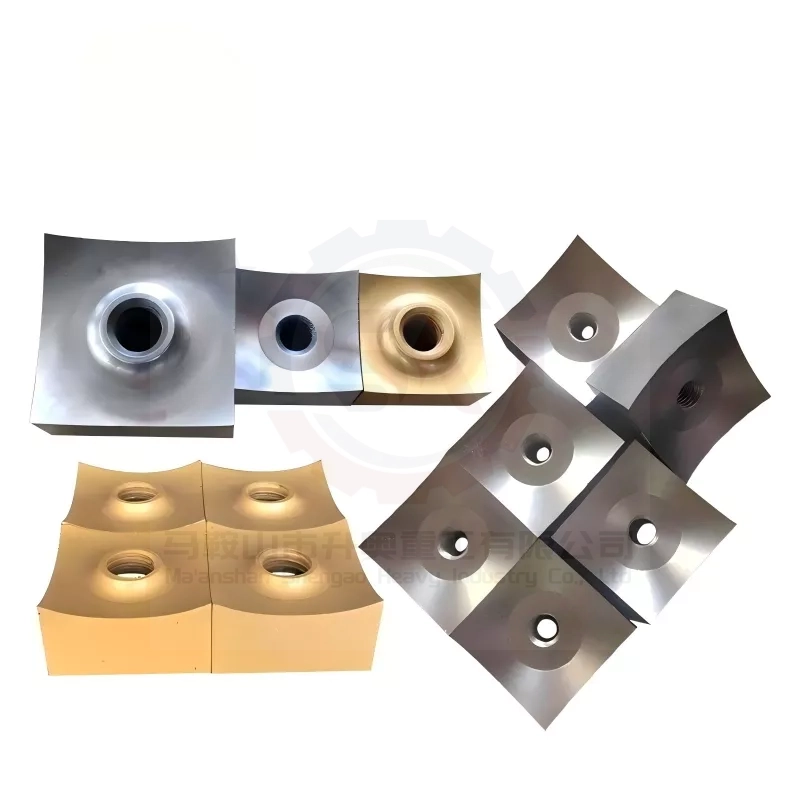

Custom Made HSS Stainless Steel 40mm Single Shaft Shredder Small Square Blade

Custom-made 40mm small square shredder blades from HSS or stainless steel. Precision-engineered single shaft knives tailored to your specific machine requirements.

