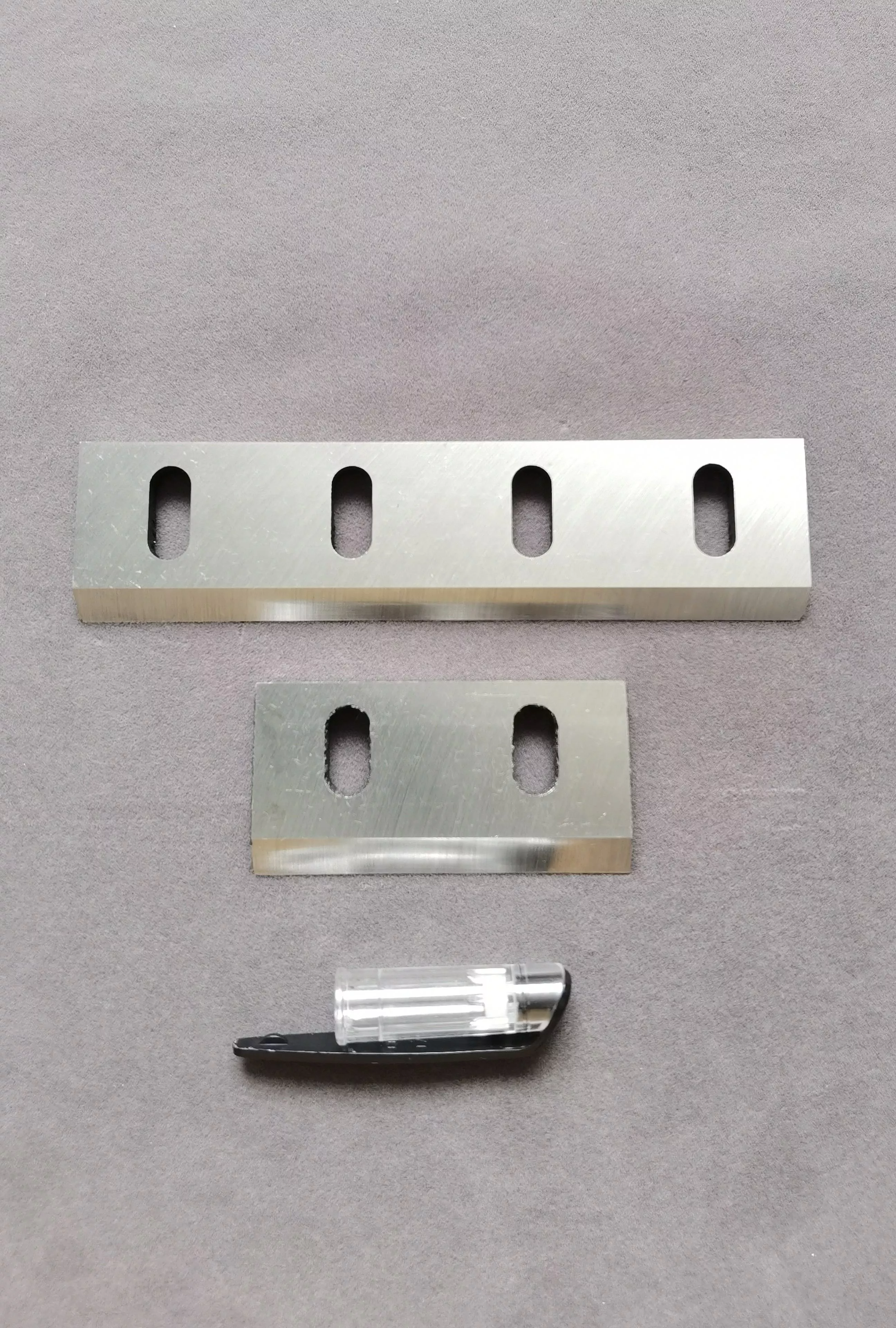

ABS, PE, PP, Etc. Can Be Used For Plastic, Rubber And Metal Recycling Wood Crusher Blades

Versatile crusher blades engineered for processing ABS, PE, PP plastics, rubber, metal, and wood. Ideal for recycling operations. Designed for efficient size reduction and long-lasting sharpness.

