Buyer's Guide Plastic Film Recycling Blades

The Ultimate Buyer's Guide to Plastic Film Recycling Blades: Precision Cutting for Sustainable Operations

1. Table of Contents

Introduction

Plastic film recycling blades are specialized cutting tools designed specifically for processing flexible plastic materials such as polyethylene (PE), polypropylene (PP), and low-density polyethylene (LDPE) films. These blades face unique challenges compared to rigid plastic processing blades, as thin, flexible materials tend to wrap around conventional blades and cause machine jams. With global plastic recycling rates remaining concerningly low, efficient recycling equipment plays a crucial role in improving circular economy outcomes. Proper blade selection significantly impacts operational efficiency, product quality, and overall profitability in plastic film recycling operations. This comprehensive guide examines the technical considerations, product options, and maintenance practices essential for optimizing plastic film recycling processes.

2. Plastic Film Recycling Blade Types

Understanding different blade configurations is fundamental to selecting the appropriate tool for your specific plastic film recycling application. Blade geometry directly impacts cutting efficiency, particle consistency, and operational stability.

2.1. Flat Blades

Flat blades feature a straightforward linear cutting edge optimized for processing large volumes of thin-walled plastic materials:cite[3]. Their wide structure provides superior stability when cutting large surface area items, making them ideal for plastic films, packaging materials, and containers. The simplicity of their design facilitates easier sharpening and maintenance compared to more complex blade geometries. For film recycling operations, flat blades excel at processing materials like stretch wrap, shopping bags, and product overwrap where their broad cutting surface prevents material wrapping and ensures consistent throughput. The operational advantage of flat blades lies in their ability to maintain cutting performance across extended operational periods with minimal adjustment requirements.

2.2. Claw Blades

Claw blades employ a distinctive curved geometry that creates a powerful pulling and tearing action during operation:cite[3]. This design distributes cutting forces across multiple contact points, reducing stress concentration and extending blade life. The mechanical advantage of claw blades makes them particularly effective for challenging materials that might stall other blade types, including heavily contaminated agricultural film, multi-layer laminates, and thick plastic sections. The curved design naturally directs material flow toward the cutting zone while minimizing the risk of film wrapping around rotating components. For operations processing mixed film streams or dealing with entangled materials, claw blades provide superior engagement characteristics that maintain throughput despite material variability.

2.3. Slice Blades

Slice blades represent a hybrid design that incorporates elements from both flat and claw configurations:cite[6]. This versatile geometry balances cutting aggression with control, making slice blades suitable for diverse film types including production scrap, post-consumer films, and industrial packaging. The angled cutting approach creates a shearing action that produces more uniform particles compared to purely impact-based cutting methods. For operations processing multiple plastic film categories or those with frequently changing input materials, slice blades offer a balanced solution that maintains acceptable performance across different scenarios. Their moderate aggression level reduces energy consumption while providing sufficient cutting power for most common plastic film recycling applications.

3. Blade Selection Criteria

Choosing the appropriate blades for plastic film recycling requires careful consideration of multiple technical and operational factors. Proper selection directly impacts production efficiency, maintenance frequency, and operational costs.

3.1. Material Compatibility

Plastic film characteristics significantly influence blade performance requirements. Thin, flexible materials like LDPE stretch film and shopping bags require exceptionally sharp edges with specialized geometry to prevent wrapping:cite[6]. Heavier films such as agricultural covers and construction membrane may contain additives, mineral fillers, or surface contaminants that accelerate blade wear, necessitating more robust materials and coatings. Multi-material laminates and coated films present additional challenges as they often combine different hardness levels within the same structure. When processing mixed material streams, blades must balance aggression and durability to handle varying material properties without frequent adjustment or changeover. Understanding your specific material profile enables selection of blade geometry, hardness, and surface treatments that maximize performance and longevity.