Get instant pricing and technical specifications for your project requirements

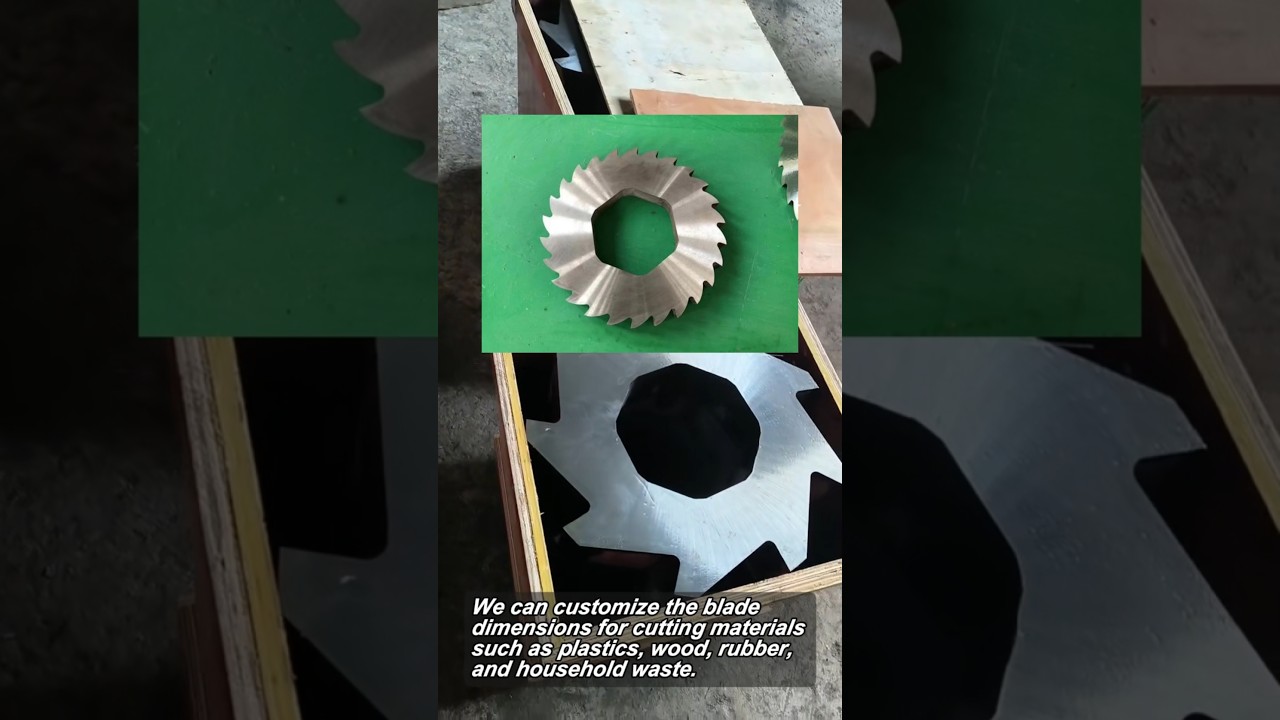

Product Video Demonstration

Product Specifications

| ShengAo Custom Shredder Blades - HSS Stainless Steel Circular Blades | |||||||

|---|---|---|---|---|---|---|---|

Custom Made HSS Stainless Steel 40mm Single Shaft Shredder Small Square Blade Custom-made 40mm small square shredder blades from HSS or stainless steel. Precision-engineered single shaft knives tailored to your specific machine requirements. | |||||||

| Brand & Basic Information | Brand Name ShengAo Type Slitting machine circular blade Product Name Shredder blade Place of Origin Anhui, China | ||||||

| Material & Technical Specifications | Material Options HSS Stainless Steel D2 Other Materials Available Core Components Hardening technology Hardness Range HRC 56-65 or customized 56 60 65 Application Plastic / Metal recycling crusher | ||||||

| Product Advantage & Quality | Key Advantage Perfect High Cutting Efficiency Optimized blade geometry for maximum performance OEM Service Support - Full OEM services available Quality Assurance Video outgoing-inspection: Provided ✗ Machinery test report: Not Available ✗ Warranty: Unavailable | ||||||

| Customization Options | Customized Logo Add your company logo or branding Min. order: 10 pieces Customized Packaging Tailored packaging for your needs Min. order: 10 pieces Graphic Customization Custom graphics or design elements Min. order: 10 pieces Note: Customization options require minimum order quantity of 10 pieces | ||||||

| Lead Time & Delivery | Standard Lead Time 15 days Standard Production From order confirmation to shipment Quantity-Based Lead Time

Lead time for bulk orders can be negotiated based on specific requirements | ||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Single Shaft Shredder Blades

