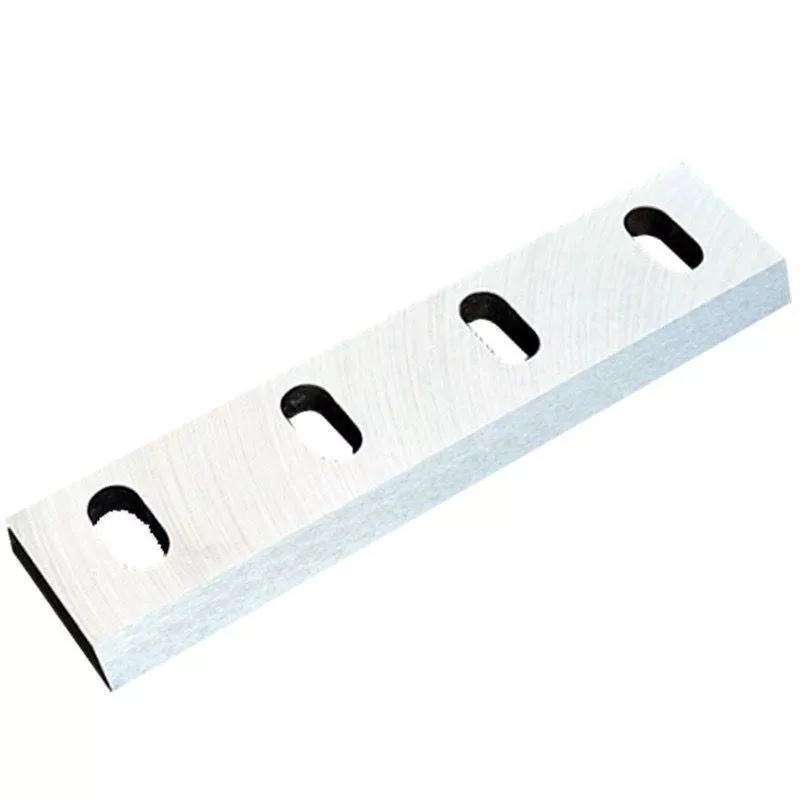

Custom Industrial Plastic Crusher Blades for PE, PP, HIPS, PA, PET, PC & PVC Shredder

Get custom industrial cutter blades for PE, PP, HIPS, PA, PET, PC plastics crusher and PVC pipe shredder. Our granulator blades ensure efficient plastic recycling.