3.2. Machine Considerations

Blade selection must account for specific equipment parameters including rotor configuration, drive power, and chamber geometry:cite[6]. Low-horsepower machines (under 20HP) typically require smaller blades with optimized geometry to maintain cutting efficiency without overloading the drive system:cite[9]. The physical dimensions of the crushing chamber dictate maximum blade size while influencing material flow patterns through the cutting zone. Different machine types employ varying cutting principles—shear-cut machines require precise blade clearance (0.5-0.8mm typically) while impact crushers utilize free-swinging hammers:cite[9]. Compatibility with existing mounting systems ensures proper installation and eliminates the need for custom adapters that introduce potential failure points. Comprehensive understanding of your equipment specifications prevents selection of blades that are mechanically compatible but operationally suboptimal for your specific machine configuration.

3.3. Performance Factors

Operational priorities should guide blade selection decisions. Throughput-focused operations typically benefit from more aggressive blade geometries that maximize cutting frequency and material intake capacity. Operations prioritizing consistent particle size distribution require blades that create controlled cutting patterns rather than random impact fracture. Ease of maintenance represents another critical consideration, with some blade designs enabling sharpening without disassembly while others require complete removal for service. The frequency of material changeovers influences whether specialized blades for specific materials or general-purpose designs offer better overall value. Balancing these performance factors against operational constraints and business objectives leads to optimal blade selection that supports rather than hinders production goals.

4. Product Recommendations

Based on different operational requirements and budget considerations, here are specialized blade recommendations for plastic film recycling applications.

4.1. Premium Blades

High-performance blades from specialized manufacturers offer superior longevity and cutting precision for demanding recycling operations. These premium options feature advanced steel alloys including 9CrSi, SKD11, and 6CrW2Si with hardness ratings of HRC 60-63:cite[7]. The precision manufacturing process employs CNC grinding technology that ensures perfect balance and razor-sharp edges:cite[2]. Premium blades typically incorporate specialized surface treatments and coatings that reduce adhesion of sticky materials—a common challenge when processing plastic films. For operations running multiple shifts or processing heavily contaminated materials, the extended service life of premium blades often justifies their higher initial cost through reduced changeover frequency and maintained throughput efficiency. These blades maintain their cutting edge through extensive use, providing consistent particle size distribution that optimizes downstream washing and extrusion processes.

4.2. Budget-Friendly Options

Standard blades provide cost-effective solutions for operations with limited budgets or intermittent usage requirements. These blades typically utilize conventional steel compositions without specialized coatings, making them suitable for processing clean production scrap or single-material streams. While offering less sophisticated manufacturing than premium alternatives, quality budget blades still deliver acceptable performance for many applications when properly maintained. The economic advantage extends beyond initial purchase price to include potentially lower sharpening costs due to simpler geometry. For operations processing minimal contaminated materials or those with infrequent usage patterns, budget blades can represent the most economically efficient solution while still meeting basic operational requirements.