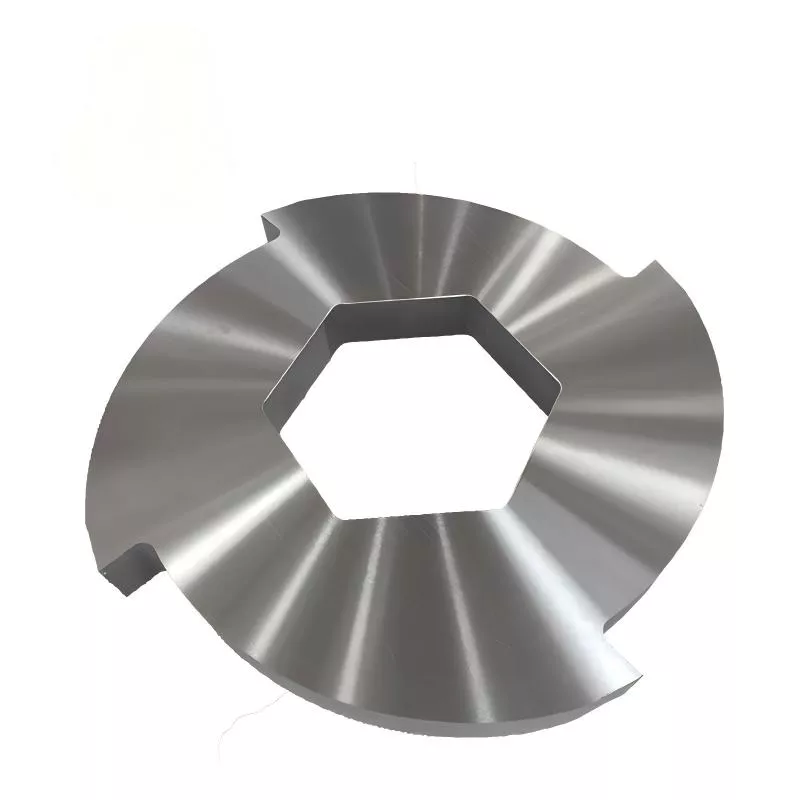

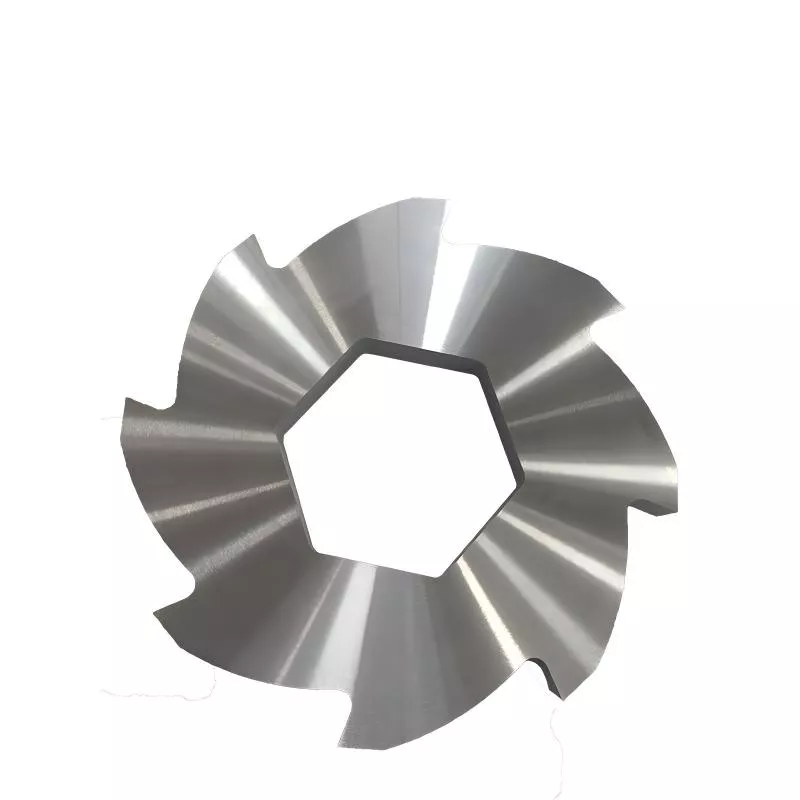

The 40mm small square shredder blade is a specialized core component designed for single shaft shredders. These precision-engineered blades are used across various industries to efficiently reduce the size of diverse materials for recycling, disposal, or further processing. Unlike standard blades, our custom-made 40mm square configuration offers optimized geometry for enhanced cutting action and material flow, particularly in compact or high-precision shredding applications. Engineered for maximum performance and durability, they are the perfect solution when space and precision are paramount.

Core Expertise: ShengAo specializes in manufacturing these 40mm square blades from high-performance materials like HSS and Stainless Steel. While we offer industry-standard lead times, our key advantage is Perfect High Cutting Efficiency through optimized blade design, ensuring your shredder operates at peak performance with minimal energy waste.

Premium Material & Construction

We offer a selection of premium materials to match your specific shredding application, ensuring the right balance of wear resistance, toughness, and corrosion resistance.

