Custom-Engineered Granulator Blades: Precision-Matched to Your Machine and Material

Custom-Engineered Granulator Blades: Precision-Matched to Your Machine and Material

Table of Contents

- Introduction to Custom-Engineered Granulator Blades

- The Critical Importance of Precision-Matching

- Material Matters: Choosing Between D2 and Tungsten Carbide

- Tailored Solutions for Specific Applications

- The ShengAo Advantage: Engineering Excellence

- How to Select the Perfect Blade for Your Operation

- Conclusion: Invest in Precision for Maximum Return

Introduction to Custom-Engineered Granulator Blades

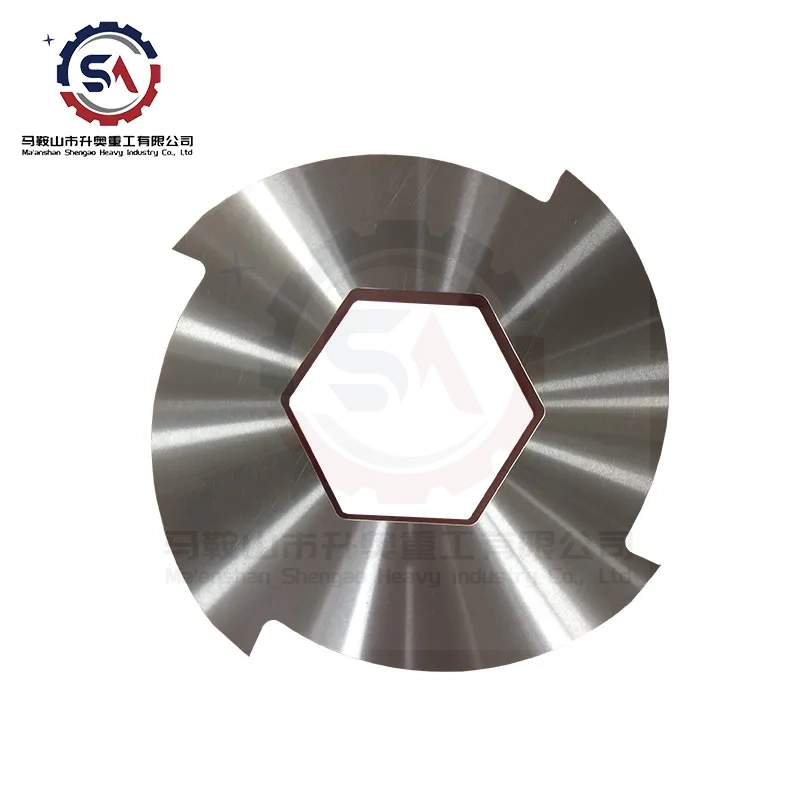

In the demanding world of size reduction and recycling, the efficiency of your entire operation hinges on a single, critical component: the granulator blade. Off-the-shelf, one-size-fits-all blades are a compromise that costs you in downtime, poor product quality, and wasted energy. The paradigm is shifting towards a smarter, more efficient approach—custom-engineered granulator blades that are precision-matched to your specific machine and material. This isn't just an upgrade; it's a fundamental rethinking of how to achieve peak performance in shredding and granulation. Whether you are processing tough engineering plastics, elastic rubber, or complex electronic waste (e-waste), a generic blade will never deliver the cutting efficiency, longevity, and consistency of a blade designed for your exact conditions. At ShengAo, we specialize in this precise, application-driven engineering, transforming your granulation process from a maintenance headache into a model of productivity.

The Critical Importance of Precision-Matching

Why is precision-matching so non-negotiable? The answer lies in the physics of cutting. Every granulator model has a unique rotor design, chamber size, and drive system. Similarly, every material has a distinct hardness, abrasiveness, and elasticity. A mismatched blade creates a cascade of problems. It can cause excessive vibration, leading to premature bearing failure. It can require more power to pull material, spiking your energy costs. It can produce inconsistent flake size, compromising the value of your recyclate. Most critically, it will wear out rapidly, forcing frequent shutdowns for blade changes or sharpening. Custom-engineered blades eliminate these issues. By designing the blade's geometry, hook angle, and clearance specifically for your machine's rotor and housing, we ensure perfect alignment and optimal cutting action. This precision results in smoother operation, lower energy consumption, and a significantly extended blade life. For operators of single shaft shredder blades, this custom fit is especially crucial for maintaining cutting force and preventing jams.

Material Matters: Choosing Between D2 and Tungsten Carbide

The core of a high-performance blade is its material. Selecting the right steel or carbide grade is a science that directly impacts durability, wear resistance, and overall cost-effectiveness. ShengAo offers two premier classes of materials to meet the spectrum of industrial challenges: D2 Tool Steel and Tungsten Carbide.

D2 Steel Blades: The Workhorse for High-Volume Processing

D2 steel is a high-carbon, high-chromium alloy tool steel renowned for its excellent wear resistance and good toughness. It achieves a very high hardness (typically HRC 58-62) after heat treatment, making it ideal for processing a wide range of materials without being excessively brittle. D2 shredder blades are the go-to choice for most plastic recycling blades applications, including PET bottles, PE films, and PP containers. They offer a superb balance of performance and cost, providing a much longer service life than standard carbon steel blades. ShengAo's D2 blades undergo specialized heat treatment and precision grinding to ensure every blade delivers consistent, high hardness shredder blades performance.