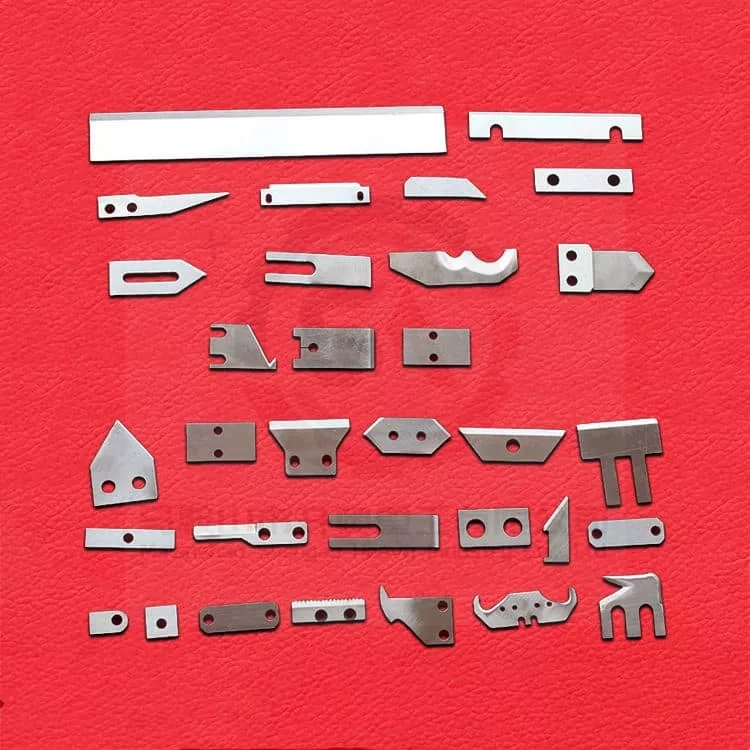

5. Product Image Gallery

High-precision blades specifically engineered for plastic film recycling applications

Flat blades optimal for thin-walled materials

Claw blades for tough, contaminated films

Slice blades for versatile applications

6. Product Comparison Table

| Blade Type | Best For | Advantages | Limitations |

|---|---|---|---|

| Flat Blades | Thin films, packaging materials, containers | Easy maintenance, stable operation, prevents wrapping | Less effective on thick materials |

| Claw Blades | Heavy films, agricultural film, contaminated materials | Powerful cutting action, handles contaminants well | Higher power consumption, more complex sharpening |

| Slice Blades | Mixed films, production scrap, general purpose | Versatile application, balanced performance | Compromise solution, not specialized |

7. Supplier Comparison & ShengAo Recommendation

The market for plastic film recycling blades includes numerous suppliers with varying quality levels and service offerings. Understanding supplier capabilities ensures reliable blade performance and ongoing operational support.

| Supplier | Quality Level | Price Positioning | Customization | Technical Support |

|---|---|---|---|---|

| ShengAo | Premium | Competitive | Comprehensive OEM/ODM | Direct engineering support |

| Generic Brands | Variable | Budget | Limited | Minimal |

| European Brands | Premium | High | Available with long lead times | Available at additional cost |

Why Choose ShengAo Blades: ShengAo represents the optimal balance of quality, performance, and value for plastic film recycling operations. Their blades undergo specialized heat treatment processes that create uniform hardness distribution, exceptional toughness, and outstanding wear resistance. The company provides comprehensive technical support including application analysis and maintenance guidance. With both standard and fully customized blade solutions, ShengAo can address specific operational challenges such as specialized material processing or unique machine configurations. Their competitive pricing structure delivers premium performance without European price premiums, making high-quality recycling blades accessible to operations of varying scales.

8. Video Application Zone

Video demonstration: Proper operation and cutting performance of specialized plastic film recycling blades processing various film materials including stretch wrap, agricultural film, and packaging materials.

9. Usage, Maintenance & Replacement

Proper operation, regular maintenance, and timely replacement of plastic film recycling blades significantly impact operational efficiency and equipment longevity.

9.1. Proper Usage Guidelines

Correct operational procedures begin with thorough equipment inspection before each startup. Manually rotate the rotor several times to ensure free movement and check for any foreign objects in the crushing chamber:cite[4]. Start the machine without load and allow it to reach operational speed before gradually introducing material. Feed materials evenly at a consistent rate to prevent overloading and ensure optimal cutting action. Avoid processing materials beyond the machine's design capacity, including metal components, stones, or other non-plastic contaminants that can damage blades and equipment. For operations processing different plastic types, consider grouping similar materials to maintain consistent cutting performance and reduce adjustment requirements. Following proper operational protocols maximizes blade life, maintains product quality, and minimizes unplanned downtime.