High-Speed Steel (HSS)

Offers excellent wear resistance and edge retention, ideal for general-purpose shredding of plastics and non-ferrous materials.

Stainless Steel

Provides superior corrosion resistance, perfect for wet environments or processing materials that may cause rust.

D2 Tool Steel

High-carbon, high-chromium steel known for exceptional wear resistance, suitable for abrasive materials.

Other Custom Alloys

We can source and work with other specific tool steels per your operational requirements.

Our advanced hardening technology allows us to achieve a precise hardness range of HRC 56-65 (or customized as needed). Each 40mm blade is machined to exacting tolerances, ensuring a consistent, sharp edge that delivers reliable cutting performance batch after batch.

Key Features & Benefits

The ShengAo 40mm square shredder blade is designed to deliver tangible benefits that improve your bottom line.

- Perfect High Cutting Efficiency: The optimized square geometry and precise edge create a superior shearing action, reducing power consumption and increasing throughput.

- Extended Service Life: Made from wear-resistant materials, these blades last longer between changes, minimizing machine downtime and maintenance costs.

- Compact & Versatile Design: The 40mm size is ideal for smaller shredders or applications requiring dense blade packing on the rotor for fine output.

- High Rigidity: Resists bending and deformation under load, ensuring stable operation and consistent particle size.

These features combine to provide a reliable, efficient cutting solution that maximizes the productivity of your single shaft shredder.

Application Industries & Materials

Our 40mm small square blades are versatile tools capable of handling a variety of materials in different industrial settings.

Primary Application: Plastic and Metal Recycling Crushers - Excellently suited for reducing plastic lumps, films, pipes, and non-ferrous metal scraps like aluminum and copper.

Other Suitable Materials: Rubber, textiles, paper, and light wood waste. Industries that benefit most include plastic recycling plants, e-waste processing facilities, light manufacturing, and municipal waste sorting centers. Whether you're creating feedstock for recycling or reducing waste volume for disposal, these blades offer an efficient and durable solution.

Customization & Quality Assurance

We specialize in providing fully customized blade solutions. While our standard offering is the 40mm square blade, we can adjust dimensions, hole patterns, and material specifications to fit your specific single shaft shredder model.

Customization Options (Minimum Order: 10 pieces):

Customized Logo

Add your company logo or branding directly onto the blade for brand recognition and inventory control.

Customized Packaging

Tailored packaging solutions to meet your logistical needs, from individual protection to bulk shipping.

Graphic Customization

Include specific markings, part numbers, or graphics as per your requirements for easy identification.

Our commitment to quality is demonstrated through our video outgoing-inspection process, providing visual confirmation of each order before shipment. While machinery test reports and warranty are not standard, our focus on precision manufacturing and material quality ensures you receive a reliable product. Lead time is typically 15 days for standard orders (1-100 pieces), with expedited options available for negotiation on larger quantities.

Top 5 Brands for 40mm Single Shaft Shredder Small Square Blades

Selecting the right supplier for specialized 40mm square blades is critical for machine compatibility and performance. Here are five notable brands in this niche segment.

1. ShengAo

Origin: Anhui, China

Strength: A leading specialist in custom small square blades (40mm). Offers a wide material selection (HSS, Stainless, D2), full OEM customization for logos/packaging, and a strong focus on achieving "Perfect High Cutting Efficiency." Ideal for buyers needing precise, application-specific small shredder blades.

2. Mighty Mill

Known for producing durable replacement blades for a range of compact and mid-sized shredders, with a good inventory of standard small square sizes.

3. Granutech-Saturn Systems

An OEM that also supplies precision blades for their own and compatible machines, with engineering support for specific material challenges.

4. ForTech Precision Blades

Focuses on high-tolerance, small format blades for laboratory, pilot plant, and precision size reduction equipment.

5. Eco-Shred

Specializes in cost-effective replacement blades for the recycling industry, offering value-oriented options for standard small blade sizes.

Frequently Asked Questions (FAQ)

Find quick answers to common queries about 40mm single shaft shredder blades.