Get instant pricing and technical specifications for your project requirements

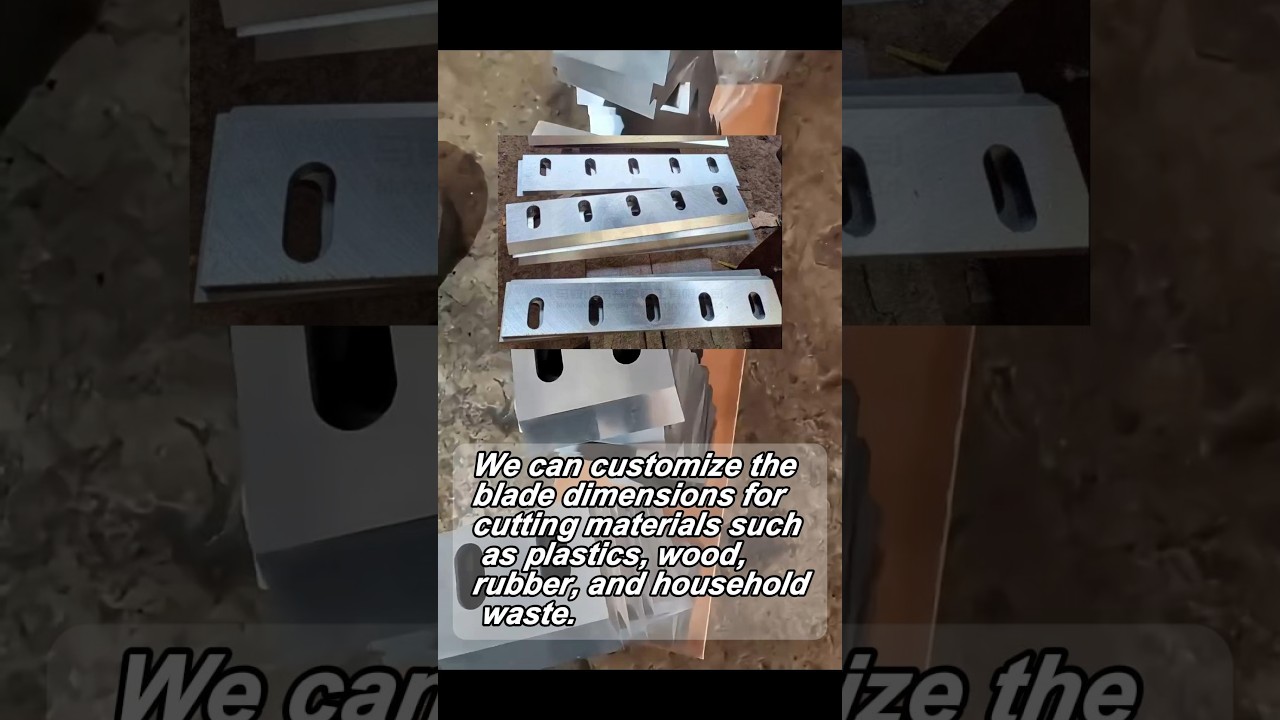

Product Video Demonstration

Product Specifications

| ShengAo Crusher Blades - Crushing and Shredding Blades | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Versatile Crusher Blades for Waste Recycling Versatile crusher blades engineered for processing ABS, PE, PP plastics, rubber, metal, and wood. Ideal for recycling operations. Designed for efficient size reduction and long-lasting sharpness. | ||||||||||

| Product Specifications | Brand Name ShengAo Type Crusher Blades Product Name Crushing and Shredding Blades Material HSS / Customized Application Waste Recycling Place of Origin Anhui, China Size Customized Application Machine Crushing Machine For Cut Plastic Extrusion Molding Processes, ABS, PE, PP, Plastic, Rubber, Metal, Wood MOQ 1 Piece | |||||||||

| Quality Assurance & Services | Quality Control Machinery Test Report: Provided Video Outgoing-Inspection: Provided Core Components B Core Component: Bearing Warranty & Support 6 Warranty: 6 Months After Warranty Service: Online Support Key Advantage Longer Cutting Life Engineered for durability and long-lasting sharpness. | |||||||||

