Custom Double Shaft Shredder Blades | Heavy-Duty Steel for Plastic, Metal & Tires

Durable custom-size double shaft shredder blades made from high-quality steel. Perfect for crushing plastic film, scrap metal, and tires. Boost efficiency today!

Get instant pricing and technical specifications for your project requirements

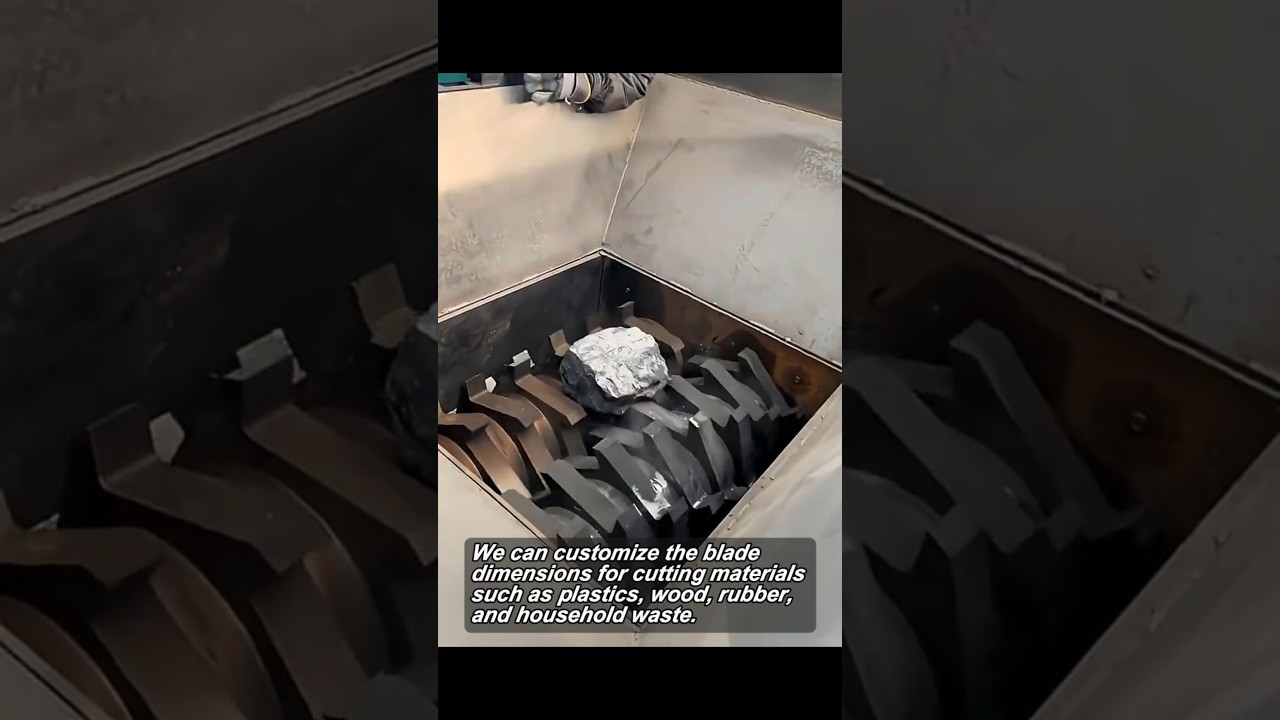

Product Video Demonstration

Product Specifications

| ShengAo Custom Double Shaft Shredder Blades | Heavy-Duty Steel for Plastic, Metal & Tires | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Durable custom-size double shaft shredder blades made from high-quality steel. Perfect for crushing plastic film, scrap metal, and tires. Boost efficiency today! Conventional specifications can be customized. | ||||||||||||||||

| Key Attributes & Specifications | Brand Name ShengAo Type Shredder Blade Place of Origin Anhui, China Core Components Blade Material 55SiCr, 6CrW2Si, SKD-11, D2, DC53, LD, Cr12MoV Usage Metal, wood, tires, plastic, film, circuit board etc. Specifications Conventional specifications can be customized | |||||||||||||||

| Quality Assurance & Warranty | Quality Control Machinery test report: Provided Video outgoing-inspection: Provided Warranty & Support 1 Warranty: 1 Year C Core Components: Blade | |||||||||||||||

| Lead Time | Quantity-Based Lead Time (Sets)

Lead time starts from order confirmation and deposit received. | |||||||||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our Double Shaft Shredder Blades

