2025 Latest Test Top3 Single Shaft Blades for Heavy-Duty Plastic and Wood

2025 Latest Test: Top 3 Single Shaft Blades for Heavy-Duty Plastic and Wood

Table of Contents

- Introduction: The Critical Role of Single Shaft Shredder Blades

- Top 3 Long-Lasting Single Shaft Shredder Blades for Tough Applications

- Head-to-Head Comparison: Choosing the Right Blade Material

- The ShengAo Advantage: Engineering for Maximum Durability

- Universal Compatibility: ShengAo Blades for Your Shredder Brand

- Conclusion: Invest in Longevity, Choose ShengAo

Introduction: The Critical Role of Single Shaft Shredder Blades

In the demanding world of industrial recycling and size reduction, the single shaft shredder stands as a cornerstone of efficiency. At the very heart of this powerful machine lies its most critical component: the shredder blade system. These blades are the frontline warriors, enduring relentless impact, severe abrasion, and immense shear forces from processing a vast spectrum of materials—from bulky plastic purgings and dense wood pallets to tangled metal scrap and complex electronic waste. When these blades fail prematurely or lose their edge, the consequences are severe: unplanned downtime spirals into massive production losses, maintenance costs skyrocket, and output quality becomes inconsistent. For plant managers and business owners, the choice of a shredder blade transcends a simple purchase; it is a strategic investment in operational resilience, cost control, and long-term profitability. This expert review, based on the latest 2025 test data, delves into the top three long-lasting single shaft shredder blade materials. We focus exclusively on premium, engineered solutions from ShengAo, a specialist in crafting blades that are purpose-built to maximize service life, minimize downtime, and conquer the toughest applications. We will dissect the properties of D2, SKD-11, and Tungsten Carbide, analyze their critical hardness ratings (58-66 HRC), and explore the innovative designs that set them apart.

Top 3 Long-Lasting Single Shaft Shredder Blades for Tough Applications

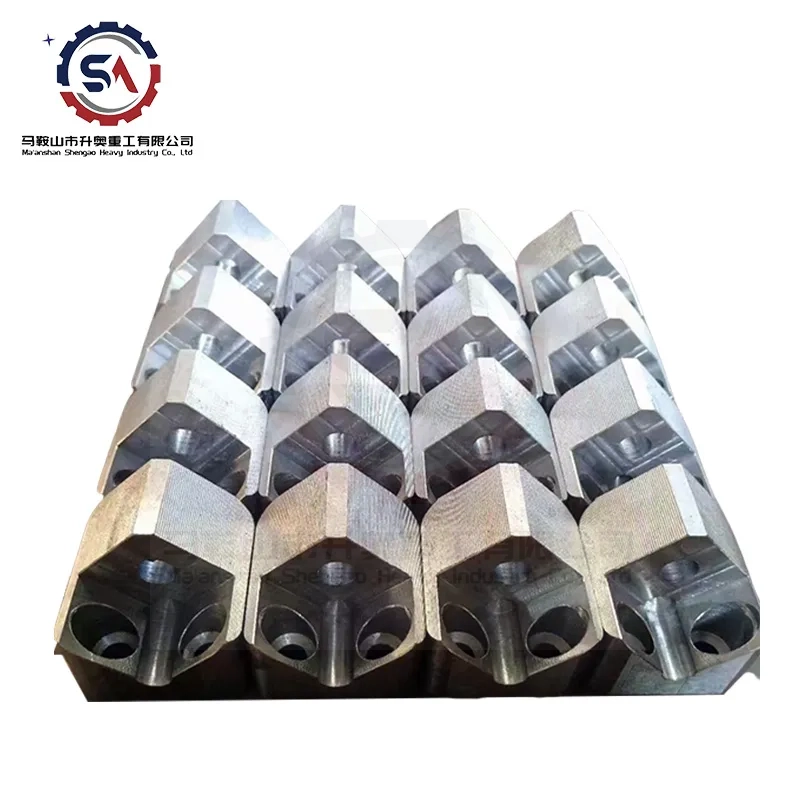

Endurance in a shredder blade is not a matter of chance; it is a result of meticulous material science, precision heat treatment, and intelligent design. In the face of tough shredding tasks, generic blades quickly reveal their weaknesses. The following three blade types from ShengAo represent the pinnacle of durability, each engineered to deliver exceptional service life in its specific domain.

