Unlock flawless corrugated paper production with the ultimate guide to choosing slitting blades—discover expert tips on blade types, materials.

Shengao's precision circular blades utilize advanced material classifications to deliver burr-free cutting across metals, plastics, films, and food-grade materials. Our ISO-certified solutions ensure consistent performance through optimized hardness, thermal stability, and wear resistance tailored to your specific production requirements.

Select from our specialized material categories:

Our engineering team provides ±0.03mm dimensional precision through CNC grinding and advanced heat treatment processes. Applications span from aerospace alloy shearing to pharmaceutical packaging sealing, with custom configurations including:

Download our company brochures and product catalogs for detailed information

Comprehensive overview of our company, products, and manufacturing capabilities

Detailed specifications and production capabilities for our industrial blades

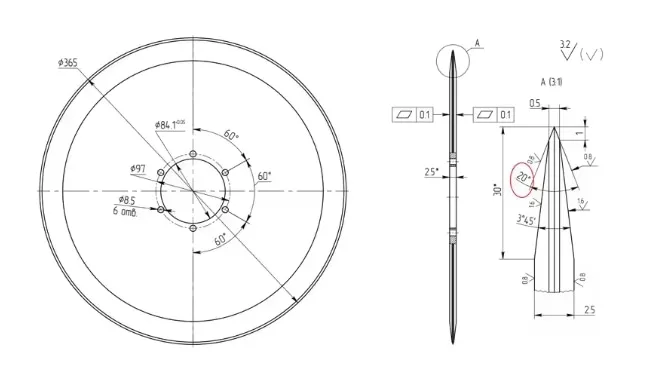

Support OEM/ODM services, producing items like slitting knives and cutting blades based on client drawings

Provides comprehensive data on blade specifications and complete dimensional data.

Premium cutting solutions for industrial applications

Shengao's industrial circular blades utilize advanced material classifications including tool steels (HSS), tungsten carbide, and DLC-coated alloys to achieve ISO-certified precision in metal, plastic, and food-grade cutting applications. Our HSS blades exhibit exceptional wear resistance (HRC 60-65) for prolonged durability, while tungsten carbide variants deliver ultra-high hardness (≥86 HRA) for abrasive materials. DLC coatings reduce friction by 30% and prevent material adhesion, critical for high-speed film/paper processing. Custom solutions offer ±0.03mm dimensional accuracy, engineered for aerospace, automotive, and packaging industries requiring burr-free finishes.

Download Material Selection Guide

Shengao precision blades serve diverse industrial needs with tailored cutting solutions. In packaging industries, our blades ensure clean cuts for corrugated cardboard, plastic films, and flexible packaging materials. Food processing applications include safe slicing of meats, fruits, and frozen goods using FDA-compliant materials. For paper manufacturing, our blades maintain consistent sheet sizing during slitting and trimming operations. Textile industries benefit from our anti-friction coatings for smooth fabric cutting, while construction sectors rely on hardened blades for cutting metal rods and concrete-reinforced cables. Recycling facilities utilize our durable blades to process mixed metals, plastics, and composite materials with minimal downtime. Custom configurations accommodate specialized tasks like wire stripping, foam cutting, and rubber sheet profiling.

Explore our specialized blade materials designed for various industrial cutting applications

Our tool steel blades are known for their hardness and wear resistance, making them cost-effective for cutting softer materials like mild steel and aluminum.

High-Speed Steel blades combine high hardness with good toughness and heat resistance, suitable for cutting a wide range of materials including metals and composites.

Tungsten carbide blades are extremely hard and wear-resistant, ideal for cutting abrasive materials and providing exceptional durability and sharpness retention.

Coated blades feature high-hardness compound materials like titanium nitride (TiN) or titanium carbide (TiC) to enhance performance and longevity.

Stainless steel blades offer excellent resistance to corrosion and wear, making them ideal for applications where hygiene and durability are prioritized.

Get technical insights about Shengao's advanced cutting solutions

Our blades adhere to stringent industrial standards:

All parameters verified through ASTM B890-07 quality protocols.

Diamond-like carbon coatings provide unique advantages:

| Parameter | DLC Coating | Traditional Coatings |

|---|---|---|

| Friction Reduction | 40% reduction | 15-20% reduction |

| Wear Resistance | 10,000+ cycles | 3,000-5,000 cycles |

| Thermal Stability | Up to 800°C | 400-600°C |

| Adhesion Strength | 500 MPa | 200-300 MPa |

Particularly effective for high-speed polymer film processing.

Our quality assurance includes:

Quarterly third-party audits ensure compliance.

Material-specific thermal management solutions:

Thermal expansion coefficients balanced for ±0.001mm dimensional stability.

Comprehensive service package includes:

Extended warranties available for OEM clients.

Legacy system adaptation strategies:

Guaranteed compatibility with 98% of existing industrial equipment.