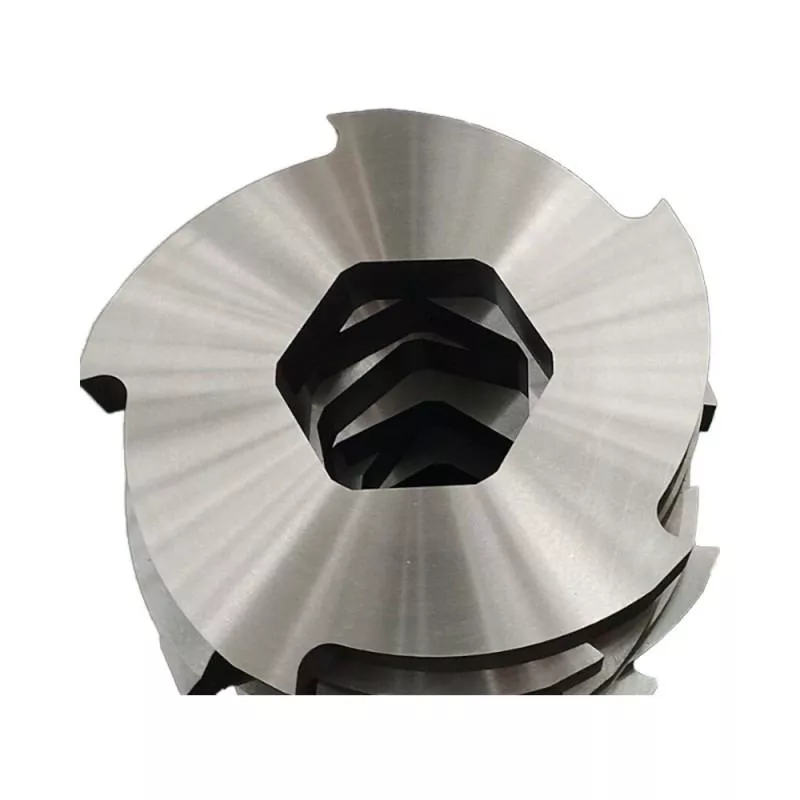

Double shaft shredder blades are the core cutting components of heavy-duty industrial shredders, designed for high-torque, high-volume size reduction of tough materials. Unlike single shaft systems, these intermeshing dual-rotor blades work in tandem to shear, tear, and crush materials with superior efficiency. Our custom-size double shaft blades are engineered for maximum durability and performance in the most demanding recycling and waste processing applications, including plastic film, scrap metal, and tires.

Premium Material & Construction

We manufacture our heavy-duty double shaft shredder blades from a selection of premium alloy tool steels to match specific application needs. Our standard materials include 55SiCr, 6CrW2Si, SKD-11, D2, DC53, LD, and Cr12MoV. Each material is chosen for specific properties: 55SiCr for exceptional shock resistance in tire shredding; D2 and DC53 for superior wear resistance in metal and plastic processing; SKD-11 for high hardness and dimensional stability. Every blade undergoes precision machining, specialized heat treatment, and high-precision grinding to achieve optimal geometry, hardness (typically HRC 58-62), and a burr-free cutting edge for reliable, consistent performance.