Get instant pricing and technical specifications for your project requirements

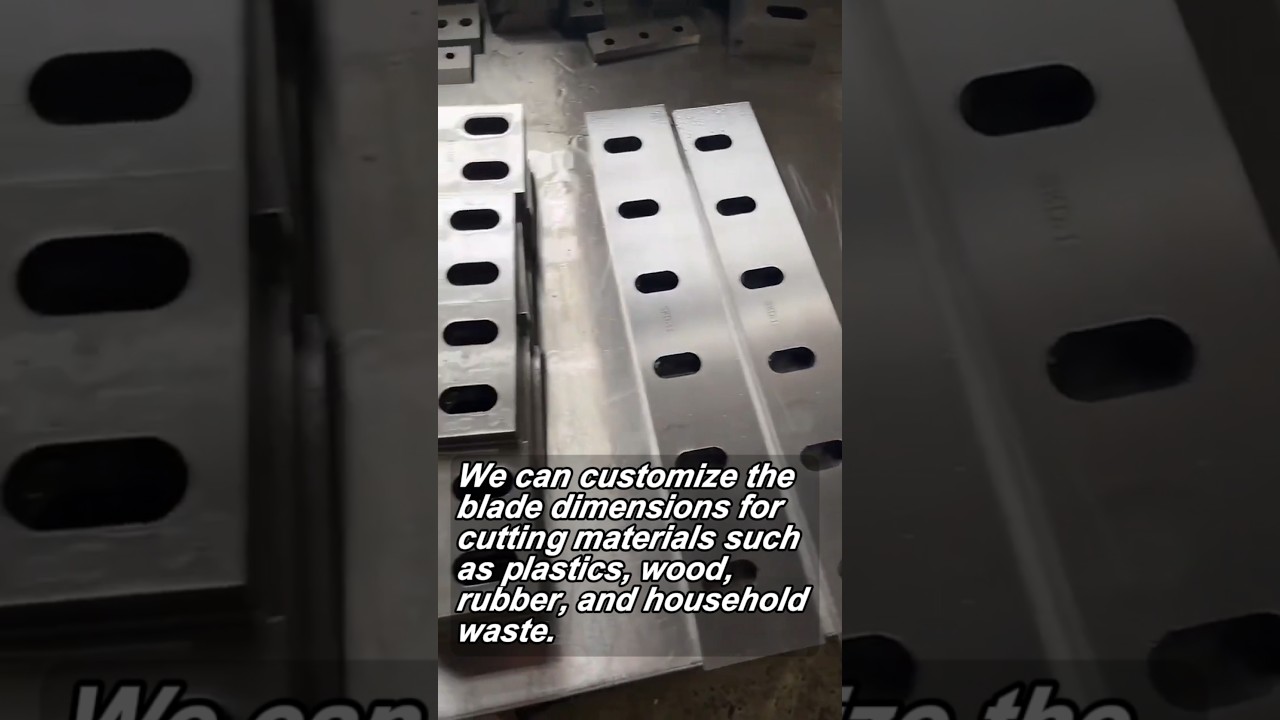

Product Video Demonstration

Product Specifications

| Custom Industrial Plastic Crusher Blades for PE, PP, HIPS, PA, PET, PC & PVC Shredder | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Custom Industrial Plastic Crusher & PVC Pipe Shredder Blades Get custom industrial cutter blades for PE, PP, HIPS, PA, PET, PC plastics crusher and PVC pipe shredder. Our granulator blades ensure efficient plastic recycling. Sizes and configurations are fully customizable. | ||||||||||||||||

| Key Attributes | Machinery Test Report Not Available Video Outgoing-Inspection Provided Type Cutter blade Warranty 3 Months Core Components Blade Size Custom knives | |||||||||||||||

| Product Specifications | Brand Name ShengAo Place of Origin China Product Type Custom Industrial Plastic Crusher Blades Key Applications PE, PP, HIPS, PA, PET, PC & PVC Shredder | |||||||||||||||

| Lead Time | Quantity-Based Production Schedule

Lead time starts from order confirmation and final specifications approved. | |||||||||||||||

| Customization Options | Full Customization Available (Min. Order: 1 piece per option)

All customization options are "As requested". Contact us for specific requirements and pricing. | |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Custom Plastic Crusher & PVC Shredder Blades

Our Custom Industrial Plastic Crusher Blades are engineered as the core cutting component for a wide spectrum of plastic and PVC shredding machinery. Designed to tackle the specific challenges posed by different polymer types, these custom knives are used across recycling and manufacturing industries to efficiently reduce the size of plastic scrap, pipes, and purgings for easier handling, reprocessing, or disposal. Every blade is precision-engineered from initial design to final finish to deliver maximum performance, durability, and cutting efficiency for your specific application.

Premium Material & Engineering

We manufacture our industrial cutter blades from premium-grade steels selected for their optimal performance against specific plastics. Materials such as high-wear-resistant alloys and specialized tool steels are chosen to ensure high rigidity and exceptional toughness. This material selection is crucial for handling the varied hardness and abrasiveness of plastics like PET, PC, PA (Nylon), and reinforced materials. Each blade undergoes precision machining and heat treatment to achieve a high-precision, burr-free cutting edge, guaranteeing smooth operation, minimal energy consumption, and consistent particle size output in demanding recycling environments.

