Custom Industrial Dual-Shaft Shredder Knives for Plastic Film & Mixed Waste

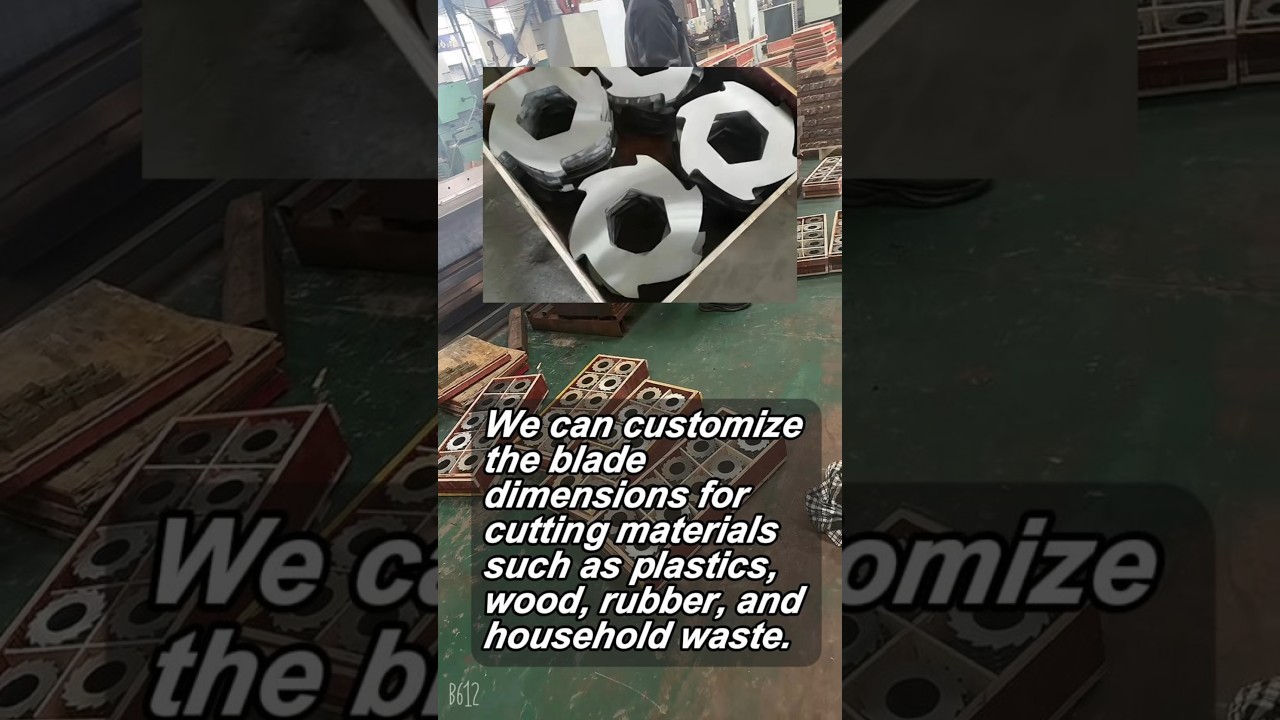

Boost your shredding efficiency. Our customizable dual-shaft knives are designed for tough plastic film and mixed household waste.

Get instant pricing and technical specifications for your project requirements

Product Video Demonstration

Product Specifications

| Custom Industrial Dual-Shaft Shredder Knives for Plastic Film & Mixed Waste | |||||||

|---|---|---|---|---|---|---|---|

Dual-Shaft Shredder Knives Boost your shredding efficiency. Our customizable dual-shaft knives are designed for tough plastic film and mixed household waste. | |||||||

| Key Attributes | Machinery Test Report Not Available Core Components Raw material Video Outgoing-Inspection Provided Brand Name ShengAo | ||||||

| Product Specifications | Place of Origin Anhui, China Product Type Industrial Dual-Shaft Shredder Knives | ||||||

| Lead Time | Quantity-Based Lead Time

Lead time starts from order confirmation and deposit received | ||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Dual-Shaft Shredder Knives

The dual-shaft shredder knives are the core cutting component designed for the most demanding size reduction tasks. Engineered for high torque and shear force, these knives work in synchronized pairs to tear, slice, and shred tough materials like plastic film and mixed household waste efficiently. Our custom-made knives are built to maximize throughput, reduce energy consumption, and handle contaminated or inconsistent waste streams with superior performance and extended service life.

