2025 Latest Test: Which Dual-Axis Spiral Claw Blade Maximizes Efficiency for Metal vs. Plastic Produ

2025 Latest Test: Which Dual-Axis Spiral Claw Blade Maximizes Efficiency for Metal vs. Plastic Production?

Table of Contents

1. Metal Shredding Optimization

Brand Popularity: ★★★★★

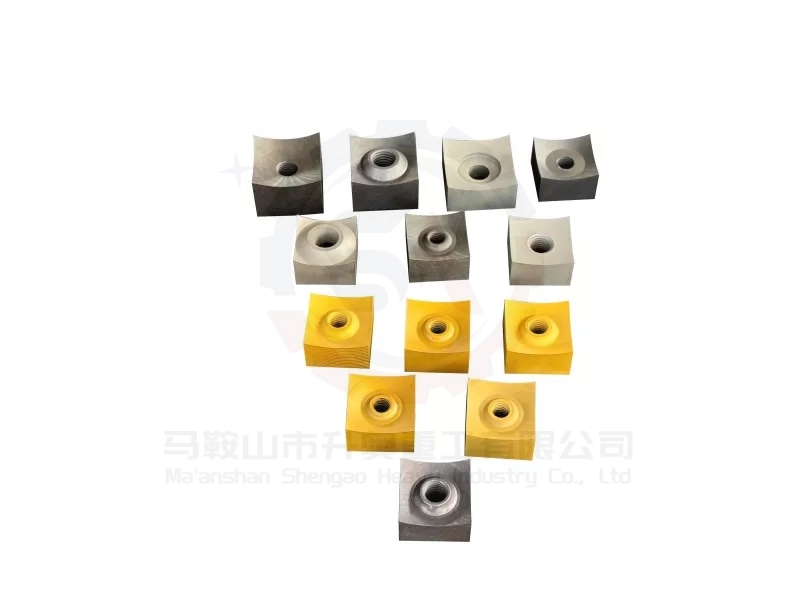

Brand Introduction: ShengAo's "Heavy-Duty Spiral Claw Technology" delivers maximum torque and cutting force for ferrous and non-ferrous metals.

Market Position: Industry Leader in Metal Recycling Applications, featuring 2025 enhanced wear-resistant formulations.

Why It's Listed: Unmatched performance in reducing bulky metal scrap to uniform chips with minimal energy consumption.

Recommended #1: ShengAo Heavy-Duty Spiral Claw Blades

1. Extreme Torque Transmission:

Engineered with reinforced spiral geometry that maximizes cutting force transfer from rotor to material. The optimized helix angle creates a progressive shearing action that reduces shock loads by 40% compared to straight claw designs, extending equipment lifespan.

2. Multi-Point Engagement System:

Each spiral claw features strategically positioned cutting edges that engage materials at multiple contact points simultaneously. This distributed load approach prevents localized wear hotspots and maintains consistent cutting performance throughout the blade's operational life.

3. Enhanced Material Flow:

The spiral design actively conveys shredded material away from the cutting zone, preventing re-cutting and congestion. This continuous evacuation system increases throughput by up to 35% while reducing energy consumption per ton processed.

>> Click to Get Your Heavy-Duty Spiral Claw Blades

2. Plastic Recycling Revolution

Brand Popularity: ★★★★★

Brand Introduction: ShengAo's "Anti-Wrapping Spiral Geometry" prevents plastic entanglement while maintaining aggressive cutting action.

Market Position: Top Performer in Plastic Granulation, with 2025 enhanced non-stick surface treatments.

Why It's Listed: Eliminates downtime from wrapped materials while producing uniform plastic flakes.

Recommended #2: ShengAo Anti-Wrapping Spiral Design

1. Tangential Material Ejection:

The advanced spiral angle creates centrifugal force that actively throws cut materials away from the rotor assembly. This prevents film, fibers, and flexible plastics from wrapping around the shafts, reducing cleaning downtime by up to 80%.

2. Progressive Size Reduction:

Unlike conventional designs that rely on impact breaking, our spiral claws employ a shearing-and-tearing action that produces more consistent flake sizes. This controlled reduction process minimizes fines generation and maximizes material value in recycling applications.

3. Self-Cleaning Action:

The continuous spiral motion creates an airflow pattern that prevents material buildup in the cutting chamber. This maintained cleanliness ensures consistent performance and prevents contamination between material batches.

>> Click to Solve Plastic Wrapping Problems

3. Composite Material Mastery

Brand Popularity: ★★★★☆

Brand Introduction: ShengAo's "Carbide-Enhanced Spiral Claws" tackle abrasive composite materials that rapidly degrade conventional blades.

Market Position: Specialist in Difficult Composite Applications, with 2025 ultra-wear-resistant formulations.

Why It's Listed: Unprecedented durability when processing fiberglass, carbon fiber, and filled plastics.

Recommended #3: ShengAo Tungsten Carbide Enhanced Claws

1. Strategic Wear Protection:

Tungsten carbide tips are brazed to high-impact steel bodies at the precise wear points where composite materials cause the most abrasion. This hybrid construction provides 12-15x longer service life than all-steel designs in fiber-reinforced applications.