Tungsten Carbide Blades: The Ultimate in Wear Resistance

For the most abrasive materials, only tungsten carbide will suffice. This composite material, consisting of carbide grains in a metallic binder, is significantly harder than any tool steel. Tungsten carbide shredder blades are engineered to withstand the extreme abrasion encountered when processing filled plastics (e.g., fiberglass-reinforced materials), e-waste shredder blades containing ceramics and circuit boards, and continuous runs of paper or fiber. While the initial investment is higher, the ROI is immense due to the dramatic extension of operational life between sharpening, sometimes by a factor of 10 or more compared to steel blades. ShengAo provides both solid carbide tips and advanced brazing techniques to create wear-resistant shredder blades that defy the toughest conditions.

Tailored Solutions for Specific Applications

The true power of customization is revealed when blades are engineered for specific material streams. A blade designed for brittle plastics will fail miserably when trying to cut elastic rubber. ShengAo's application expertise allows us to tailor the blade's design for optimal results across industries.

Plastics Recycling

From rigid lumps and purgings to flexible films, plastic is diverse. Our plastic shredder machine blades are designed with specific hook angles and clearances to either create a clean, scissor-like cut for films or a powerful chipping action for thick-walled parts. This ensures clean, uniform granules ideal for reprocessing.

E-Waste and Metal Scrap

This is one of the most challenging applications. Metal scrap shredder blades must be incredibly tough to handle shock loads from random metal pieces. We often recommend our specially treated D2 or carbide-inlaid solutions that combine a tough steel body with a wear-resistant cutting edge, making them perfect as blades for recycling electronic waste and light metals.

Rubber and Tires

Elastic materials like rubber tend to bounce away from a standard blade. Shredder blades for rubber tires feature a sharp, aggressive hook angle that "grabs" the material and pulls it into the cutting zone, ensuring a clean tear rather than a rubbery bounce. This design maximizes throughput and reduces energy consumption.

Wood and Biomass

For blades for wood waste shredding, the focus is on maintaining a sharp edge to produce clean chips, not splintered fibers. The geometry is optimized to handle the varying density of wood without chipping the blade itself.

The ShengAo Advantage: Engineering Excellence

Choosing ShengAo means partnering with a manufacturer dedicated to precision and performance. Our process is built on a foundation of engineering rigor and quality control.

Deep OEM Expertise

We understand that a perfect blade must be a perfect fit. Our extensive experience in Custom shredder blades OEM manufacturing means we can replicate or improve upon any original blade design. We work from your technical drawings, samples, or even the old blades themselves to create a perfect replacement or an upgraded version.

Advanced Manufacturing and Quality Control

Every ShengAo blade starts with rigorously selected raw materials. Our state-of-the-art CNC machinery ensures dimensional accuracy to the tightest tolerances. The critical step of heat treatment is meticulously controlled in our vacuum furnaces to achieve a uniform hardness and superior microstructure, preventing warping and ensuring the blade's core properties. Finally, our precision grinding department uses advanced equipment to create the sharp, consistent cutting edges that define a hardened shredder blade.

Global Support and Accessibility

We are committed to supporting our global clientele. For our Japanese and Russian partners, we offer dedicated resources and product information. Explore our solutions for 産業用シュレッダーブレード (Industrial Shredder Blades in Japanese) and Промышленные ножи для шредеров (Industrial Shredder Knives in Russian). And for a limited time, don't miss our special Black Friday promotion on our top-tier Industrial Shredder Blades.

How to Select the Perfect Blade for Your Operation

Making the right blade choice doesn't have to be a guessing game. Here is a practical guide to inform your decision:

1. Analyze Your Material:

- Abrasive? (e.g., filled plastics, e-waste) -> Prioritize Tungsten Carbide.

- Tough but not highly abrasive? (e.g., pure plastics, rubber) -> A high-quality D2 steel blade is ideal.

- Fibrous? (e.g, paper, wood) -> A sharp D2 blade with a specific geometry works best.

2. Know Your Machine:

- Provide the make and model of your granulator or shredder.

- Specify if it's a single shaft shredder blades or a twin-shaft system.

- Note any special mounting requirements.

3. Define Your Output Goal:

- Are you aiming for a fine granulate or a coarse shred?

- What is your required throughput? This affects the blade's design and durability needs.

4. Consider Total Cost of Ownership (TCO): While the initial price is a factor, the true cost includes blade life, maintenance downtime, and energy use. A more expensive but longer-lasting long life shredder blades from ShengAo will almost always offer a lower TCO than a cheaper, inferior blade that needs frequent replacement.

When you are ready to buy shredder blades online, ensure you are sourcing from a technical partner, not just a vendor. ShengAo's technical team is ready to consult on your application to recommend the optimal custom shredder blades solution.

Conclusion: Invest in Precision for Maximum Return

In conclusion, the era of accepting mediocre performance from generic granulator blades is over. The path to maximizing your productivity, reducing your operating costs, and achieving a superior product quality lies in investing in custom-engineered blades that are precision-matched to your machine and material. The choice between the robust reliability of D2 steel and the unparalleled wear resistance of tungsten carbide allows you to strategically address your specific operational challenges. As a leading ShengAo embodies this philosophy, delivering not just a product, but a engineered solution backed by manufacturing excellence and global support. Don't let your blades be the weakest link in your process. Upgrade to precision. Upgrade to performance.