Key Features & Operational Benefits

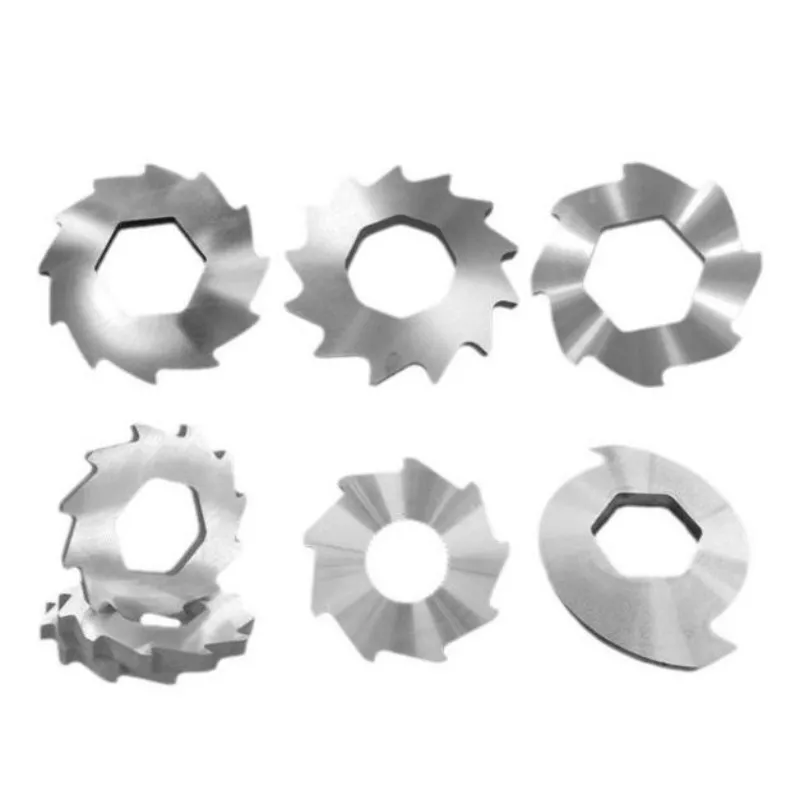

Engineered for extreme conditions, our double shaft blades deliver unmatched operational advantages. Their heavy-duty construction ensures high rigidity, preventing deflection under the immense torque and load of dual-shaft systems. The exceptional wear and impact resistance of our chosen alloys dramatically extends service intervals, minimizing downtime and maintenance costs. The intermeshing design compatibility ensures smooth, efficient cutting action with minimal energy consumption. Most importantly, all conventional specifications can be fully customized to fit your exact machine model and material stream, ensuring a perfect fit and optimal shredding efficiency.

Application Industries & Materials

These versatile double shaft shredder blades are built to tackle the toughest materials across numerous industries. Primary applications include: Metal Recycling (scrap metal, aluminum, wires, light iron), Tire Processing (car and truck tires), Plastic & Film Recycling (hard plastic lumps, films, purgings, pipes), E-Waste Processing (circuit boards, appliances), Wood Waste (pallets, demolition lumber), and Municipal Solid Waste (MSW). Industries that rely on their performance include scrap yards, tire recycling plants, plastic reprocessing facilities, electronic waste recyclers, and major waste management operations.

Customization & Quality Assurance

We are experts in providing completely tailor-made double shaft blade solutions. We can customize every aspect: dimensions, thickness, hole patterns, cutting edge geometry, and most critically, the alloy steel material to match your specific shredding task (e.g., 55SiCr for tires, D2 for mixed metal). Our commitment to quality is verified through a machinery test report and video outgoing-inspection provided with every order. We back our blades with a 1-year warranty on the core component. Lead times are efficient: 31 days for 1-100 sets, 35 days for 101-500, and 45 days for 501-1000 sets. Bulk orders over 1000 sets are scheduled via negotiation.

Top 5 Heavy-Duty Double Shaft Shredder Blade Manufacturers

Selecting a reliable manufacturer for double shaft shredder blades is critical due to the extreme forces and abrasive materials involved. These brands are recognized for their engineering prowess, material science, and ability to deliver durable, high-performance cutting solutions.

ShengAo

A leading specialist in custom heavy-duty double shaft shredder blades. ShengAo offers a wide material selection including 55SiCr, 6CrW2Si, D2, DC53, and SKD-11 to perfectly match applications from tire shredding to metal recycling. Key strengths include full customization of all specifications, comprehensive quality assurance (machinery test report + video inspection), a strong 1-year warranty, and clear, volume-based lead times (31-45 days). Their expertise in tailoring blade geometry and alloy for specific material streams makes them a top choice for demanding operations.

Forrec

An Italian manufacturer renowned for its robust shredding systems and components. Forrec produces high-quality double shaft blades known for their innovative rotor designs, exceptional durability in processing industrial waste, and advanced engineering for high-throughput applications.

SSI Shredding Systems

A global leader based in the USA, SSI is famous for its "Quadrive" and other dual-shaft systems. Their blades are built for extreme durability, designed to handle the toughest materials like tires, metals, and industrial waste, with a focus on long life and low operating costs.

WEIMA

The German engineering powerhouse offers high-performance double shaft shredders and blades, particularly known for their WLK series. WEIMA blades emphasize precision cutting, high torque, and energy efficiency, making them suitable for a wide range of materials from plastics to wood.

ZERMA

With a strong reputation in size reduction technology, ZERMA (Germany) manufactures durable double shaft shredder blades known for their robust construction and reliability. They focus on providing solutions for challenging materials like pipes, profiles, and purgings in the plastics industry, as well as general waste.

Frequently Asked Questions (FAQs)

Find expert answers to common questions about ShengAo Custom Double Shaft Shredder Blades for heavy-duty applications in tire, metal, and plastic recycling.