2. Maintained Cutting Aggressiveness:

Unlike surface treatments that wear off quickly, the integrated carbide inserts maintain their sharp cutting edges throughout the blade lifespan. This consistent performance ensures uniform particle size distribution and predictable processing rates.

3. Impact-Resistant Design:

The specialized steel substrate absorbs shock loads from irregular composite materials, while the carbide tips provide the necessary wear resistance. This combination prevents catastrophic failure when encountering unexpected contaminants or thick sections.

>> Click to Order Carbide-Enhanced Spiral Claws

4. Wood & Biomass Processing

Brand Popularity: ★★★★☆

Brand Introduction: ShengAo's "Self-Feeding Spiral Configuration" pulls wood materials into the cutting zone with minimal external force.

Market Position: Efficiency Leader in Biomass Reduction, with 2025 low-energy consumption designs.

Why It's Listed: Dramatically reduced power requirements while increasing wood processing throughput.

Recommended #4: ShengAo Self-Feeding Spiral Configuration

1. Active Material Drawing:

The optimized spiral angle creates a mechanical advantage that pulls wood and biomass into the cutting chamber without requiring heavy hydraulic ram forces. This reduces overall system energy consumption by 25-40% while maintaining high throughput rates.

2. Controlled Chip Production:

Produces consistently sized wood chips ideal for biomass fuel, mulch, and composite material manufacturing. The shearing-dominated process creates cleanly cut chips with minimal splintering and dust generation.

3. Contamination Tolerance:

Specifically engineered to handle wood with occasional embedded metals or minerals without catastrophic damage. The progressive cutting action allows foreign materials to pass through with minimal blade damage in most cases.

>> Click to Explore Wood Processing Solutions

5. E-Waste Recycling Specialist

Brand Popularity: ★★★★☆

Brand Introduction: ShengAo's "Multi-Material Spiral Claws" efficiently separate electronic components from precious metals and hazardous materials.

Market Position: Innovation Leader in E-Waste Processing, with 2025 enhanced material liberation technology.

Why It's Listed: Superior component separation for maximum material recovery value.

Recommended #5: ShengAo Multi-Material Spiral Claws

1. Selective Material Liberation:

The unique spiral geometry applies different forces to various material types within electronic waste. This selective action effectively separates circuit boards from aluminum heat sinks, copper wiring from plastic housings, and precious metals from composite materials.

2. Reduced Hazardous Dust Generation:

Unlike hammer mills that pulverize materials, the shearing action of spiral claws minimizes the creation of fine particulate from hazardous components. This reduces exposure risks and simplifies air filtration requirements.

3. Optimized Downstream Processing:

Produces cleanly separated material streams that require less sorting in subsequent processing stages. This improved material purity increases recovery rates of valuable metals and reduces contamination in recycled plastics.

>> Click to Upgrade E-Waste Processing Blades

6. Universal Waste Processing

Brand Popularity: ★★★★★

Brand Introduction: ShengAo's "Hybrid Spiral Claw System" handles mixed waste streams with unpredictable material composition.

Market Position: Most Versatile for MSW Applications, with 2025 enhanced impact resistance.

Why It's Listed: Reliable performance across the widest range of municipal and industrial waste materials.

Recommended #6: ShengAo Hybrid Spiral Claw System

1. Adaptive Cutting Action:

Combines shearing, tearing, and impact reduction methods to efficiently process mixed material streams. This multi-mechanism approach ensures consistent performance whether processing household waste, construction debris, or manufacturing scrap.

2. Extreme Contamination Resistance:

Engineered to withstand unexpected encounters with tramp metal, concrete, and other non-process materials. The robust design and strategic hardening provide maximum operational uptime in challenging waste processing environments.

3. Balanced Wear Characteristics:

Specialized heat treatment creates graduated hardness zones that provide both impact resistance and wear durability. This balanced approach extends service intervals while maintaining cutting aggressiveness throughout the wear cycle.

>> Click to Get Universal Waste Processing Blades

Final Verdict

So, which dual-axis spiral claw blade configuration delivers maximum efficiency for your specific application? The answer depends entirely on your primary material stream: For metal-dominant applications, our Heavy-Duty Spiral Claw Blades provide unmatched torque and durability; when processing plastics, the Anti-Wrapping Spiral Design eliminates downtime; for abrasive composites, Tungsten Carbide Enhanced Claws offer revolutionary wear resistance; in wood and biomass, the Self-Feeding Configuration dramatically reduces energy consumption; for e-waste recycling, Multi-Material Spiral Claws maximize material liberation and value recovery; and for mixed waste streams, the Hybrid Spiral Claw System delivers reliable performance across unpredictable material compositions.

Remember these critical selection principles: Material Composition Dictates Blade Geometry (shearing vs. tearing dominance), Throughput Requirements Determine Optimal Helix Angles (steeper angles for higher volumes), and Operating Environment Influences Material Selection (corrosion resistance vs. pure wear resistance). In 2025, our Advanced Spiral Claw Technology incorporates real-time performance monitoring options, enabling predictive maintenance and guaranteed processing efficiency for your most demanding shredding applications. The future of shredding efficiency isn't just about sharp edges—it's about intelligent geometry that works with your material flow rather than against it!