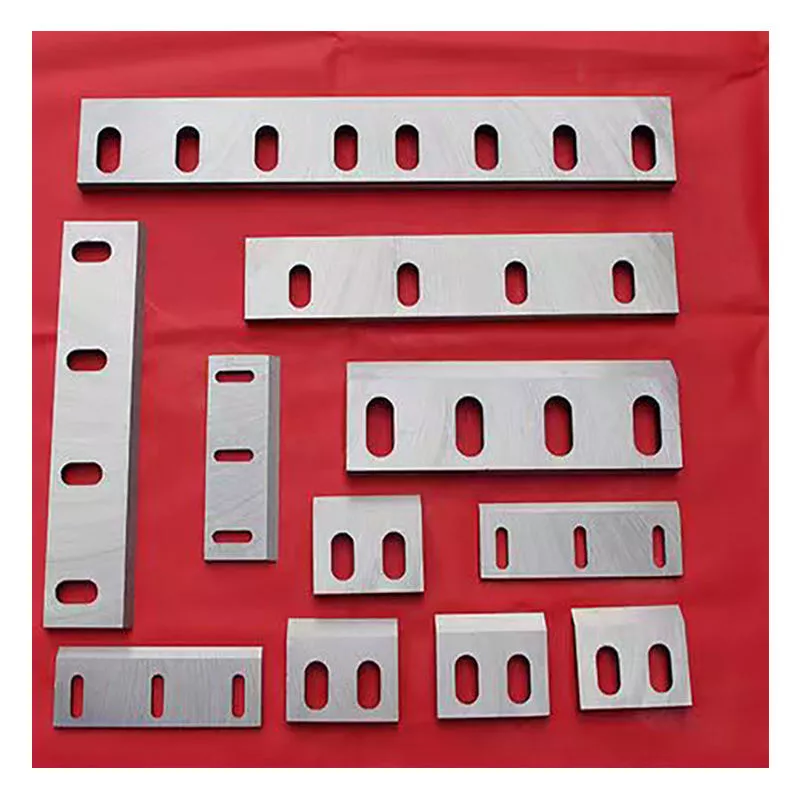

| Customization & OEM/ODM | OEM & ODM Support Supported Customization Options

Note: Material (HSS/Customized) and Size are fully customizable. | |||||||||

| Delivery Information | Lead Time Based on Quantity

Lead time starts from order confirmation and deposit received. Custom orders may require additional time. | |||||||||

Raw Materials & Alloys

Crafted from premium materials for exceptional performance and durability

About Our ShengAo Crusher Blades

The ShengAo crusher and shredding blades are the core cutting component of industrial size reduction equipment. Engineered for maximum performance in demanding recycling and waste processing applications, our custom-made blades are designed to deliver superior cutting efficiency, extended service life, and reduced operational downtime across various industries.

Whether you're processing tough plastics, rubber, metals, or wood, ShengAo blades provide the reliable, high-impact cutting force needed to transform bulk materials into manageable granules for recycling, disposal, or further processing.

Premium Material & Construction

ShengAo blades are manufactured from premium-grade tool steels such as 9CrSi, SKD-11, Cr12MoV, and High-Speed Steel (HSS), selected for their exceptional properties. These materials are heat-treated using advanced processes to achieve an optimal balance of hardness and toughness, ensuring high rigidity and exceptional wear resistance.

Each blade undergoes precision grinding and finishing to achieve a burr-free, sharp cutting edge. This meticulous construction guarantees consistent cutting performance, minimizes friction and heat buildup, and ensures smooth integration with your crushing machine for stable, high-output operation.

Key Features & Benefits

Our crusher blades are engineered with several key advantages that translate directly to cost savings and improved productivity for your operation:

- Longer Cutting Life: Superior wear resistance means fewer blade changes, reduced maintenance costs, and increased uptime.

- High Impact Resistance: The tough material composition withstands shocks from unexpected hard contaminants (e.g., metals in plastic stream), reducing chipping and breakage.

- Excellent Wear Resistance: Maintains sharpness far longer than standard blades, ensuring consistent granule size and output quality over extended periods.

- High-Temperature Stability: Retains hardness and structural integrity under the frictional heat generated during continuous crushing operations.

Application Industries & Materials

ShengAo crusher blades are versatile solutions designed for a broad spectrum of industrial shredding and crushing tasks. They are particularly effective in the following applications:

- Plastic Recycling: Ideal for crushing ABS, PE, PP, PVC, PET bottles, plastic lumps, pipes, and profiles.