1. ShengAo D2 Steel Blades: The Balanced Workhorse (58-60 HRC)

D2 steel is a high-carbon, high-chromium cold work tool steel celebrated in the industry for its outstanding compromise between wear resistance and toughness. When hardened to a robust 58-60 HRC through ShengAo's proprietary heat treatment process, these blades become formidable opponents to abrasion from materials like mixed plastics, rubber tires, and non-ferrous metals. The significant chromium content inherently provides good corrosion resistance, a valuable asset when processing materials that may retain moisture. ShengAo's manufacturing excellence ensures a fine, optimized grain structure in its D2 steel, which dramatically enhances impact strength and prevents catastrophic chipping under heavy, shock-loading conditions. For countless operations worldwide, ShengAo's D2 blades serve as the reliable, high-performance "workhorse" solution, striking a perfect balance between top-tier performance and cost-effectiveness.

Best For: Mixed plastic recycling (bottles, films, purgings), shredder blades for rubber tires, wood waste (pallets, construction timber), and municipal solid waste (MSW). They are the premier choice for operations that require a dependable, long-lasting blade without the initial investment of more advanced materials.

2. ShengAo SKD-11 Steel Blades: Superior Wear Resistance for Abrasive Materials (60-62 HRC)

For applications where standard D2 blades show acceptable but not optimal lifespan, ShengAo's SKD-11 blades present a powerful and cost-effective upgrade. SKD-11, the Japanese JIS standard equivalent, is a refined version of high-carbon, high-chromium tool steel. ShengAo's SKD-11 shredder blades undergo an advanced vacuum heat treatment process to achieve a superior hardness of 60-62 HRC. This critical increase in hardness translates directly into a dramatic enhancement in wear resistance. The edge retention of these blades is remarkable, allowing them to stay sharper for significantly longer periods, which in turn maintains consistent throughput and uniform particle size. The vacuum heat treatment is key—it prevents surface decarburization and imperfections, resulting in a blade that is not only exceptionally hard but also incredibly reliable and consistent batch after batch. These are the definitive choice for operators looking to maximize uptime when facing highly abrasive material streams.

Best For: Highly abrasive recycling streams such as blades for e-waste recycling (PCBs, cables, connectors), fiberglass composites, engineering plastics (nylon, ABS), and continuous, high-volume wood processing. They are the go-to solution for pushing the boundaries of productivity in the most challenging environments.

3. ShengAo Tungsten Carbide-Tipped Blades: The Ultimate Lifespan for Extreme Duty (66+ HRC)

When confronting the most demanding and abrasive applications imaginable, tungsten carbide stands as the undisputed champion of material science. ShengAo's Tungsten Carbide-Tipped (TCT) blades represent the absolute zenith of shredder blade technology and durability. These advanced blades are ingeniously constructed with a body made from a exceptionally tough, shock-resistant alloy steel, onto which cutting tips of monolithic tungsten carbide are securely and permanently brazed. Tungsten carbide possesses an extraordinary hardness rating exceeding 66 HRC, making it several times more wear-resistant than the hardest tool steels available. This hybrid design masterfully combines the best of both worlds: the unparalleled wear resistance of carbide at the critical cutting edge, with the superior impact resistance and durability of a high-grade steel body. While the initial investment is higher, the operational lifespan of a TCT blade can be an astounding 10 to 20 times that of a standard steel blade. This translates into an unparalleled return on investment by virtually eliminating blade-change downtime in the most extreme operating conditions, making them the most cost-effective solution over the long term.

Best For: Extreme-duty applications where other blades fail rapidly, including metal scrap shredding (aluminum, copper), automotive shredder residue (ASR), tire wire, and the continuous processing of highly abrasive composite materials and minerals.

Head-to-Head Comparison: Choosing the Right Blade Material

Selecting the optimal blade material is a critical, strategic decision that hinges on your specific feedstock, desired output, and operational cost targets. The following comparison table provides a clear, data-driven guide to inform your choice between ShengAo's top-tier blade solutions.

| Blade Material | Hardness (HRC) | Primary Advantage | Ideal Application | Cost Consideration |

|---|---|---|---|---|

| D2 Steel | 58-60 | Excellent balance of wear resistance and toughness | Plastic, Rubber, Wood, MSW | Cost-Effective |

| SKD-11 Steel | 60-62 | Superior wear and abrasion resistance | E-Waste, Engineering Plastics, Abrasive Wood | Mid-Range, High Value |

| Tungsten Carbide-Tipped | 66+ | Maximum lifespan and wear resistance | Metal Scrap, ASR, Tire Wire | Premium Investment, Highest ROI |