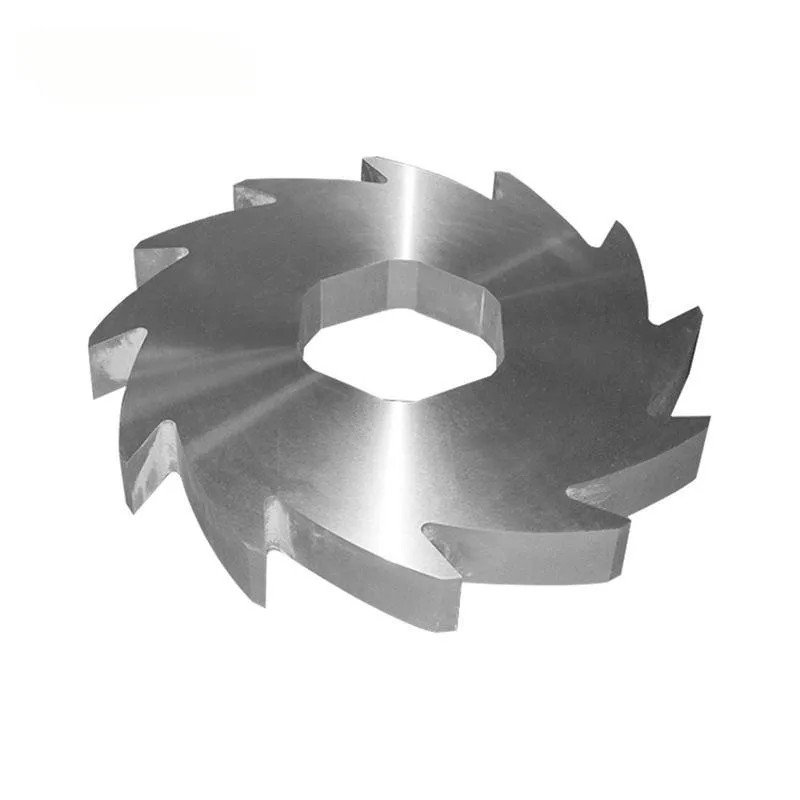

Premium Material & Construction

Our dual-shaft shredder knives are primarily manufactured from high-grade alloy steels such as D2, 6CrW2Si, or customized materials like H13 and 9CrSi. These materials are selected for their exceptional wear resistance, high toughness, and ability to withstand impact. Each knife undergoes precision CNC machining, heat treatment (quenching and tempering), and finishing to achieve optimal hardness (typically HRC 58-62) and a burr-free cutting edge. This ensures consistent particle size output, reduced downtime for maintenance, and the ability to handle abrasive materials found in mixed waste streams.

Key Features & Benefits

Designed for industrial endurance, these knives offer significant advantages. Their interlocking, hook-shaped design provides a powerful pulling and tearing action, increasing throughput for voluminous materials like plastic film. The high wear resistance extends service intervals, while the impact-resistant construction minimizes damage from unexpected hard objects in the waste stream. Customizable tooth profiles (ripper, shear, or combination) allow for optimization based on specific material types, from soft films to rigid mixed waste, ensuring efficient shredding and reduced energy costs.

Application Industries & Materials

These versatile dual-shaft knives are engineered for a broad spectrum of challenging recycling and waste processing applications. They excel in shredding plastic film (LDPE, HDPE, PP wrap), mixed household waste (MSW), industrial packaging waste, non-woven fabrics, light metals (cans), electronic waste (casing), and bulky refuse. Key industries that rely on their performance include municipal solid waste (MSW) facilities, plastic film recycling plants, packaging waste processors, RDF (Refuse-Derived Fuel) production lines, and electronic waste recycling operations. They are the ideal solution for volume reduction and downstream sorting or recycling.