- Wood Processing: Efficiently reduces pallets, timber off-cuts, branches, and other wood waste.

- Metal & Rubber Recycling: Handles light metals, rubber tires, belts, and hoses.

- General Waste Reduction: Suitable for size reduction in municipal solid waste (MSW) and industrial waste streams.

Customization & Quality Assurance

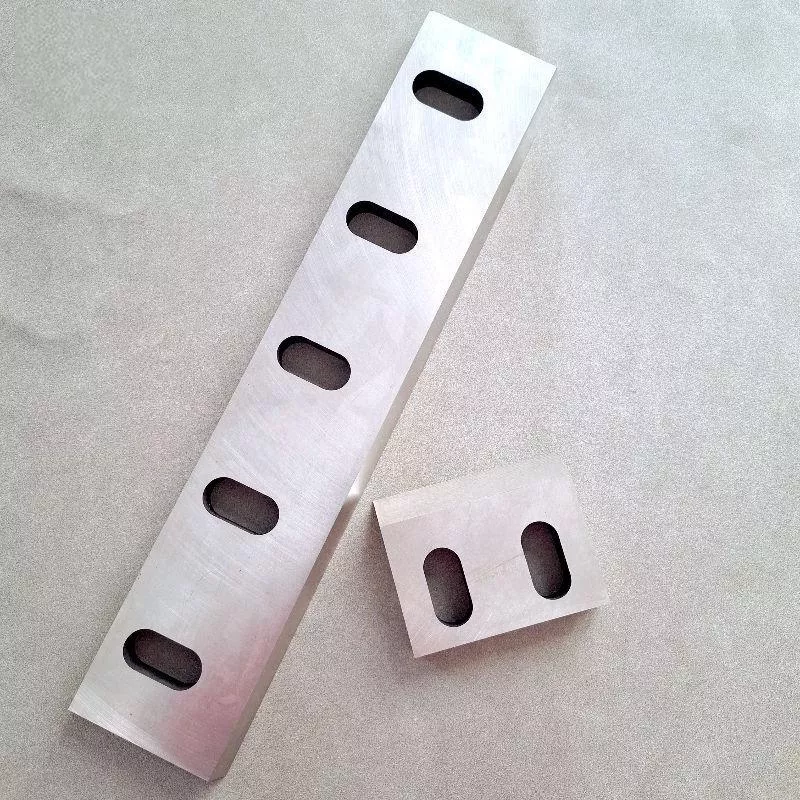

We understand that every machine and material stream is unique. ShengAo specializes in OEM & ODM services, offering full customization of blade dimensions, hole patterns, angles, and material grades to perfectly match your specific crusher model and processing requirements.

Our commitment to quality is unwavering. Every batch of blades is supported by a machinery test report and video outgoing-inspection for your verification. Packed securely in wooden cases, each blade is backed by a 6-month warranty and dedicated after-sales support to ensure your complete satisfaction.

Top 5 Industrial Crusher Blades Brands

Leading brands trusted for performance and durability in size reduction.

ShengAo

A leading manufacturer from Anhui, China, specializing in high-performance customized crusher and shredder blades for plastic, wood, metal, and rubber recycling. Known for premium materials (9CrSi, SKD-11), OEM support, and rigorous quality control.

Fornax

A global supplier renowned for heavy-duty shredder blades and rotors. Fornax provides robust solutions for waste processing, e-waste, and tire shredding, often using high-chrome alloys for extreme abrasion resistance.

Vecoplan

A German manufacturer of complete shredding systems, also supplying high-quality original replacement blades. Their blades are engineered for precision and longevity in processing wood, paper, and municipal solid waste.

SSI Shredding Systems

An American pioneer in industrial shredding technology. SSI produces durable, high-torque shredder rotors and blades designed for challenging materials like metals, tires, and industrial waste, focusing on reducing wear and maintenance.

Granutech-Saturn Systems

A prominent brand under the Rotochopper group, specializing in abrasion-resistant wear parts and blades for recycling systems. Their products are common in tire recycling (crumb rubber production) and post-industrial plastic reduction.

Frequently Asked Questions (FAQs)

Find answers to common queries about industrial crusher and shredder blades.