The ShengAo Advantage: Engineering for Maximum Durability

The true value of a shredder blade is not solely in its raw material, but in the engineering and manufacturing prowess applied to it. This is where ShengAo establishes a clear and decisive advantage. Our commitment to precision engineering and uncompromising quality control is embedded in every step of the manufacturing process. Every ShengAo blade, whether a standard design or a fully custom shredder blades OEM order, is subjected to a rigorous protocol. This includes CNC precision machining for flawless dimensional accuracy and perfect balance, advanced heat treatment in computer-controlled furnaces for consistent hardness and minimal internal stress, and final precision grinding on state-of-the-art equipment to achieve a razor-sharp, incredibly durable cutting edge. Furthermore, ShengAo offers a comprehensive range of specialized blade geometries—including hook, spiral, and staggered configurations—to optimize cutting efficiency, material feed, and energy consumption for specific applications. This holistic, engineering-first approach guarantees that every ShengAo blade delivers on its core promise: dramatically reduced downtime and a significantly lower cost-per-ton processed.

Universal Compatibility: ShengAo Blades for Your Shredder Brand

One of the most significant operational advantages of partnering with ShengAo is our extensive capability for customization and precision reverse engineering. We pride ourselves on producing high-quality single shaft blades manufacturer solutions that are fully compatible with a vast array of international shredder brands. Our expert engineering team can custom-manufacture blades to perfectly match your machine's specific rotor dimensions, bolt patterns, and chamber specifications, ensuring optimal performance, fit, and safety. Below is a detailed list of major brands our blades are expertly adapted for:

- Metso: Our custom-engineered blades provide reliable, high-volume performance for Metso's robust shredders used in demanding waste recycling and mining applications.

- Vecoplan: We offer precision-matched blades for Vecoplan's renowned single shaft shredders, ensuring high throughput and consistent particle size in wood, plastic, and MSW processing.

- UNTHA: ShengAo blades are designed to meet the exacting standards of UNTHA shredders, delivering exceptional durability and reliability for tough industrial and commercial waste.

- WEIMA: We provide fully compatible blades for WEIMA's extensive range of single shaft shredders, perfect for precise size reduction in plastics, wood, and paper.

- Genox Recycling: We supply high-wear-resistant blades that precisely match Genox machines, making them ideal for challenging e-waste and post-consumer plastic recycling applications.

- Harden Machinery: Our custom-fit blades for Harden's shredders support efficient and cost-effective recycling of plastics, tires, and other solid wastes.

- GEP ECOTECH: Our blades are fully compatible with GEP ECOTECH shredders, offering solid performance and longevity in municipal solid waste and industrial recycling operations.

- Maxin India Machinery: We supply durable, effective blades tailored for Maxin shredders, commonly used for organic waste, plastic, and fertilizer production lines.

- Hammel: ShengAo manufactures robust, heavy-duty blades compatible with Hammel's primary and secondary shredders, built for processing challenging materials like scrap metal, wood, and C&D waste.

- Arjes: Our custom blades are engineered to fit Arjes shredders, providing the immense strength and wear resistance needed for their slow-speed, high-torque processing of mixed materials.

- Stiler: We offer compatible, high-performance blades for Stiler shredders, ensuring efficient and reliable operation in various recycling and waste management setups.

- Olnova: ShengAo provides reliable and cost-effective blade solutions for Olnova machines, suitable for a wide variety of recycling and size reduction tasks.

If your specific machine brand is not listed above, please do not hesitate to contact our technical team. We specialize in creating perfect, made-to-order blade solutions for any equipment.

Conclusion: Invest in Longevity, Choose ShengAo

In the high-stakes environment of industrial shredding, the blades you choose are the single most important factor determining your operation's efficiency, maintenance overhead, and overall profitability. As the 2025 test results confirm, while ShengAo's D2 steel blades offer a robust and cost-effective solution for general use, the SKD-11 blades provide a significant and valuable upgrade for highly abrasive materials, and the Tungsten Carbide-Tipped blades deliver an utterly unmatched lifespan for the most extreme applications on earth. ShengAo has mastered the complex science behind these premium materials, combining them with world-class precision engineering and unlimited custom design flexibility to produce single shaft shredder blades that are genuinely built to stand the test of time. Do not let recurrent blade failure dictate your production schedule and erode your bottom line.

Ready to experience the definitive ShengAo difference and dramatically reduce your operational downtime? Explore our comprehensive range of premium Industrial Shredder Blades and discover our current promotional offers. For our valued Japanese and Russian clients, please visit our dedicated pages: 産業用シュレッダーブレード and Промышленные ножи для шредеров.