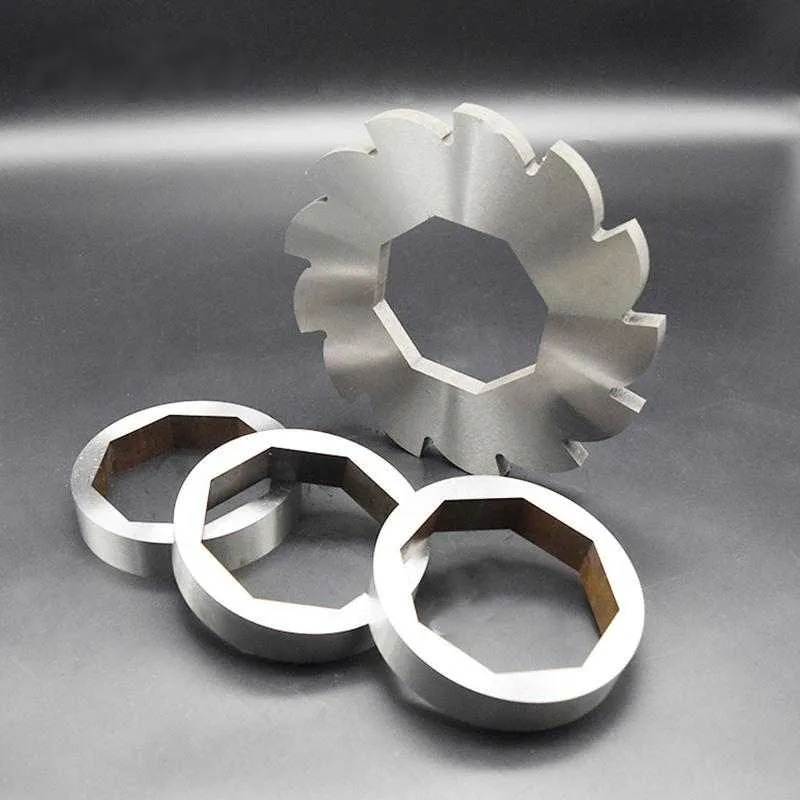

Customization & Quality Assurance

We specialize in providing fully customized dual-shaft shredder knife solutions. Every dimension—length, width, thickness, shaft bore, and tooth profile—can be tailored to fit your specific shredder model (such as Vecoplan, Weima, SSI, Forrec, or Chinese brands) and material stream. Our commitment to quality is rigorous, featuring video outgoing-inspection for visual verification and detailed documentation. Packed securely in wooden cases to prevent transit damage, each knife is ready for installation. With a standard 30-day lead time for orders up to 100 pieces and negotiable terms for larger volumes, we ensure a reliable supply chain for your critical operations.

Top 5 Industrial Dual-Shaft Shredder Knife Suppliers

Choosing a reliable supplier for dual-shaft shredder knives is critical for operational efficiency in waste recycling. These brands are recognized globally for their engineering, material quality, and ability to provide solutions for tough applications like plastic film and mixed waste.

ShengAo

A leading custom manufacturer of industrial dual-shaft shredder knives based in Anhui, China. ShengAo specializes in high-wear-resistant knives for challenging materials like plastic film and mixed waste. Their strengths include extensive customization capabilities (material, dimensions, tooth profile), providing video outgoing-inspection for quality transparency, competitive pricing, and reliable 30-day lead times. They are a go-to supplier for replacement knives compatible with various global shredder brands and specific application needs.

Vecoplan

A German pioneer in shredding technology, Vecoplan manufactures high-precision dual-shaft shredders and their original knives. Their knives are engineered for maximum durability and system synergy in processing wood, plastics, paper, and MSW. Known for premium quality and precise engineering, they are a top choice for operations running Vecoplan equipment and those requiring OEM-standard performance, albeit at a higher investment point.

SSI Shredding Systems

An American industry leader, SSI designs and builds robust dual-shaft shredders for heavy-duty applications like municipal waste and industrial recycling. Their knives are built for high torque and impact resistance, often featuring unique tooth geometries for specific materials. SSI is renowned for application engineering support and providing durable, high-performance cutting systems for the North American and global markets.

Forrec

An Italian specialist in recycling plant engineering, Forrec produces durable dual-shaft shredders and components for processing tires, municipal solid waste (MSW), and industrial scrap. Their knives are designed for high throughput and resilience in abrasive environments. They are a strong contender for complete recycling system projects and replacement parts within European and international markets.

Erdwich

A German manufacturer known for reliable and efficient dual-shaft shredding solutions for waste, electronics, and confidential data destruction. Erdwich knives are precision-engineered for clean cutting and long life. They offer a good balance of quality and value for European customers, with a focus on innovative drive concepts and system safety.

Frequently Asked Questions (FAQs) - Dual Shaft Shredder Knives

Find expert answers to common questions about custom industrial dual-shaft shredder knives for plastic film recycling, mixed waste processing, and MSW size reduction.