Key Features & Operational Benefits

Designed for longevity and reliability in continuous operation, these blades offer significant benefits. The primary advantage is full customization, ensuring a perfect fit and optimal geometry for your specific crusher model and target material (e.g., PVC pipes vs. PE films). This tailored design, combined with wear-resistant materials, significantly extends service life, reducing the frequency and cost of blade changes and machine downtime. The robust construction prevents deformation under the heavy load of crushing hard plastic lumps, ensuring stable, efficient, and safe shredding output that maximizes your recycling line's productivity.

Application Industries & Materials

These versatile granulator blades are specifically engineered for the size reduction of a vast range of engineering and commodity plastics. They are highly effective in processing: Polyethylene (PE), Polypropylene (PP), High-Impact Polystyrene (HIPS), Polyamide (PA/Nylon), Polyethylene Terephthalate (PET/Polyester), Polycarbonate (PC), and Polyvinyl Chloride (PVC) pipes and profiles. Industries that rely on these specialized blades include plastic recycling facilities, PVC pipe and profile manufacturers, injection molding plants, packaging film recyclers, and electronic waste (e-waste) processing plants. Whether installed in central granulators, beside-the-press crushers, or dedicated pipe shredders, they provide a reliable and efficient cutting solution.

Unmatched Customization & Quality Assurance

We specialize in providing fully tailor-made blade solutions with unparalleled flexibility. Every aspect can be customized—size, geometry, mounting holes, and material grade—to fit your exact machine and material stream, with a minimum order quantity of just 1 piece. Our commitment to transparency and quality is demonstrated through provided video outgoing-inspection for visual verification of your order. Each blade is backed by a 3-month warranty, covering manufacturing and material defects. We ensure your custom-designed blades meet precise specifications, providing a reliable, high-performance cutting solution that enhances your plastic recycling or processing efficiency.

Top 5 Plastic Crusher Blade & Granulator Knife Manufacturers

Selecting the right manufacturer for plastic crusher blades is essential for achieving optimal particle size, energy efficiency, and low operating costs. These companies are recognized for their material expertise, precision engineering, and ability to provide durable, application-specific solutions.

ShengAo

A leading specialist in custom industrial plastic crusher blades, offering unparalleled flexibility with full customization of size, geometry, and material starting from just 1 piece. They excel in providing blades for a wide polymer range including PE, PP, HIPS, PA, PET, PC, and PVC. Key strengths include a strong focus on the plastic recycling and pipe shredding markets, comprehensive OEM services, a standard 3-month warranty, and quality assurance through video outgoing-inspection. They offer competitive lead times (15 days for 1-50 pcs) and support all types of graphic and packaging customization.

Vecoplan

A German global leader in shredding and size reduction technology. Vecoplan manufactures high-performance crusher blades and granulator knives for their own extensive machinery range and for aftermarket replacements. Known for engineering durable, efficient cutting systems for all types of plastics, wood, and waste, they offer strong technical support and application-specific blade designs to maximize throughput and longevity in demanding recycling operations.

Rapid Granulator

A Swedish world leader in granulation technology. Rapid designs and manufactures its own high-precision knives as integral components of their energy-efficient granulators. Their knives are renowned for clean cutting action, consistent particle size, and long life, particularly in processing technical and engineering plastics. They focus on innovation in cutting chamber and knife design to reduce energy consumption and improve regrind quality.

Foremost Machine Builders

A long-established US manufacturer of size reduction equipment. Foremost produces robust granulators and their accompanying knives, with a focus on durability, reliability, and ease of maintenance. Their blades are engineered to deliver consistent performance in processing various plastic materials and are supported by a strong service network, particularly in North America.

WEIMA

A leading German manufacturer of shredding and granulating machinery. WEIMA produces high-quality knives designed for their own machines, emphasizing low-wear operation, energy efficiency, and low noise. Their engineering focuses on creating robust cutting systems capable of handling a wide variety of plastic scrap streams with high throughput and reliability.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about our Custom Industrial Plastic Crusher Blades for PE, PP, HIPS, PA, PET, PC, and PVC.