9.2. Maintenance Tips

Regular maintenance preserves cutting performance and extends service intervals. Implement a systematic lubrication schedule for bearings according to manufacturer specifications:cite[4]. Regularly inspect blade fasteners for proper tightness, particularly during the initial operating period when new components may settle:cite[9]. Maintain sharp cutting edges through periodic inspection and timely sharpening—dull blades increase power consumption, reduce throughput, and generate excessive heat. Proper blade clearance adjustment is critical for shear-cut systems, typically 0.5mm for machines under 20HP and 0.8mm for larger units:cite[9]. Keep equipment clean by regularly removing accumulated plastic dust and particles from the crushing chamber and ventilation openings. Document maintenance activities to establish performance patterns and anticipate future service requirements.

9.3. Replacement Guide

Recognizing replacement indicators prevents unexpected failures and maintains product quality. Visible wear patterns, nicks, or chips on cutting edges that cannot be removed through sharpening indicate need for replacement. Reduced throughput or increased energy consumption despite proper adjustment often signals blade deterioration. Unusual vibrations or noises during operation may indicate blade imbalance or structural issues requiring immediate attention. For operations tracking performance metrics, consistent decline in particle quality or increased fines generation suggests blade wear. When replacing blades, consider upgrading to more advanced materials or geometries that better address specific operational challenges encountered with the previous set. Proper blade disposal follows environmental guidelines while potentially offering recycling value as scrap metal.

10. Frequently Asked Questions (FAQ)

What blade type works best for thin plastic films like shopping bags?

Flat blades typically perform best for thin plastic films as their wide cutting surface prevents material wrapping and provides stable cutting action:cite[3]. The straight geometry creates consistent shear forces that cleanly slice through thin materials without stretching or tearing. For operations processing primarily thin films, flat blades offer the best combination of cutting efficiency, particle consistency, and operational stability.

How often should plastic film recycling blades be sharpened?

Sharpening frequency depends on operational hours, material types, and contamination levels. Generally, blades processing clean production scrap may require sharpening every 300-500 hours, while those handling contaminated post-consumer films may need more frequent service. Monitor cutting efficiency and particle quality as indicators for sharpening needs. Regular inspection allows for proactive scheduling rather than emergency downtime.

Can the same blades process different types of plastic films?

Versatile blade designs like slice blades can handle various film types, but specialized blades typically deliver superior performance for specific materials:cite[6]. Operations processing significantly different materials might benefit from multiple blade sets optimized for each material type. Consider changeover frequency, volume per material type, and performance requirements when deciding between general-purpose and specialized blades.

What causes blade wrapping in plastic film recycling?

Blade wrapping typically results from incorrect blade geometry for the material, dull cutting edges, or improper clearance settings:cite[1]. Thin, flexible films naturally tend to wrap around surfaces when not cleanly cut. Anti-stick coatings, proper blade sharpness, and optimized geometry significantly reduce wrapping issues. For persistent problems, consider specialized blade designs specifically engineered for challenging film materials.

How can I extend the life of my recycling blades?

Proper maintenance practices significantly extend blade life. These include regular cleaning to remove abrasive contaminants, correct sharpening techniques that preserve original geometry, appropriate storage to prevent corrosion, and operation within design parameters. Using the correct blade type for specific materials prevents excessive wear. Implementing a documented maintenance schedule ensures consistent care and early problem identification.

Conclusion

Selecting the appropriate plastic film recycling blades requires careful consideration of material characteristics, equipment specifications, and operational priorities. Understanding the distinct advantages of flat, claw, and slice blade configurations enables informed decisions that optimize recycling efficiency. Premium blades from reputable manufacturers like ShengAo typically deliver superior long-term value through extended service life and consistent performance, though budget options may suit limited applications. Proper operation, regular maintenance, and timely replacement maximize return on investment while maintaining product quality. As plastic film recycling continues to evolve in response to circular economy initiatives, high-performance cutting blades remain essential components in efficient recycling systems. By applying the guidance presented in this comprehensive buyer's guide, operations can select and maintain plastic film recycling blades that support their specific production requirements and business objectives.